Adele

MUSIC PAPER 2 GRADE 12 MEMORANDUM - NSC EXAMS PAST PAPERS AND MEMOS NOVEMBER 2018

MUSIC

PAPER 2

GRADE 12

NSC EXAMS

PAST PAPERS AND MEMOS NOVEMBER 2018

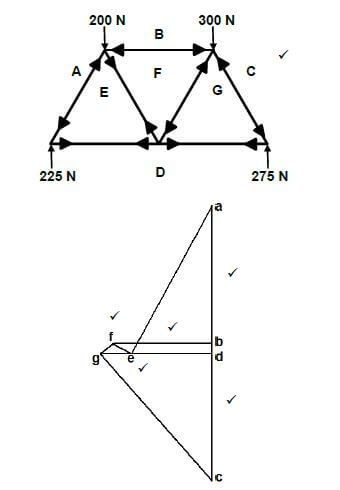

MEMORANDUM

Note to the marker: Candidates must be credited for any correct answers not given in the marking guidelines. |

SECTION A: AURAL

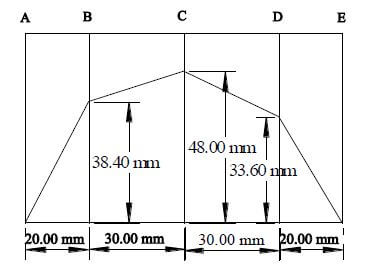

QUESTION 1

1.1 Listen to the melodic and rhythmic phrase. Notate the rhythm of the missing notes in bars 2–3 below.

Answer: ![]() (3)

(3)

1½ mark per bar as indicated = 3 marks |

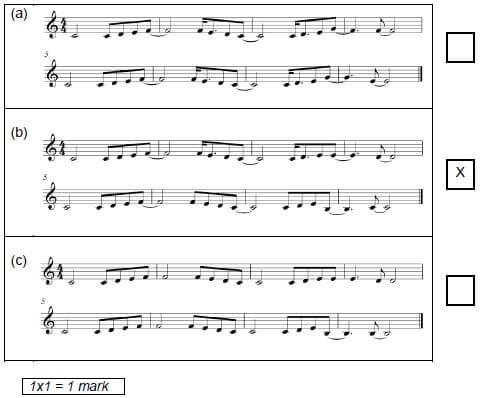

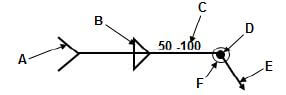

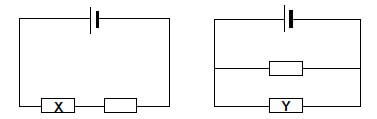

1.2 Which ONE of the notations below best represents the solo voice part? Make a cross (X) in the appropriate block.  (1) [4]

(1) [4]

QUESTION 2

Listen to the extract below and answer the questions that follow.

2.1 Name the interval formed between the Db note and the missing note in bar 24.

- Answer: Perfect 4th (1)

2.2 Which type of non-chordal note do you hear in bar 54?

- Answer: Anticipation (1)

2.3 Name the cadence at bars 11 to 12.

- Answer: Perfect cadence (1)

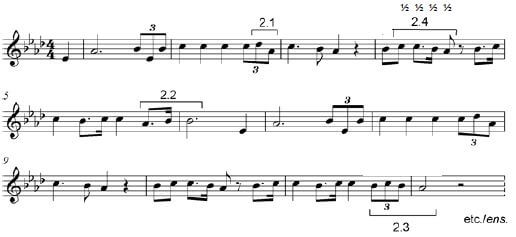

2.4 Listen to the music from bars 1 to 6. Some of the notation in bar 4 has been omitted from the score. Fill in the missing pitches and note values that correspond with the music that you hear.

- Answer: See score (2)

Correct pitches and note values = ½ mark each No mark for correct pitch or note value only |

2.5 Name the solo instrument that plays the melody line in this extract.

- Answer: Trumpet (1) [6]

TOTAL SECTION A: 10

SECTION B: RECOGNITION OF MUSIC CONCEPTS

QUESTION 3: GENERAL LISTENING (COMPULSORY)

Listen to the following tracks and answer the questions that follow.

Note to marker: if a candidate selected more items than requested, only the first answers must be marked. |

3.1 With which items in COLUMN A do you associate the music that you hear in Track 7? Make a cross (X) in THREE appropriate blocks.

Answer:

COLUMN A | Track 7 |

Chromatic passage | X |

Adagio | |

Duet | |

Allegretto | X |

String and wind quartet | |

Major key | X |

String quartet | X |

3x1 = 3 marks |

3.2 Which ONE of the following statements is correct? Make a cross (X) in the appropriate block.

Answer:

Statement | |

The extract consists of a motif, an imitation and an imperfect cadence | X |

The extract consists of a motif, inversion and an imperfect cadence | |

The extract consists of a motif, repetition and an imperfect cadence |

1 mark |

3.3 With which items in COLUMN A do you associate the music that you hear in Track 9? Make a cross (X) in THREE appropriate blocks.

Answer:

COLUMN A | Track 9 |

Vocal melody starts with an anacrusis | X |

Triple time | |

Quadruple time | X |

Swing/shuffle rhythm | X |

Guitar introduction | |

12-bar blues | |

Syllabic word setting | X |

3x1 = 3 marks |

3.4 With which items in COLUMN A do you associate the music that you hear in Track 10? Make a cross (X) in THREE appropriate blocks.

Answer:

COLUMN A | Track 10 |

Chordal accompaniment | X |

Allegro | |

Simple quadruple | X |

Compound triple | |

Guitar introduction | X |

Straight rhythm | X |

Alto voice | X |

3x1 = 3 marks |

3.5 Choose any TWO items in COLUMN A and identify what you hear, in COLUMN B.

Answer:

COLUMN A | COLUMN B (IDENTIFY) |

Solo instrument | Pennywhistle |

Prominent compositional technique | Repetition |

Musical genre | Kwela |

Texture | Homophonic |

2x1 = 2 marks |

(12 ÷ 3 =) [4]

Answer QUESTION 4 (WAM) OR QUESTION 5 (JAZZ) OR QUESTION 6 (IAM).

QUESTION 4: WAM

4.1 With which ONE of the following characters in COLUMN A do you associate EACH track? Make a cross (X) in the appropriate block for each track.

Answer:

COLUMN A | Track 12 | Track 13 | Track 14 |

Papageno | X | ||

Tamino | X | ||

Sarastro | X | ||

Monastatos | |||

Pamina |

3x1 = 3 marks |

4.2 Give a suitable Italian term to describe the tempo of the music in this extract.

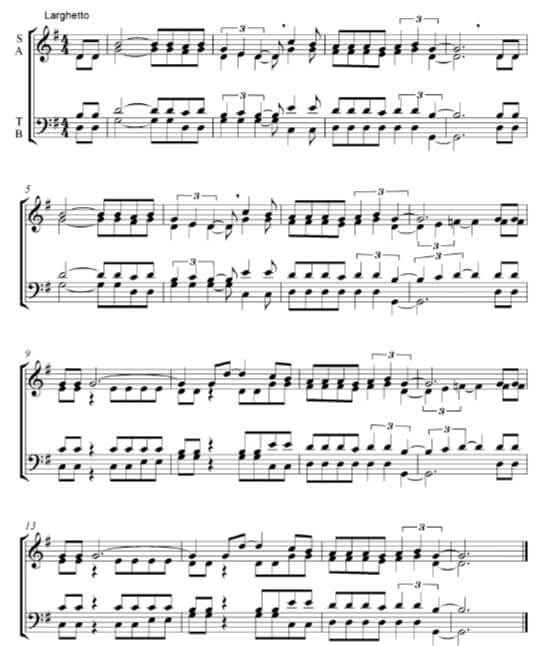

- Answer: Largo/Larghetto/Adagio (1)

4.3 Name the wind instrument heard at the end of this extract.

- Answer: Flute (1)

4.4 Which item describes the compositional technique used in this extract? Choose from the list below. Make a cross (X) in the appropriate block.

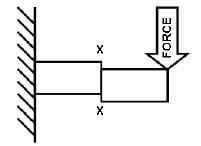

Answer: ![]() (1)

(1)

4.5 What is the title of the movement from which this extract is taken?

- Answer: Awakening of cheerful feelings upon arrival in the countryside (1)

4.6 Which solo wind instrument plays the melody?

- Answer: Clarinet (1)

4.7 Which wind instrument plays an accompaniment to this melody at the start of this extract?

- Answer: Bassoon (1)

4.8 Describe how Beethoven employs the string section in this extract.

Answer:

- Forms part of the accompaniment

- Interjecting/punctuating two chords at the end of each subphrase (cadences)

- The two chords are played accented or > or detached

- Decrescendo/Diminuendo at the end of the track

- Features in the Introduction

- Alternating playing between strings and winds

- Employs homophonic texture

2x1 = 2 marks |

4.9 Choose THREE statements below that best describe the music that you hear. Make a cross (X) in THREE appropriate block.

Answer:

All instruments play in unison | |

Ascending legato passages | X |

Ascending chromatic scale passages | X |

Ascending chromatic sequences in clarinets | |

Long sustained note | X |

Clarinet solo |

3x1 = 3 marks |

4.10 Write down the title of the work from which this extract is taken.

- Answer: Hebrides Overture/Fingal's Cave (3)

(Lonely Island) = ½ mark(1)

4.11 Identify from which part of the work this extract is taken. Choose from the list below and make a cross (X) in the appropriate block.

Answer:

Part of work | Answer |

First subject/theme | |

Second subject/theme | |

End of the development | X |

Beginning of the coda |

1x1 = 1 mark |

(16 ÷ 2=) [8]

TOTAL SECTION B: 12

OR

QUESTION 5: JAZZ

5.1 With which FOUR items in COLUMN A do you associate the music that you hear? Make a cross (X) in FOUR appropriate blocks.

Answer:

COLUMN A | Answers |

Mbaqanga | |

Pentatonic | |

Major | X |

Simple quadruple | X |

12-bar blues | |

Cape Jazz | X |

| X |

Kwela | |

Harmonic chord cycle | X |

4x1 = 4 marks |

5.2 Which item describes the melodic movement of the horn section? Make a cross (X) in the appropriate block.

Answer:

Chromatic passage | |

Group improvisation | |

Ascending sequences | |

Descending sequences | X |

1 mark |

5.3 Apart from the drum kit, name ONE other instrument that forms part of the rhythm section in this extract.

- Answer: Bass guitar/Rhythm guitar/Piano (1)

5.4 With which one of the South African solo artists do you associate this extract? Make a cross (X) in the appropriate block.

Answer: ![]()

5.5 With which THREE items in COLUMN A do you associate the music that you hear? Make a cross (X) in THREE appropriate blocks.

Answer:

COLUMN A | Answers |

Fuses Xhosa songs with blues | |

Abdullah Ibrahim influences | X |

Idiophone | X |

Modal chord progression | X |

Improvisation | |

Ceremonial atmosphere | X |

Answer:

3x1 = 3 marks |

5.6 Describe the role of the piano in this extract.

Answer:

- Provides short introduction

- Plays the ostinato

- Plays short melodic riffs

- Provides rhythmic drive

- Provides an African percussive timbre

- Provides harmonic basis (modal chords)

Any TWO correct answers = 2 marks |

5.7 Name the instrument that plays the accompaniment in the introduction of this extract.

- Answer: (Rhythm) guitar/banjo/double bass (1)

5.8 Describe the role of the backing singers.

Answer:

- provides harmonic support

- Adds tone colour (male voices)

- Thickens texture (new layer of sound)

Any TWO correct answers = 2 marks |

5.9 Name ONE group that you associate with this jazz style.

Answer:

- The Manhattan Brothers

- The Merry Blackbirds

Any ONE correct answer = 1 mark |

OR

(16 ÷ 2=) [8]

TOTAL SECTION B: 12

QUESTION 6: IAM

6.1 With which FOUR items in COLUMN A do you associate the music that you hear? Make a cross (X) in FOUR appropriate blocks.

Answer:

COLUMN A | Answer |

Mbaqanga | |

Modal | X |

Malombo | |

Umrhube | X |

Ululation | X |

Major | |

Aerophone | X |

Concertina | |

Repetition | X |

4x1 = 4 marks |

6.2 Describe the whistling that you hear.

Answer:

- Provides melodic material over marimba accompaniment

- Has an improvisational character

- Glissandi

- There are multiple (3-4) whistles (polyphonic)

- Call and response

Any correct answer = 1 mark |

6.3 Write down a suitable term to describe the rhythmic feature in the accompaniment.

Answer:

- Polyrhythms/Cross rhythms

- Repetitive overlapping rhythmic pattern.

Any correct answer = 1 mark |

6.4 With which THREE items in COLUMN A do you associate the music that you hear? Make a cross (X) in THREE appropriate blocks.

Answer:

COLUMN A | Answer |

Blues | |

Batswana | X |

Idiophone | X |

Malombo drum | |

Chord cycle | X |

Tshikona |

Correct answers = 3 marks |

6.5 Identify the differences between Track 29 and Track 30. Choose only TWO items in column A for your comparison.

Answer:

COLUMN A | Track 29 | Track 30 |

Introduction | Organ/Keyboard prominent | Guitar prominent ` |

Drum kit enters later during the introduction | Drum kit features from the beginning | |

Voice type | Male singers only (solo and backing vocals) | Female singers (SSA) and a solo male singer (baritone/Idoshaba/Umngqokolo) |

Tempo/Beat | Relaxed beat | Energetic driving beat |

(Medium tempo) | (Fast tempo) |

Any TWO correct correlated differences = 2 x 2 = 4 marks No marks awarded if direct comparison is not made |

6.6 Name the style that you associate with both extracts.

- Answer: Mbaqanga (1)

6.7 With which artists/bands do you associate each track?

Answer:

- Track 29: Soul Brothers

- Track 30: Mahlathini and the Mahotella Queens/Cool Crooners

2x1 = 2 marks |

(16 ÷ 2=) [8]

TOTAL SECTION B: 12

SECTION C: FORM

QUESTION 7

Read and study the questions for ONE minute.

Listen to the piece below while you study the score.

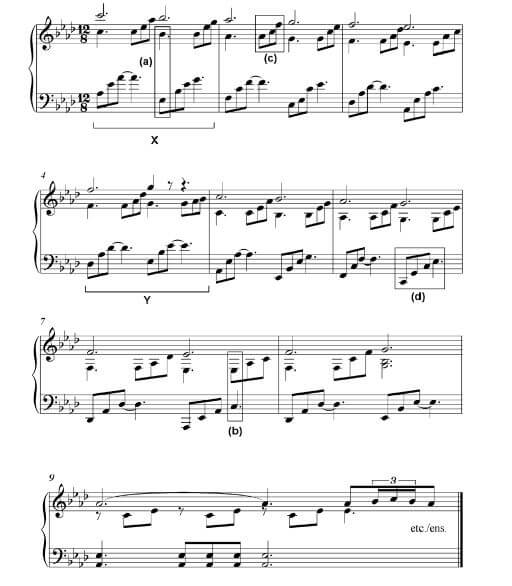

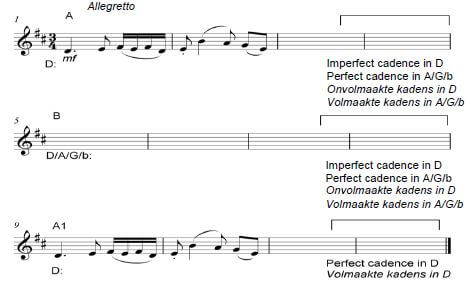

7.1 Name the form type of this piece?

- Answer: AB/Binary (1)

7.2 Motivate your answer to QUESTION 7.1 by giving a schematic layout of the form of this piece. Use the table below.

Answer:

Section | Bar numbers |

A | 1–8 or 04–83 |

B | 84 – 163 |

1 mark for each correct section = 2 marks 1 mark for correct bar numbers of each section = 2 marks |

7.3 Name the texture type of this extract.

- Answer: Homophonic (1)

7.4 What is the function of the F natural in bar 8?

Answer:

- It shows a temporary/short modulation to C Major

- The lowered leading note of G major suggests a secondary dominant, V7/IV

Any correct answer = 1 mark Modulation = ½ mark |

7.5 Which ONE of the following features is used in this piece? Make a cross (X) in the appropriate block.

Answer: ![]() (1) [8]

(1) [8]

TOTAL SECTION C: 8

GRAND TOTAL: 30

MUSIC PAPER 1 GRADE 12 MEMORANDUM - NSC EXAMS PAST PAPERS AND MEMOS NOVEMBER 2018

MUSIC

PAPER 1

GRADE 12

NSC EXAMS

PAST PAPERS AND MEMOS NOVEMBER 2018

MEMORANDUM

SECTION A: THEORY OF MUSIC (COMPULSORY) (90 minutes)

Answer QUESTION 1

AND QUESTION 2.1 OR 2.2

AND QUESTION 3.1 OR 3.2

AND QUESTION 4.1 OR 4.2.

QUESTION 1 (25 minutes)

Study the extract and answer the questions that follow.

1.1 Name the submediant minor key of this piece.

- Answer: F (minor) (1)

1.2 Name the related dominant major key of this piece:

- Answer: Eb(major) (1)

1.3 Name the intervals at (a) and (b) according to type and distance. Answer:

- Compound Perfect 5th/Perfect 12th

- Minor 3rd (2)

1.4 Transpose the bass part of bar 1 at X a perfect 5th lower. Insert the new key signature.

Answer:  (3)

(3)

Correct key signature = 1 mark |

1.5 Describe the triads at (c) and (d) according to type and position.

Answer:

(c) Minor, First inversion

(d) Minor, Root position(2)

2x½ = 1 mark |

1.6 Halve the note values and rewrite the bass clef part at Y in bar 4. Insert the new time signature.

Answer:  (3)

(3)

Time signature = 1 mark |

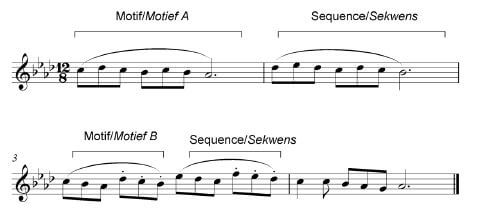

1.7 Complete the melody below by writing ascending sequences as indicated.

Answer:  (4)

(4)

Motif A = 2 marks |

1.8 Select the scale/mode on which each of the following TWO extracts is based. Make a cross (X) in the appropriate block.

1.8.1 Answer: Dorian mode (1)

1.8.2 Answer: Whole-tone scale (1)

1.9 Write F# melodic minor scale ascending and descending without key signature in the given clef. Use only semibreves and indicate the semitones.

Answer: ![]() (2) [20]

(2) [20]

Ascending = 1 mark |

QUESTION 2 (25 minutes)

Answer EITHER QUESTION 2.1 OR QUESTION 2.2.

2.1 Complete the opening below to form a twelve-bar melody in ternary form for any single-line melodic instrument of your choice. Name the instrument and supply a suitable tempo indication. Add dynamic and articulation indications where applicable.

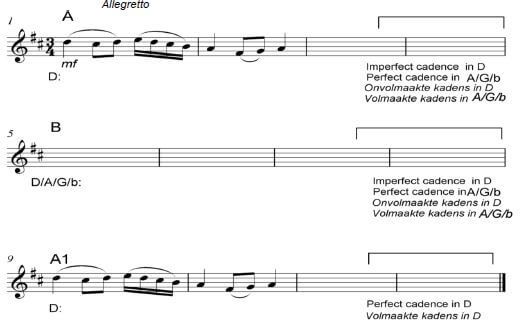

Concept answer: Instrument: Saxophone/Clarinet/Trumpet/Violin/Flute/Oboe/Horn, etc. Allegretto

OR

2.2 Complete the opening below to form a twelve-bar melody in ternary form for any single-line melodic instrument of your choice. Name the instrument and supply a suitable tempo indication. Add dynamic and articulation indications where applicable.

Concept answer: Instrument: Saxophone/Clarinet/Trumpet/Violin/Flute/Oboe/Horn, etc.

The melody will be marked according to the following criteria: [15]

DESCRIPTION | MARK ALLOCATION | ||

Form and cadential points | 1 mark per phrase x 3 | 3 | |

Correctness | Minus ½ mark per error up to 2 marks | 2 | |

Quality

| 9–10 | Excellent | 10 |

7–8 | Good | ||

4–6 | Average | ||

0–3 | Not acceptable | ||

TOTAL | Markers may use ½ marks | 15 | |

QUESTION 3 (10 minutes) Answer EITHER QUESTION 3.1 OR QUESTION 3.2.

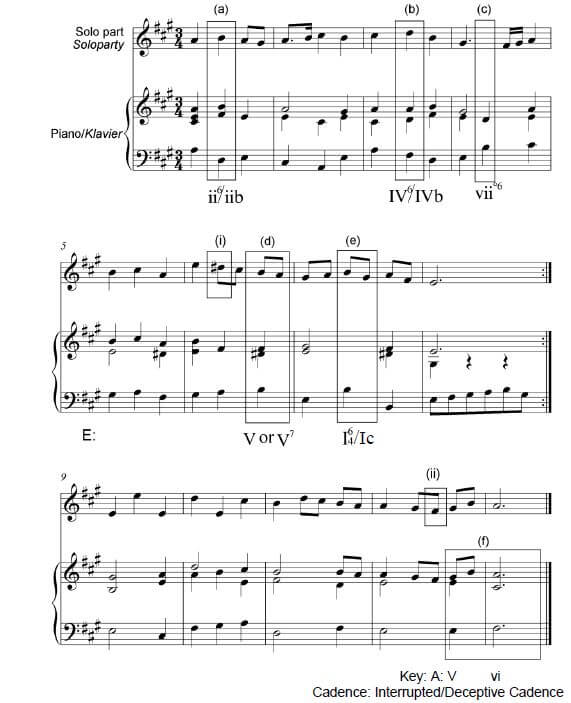

3.1 Study the extract and answer the questions.

Answer:

3.1.1 Name the new key to which the piece modulates in bars 5–8. Write the answer on the score.

- Answer: See score (1)

3.1.2 Figure the chords at (a)–(e) with Roman numerals on the score, e.g. iii6/iiib

- Answer: See score (5)

1 mark per chord = 5 marks |

3.1.3 Identify the cadence at (f) in bars 12–13 on the score. Indicate the key and figure the chords with Roman numerals.

- Answer: See score (2)

½ mark for key | = 2 marks |

3.1.4 Name the type of non-chordal notes at (i) and (ii).

- Answer (i) Passing note

(ii) Auxiliary note/Neighbouring note(2) [10]

OR

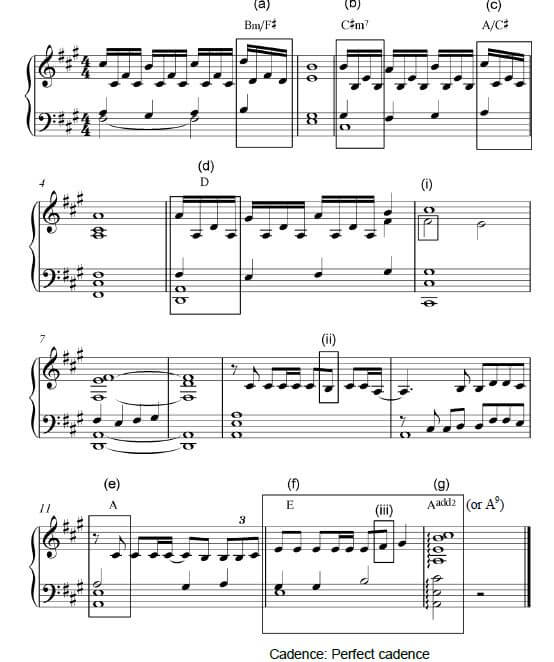

3.2 Study the extract and answer the questions.

Answer:

3.2.1 Identify the chords (a)–(e) and write chord symbols in the spaces provided on the score, e.g. Bb/D.

- Answer: See score (5)

1 mark per chord = 5 marks |

3.2.2 Name the types of non-chordal notes at (i)–(iii).

- Answer: (i) Suspension

(ii) Auxiliary/Neighbouring note

(iii) Passing note(3)

3.2.3 Name the cadence which is formed in bars 12–13 on the score. Indicate the chord symbols at (f) and (g).

- Answer: Perfect cadence, E – Aadd2 (or A9) (2) [10]

Cadence = 1 mark | = 2 marks |

QUESTION 4 (30 minutes)

Answer EITHER QUESTION 4.1 OR QUESTION 4.2.

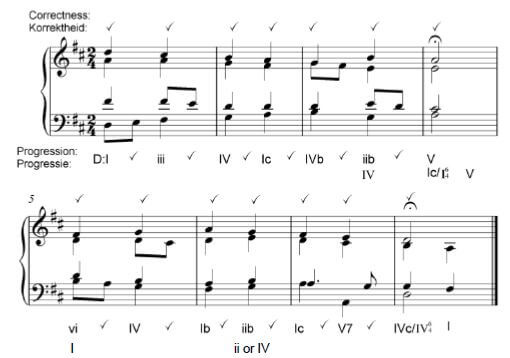

4.1 Complete the four-part vocal harmonisation below by adding the alto, tenor and bass parts.

Concept answer:

The harmonisation will be marked according to the following criteria:

DESCRIPTION | MARK ALLOCATION | |

Chord progression | 1 mark between each pair of chords (except between bars 4, 5 and 8) | 12 |

Correctness | Minus ½ mark per error but not more than 1 mark per chord | 14 |

Quality | Excellent = 3½–4 marks | 4 |

Note to marker: | 30 (÷ 2) | |

TOTAL | 15 | |

Candidates must be credited for a different/creative and correct harmonisation not given in the marking guidelines. The figuring serves as a guide for the marker, but no marks are allocated for the symbols as such.

OR

4.2 Complete the piece below by adding suitable harmonic material in the open spaces on the stave. Continue in the style suggested by the given material in bars 1 and 2.

Concept answer:

The answer will be marked according to the following criteria:

DESCRIPTION | MARK ALLOCATION | |

Chord progression | 1 mark between each pair of chords | 14 |

Correctness | Minus ½ mark per error but not more than 1 mark per chord | 12 |

Quality | Excellent = 3½–4 marks | 4 |

Note to marker: | 30 (÷ 2) | |

TOTAL | 15 | |

Candidates must be credited for a different/creative and correct harmonisation not given in these marking guidelines. The figuring serves as a guide for the marker, but no marks are allocated for the chord symbols as such.

TOTAL SECTION A: 60

SECTIONS B, C, D, E: GENERAL MUSIC KNOWLEDGE (90 minutes)

Answer SECTION B

AND SECTION C (Western Art Music)

OR SECTION D (Jazz)

OR SECTION E (Indigenous African Music).

Note to marker: One mark will be allocated for each correct fact. Candidates must be credited for any correct answer not given in these marking guidelines. Regardless of the fact that this marking guideline is constructed in bullet form, it is expected that the candidate answers the questions in paragraph/essay form where required. |

SECTION B: GENERAL (COMPULSORY)

QUESTION 5

5.1

5.1.1 B

5.1.2 C

5.1.3 D

5.1.4 B

5.1.5 D

5.1.6 D

5.1.7 D

5.1.8 B

5.1.9 C

5.1.10 B (10)

5.2

5.2.1 B

5.2.2 A

5.2.3 E

5.2.4 C

5.2.5 D (5)

FIVE correct answers = 5 marks |

5.3 ∙ Song writer/composer

- Performer/singer/band member/session musician

- Sound engineer

- Editor/director

- Recording engineer

- Producer/recording company

- Arranger

- Lyricist (5)

Any FIVE correct answers = 5 marks |

[20]

TOTAL SECTION B: 20

Answer SECTION C (WAM)

OR SECTION D (JAZZ)

OR SECTION E (IAM).

SECTION C: WESTERN ART MUSIC (WAM) QUESTION 6

6.1

- Clarinet

- French Horn

- Trumpet (2)

TWO correct answers = 2 marks |

6.2 Clarinet (1)

6.3

- Two

- Timpani/Kettle drums(1)

6.4 (3)

Codetta | Coda | |

Where in the work | Found at the end of the exposition | Found at the end of the recapitulation |

Key | Ends in a related key | Ends in the tonic key |

Function | Tail section as ending and rounding off the exposition | Tail section to end off the movement |

Length | Usually a short section | Sometimes short, but often an extensive section |

Structural function | Usually in the form of a repeated (extended) cadence (in new key) | New material introduced or previously stated material may be developed with extended cadence at the end |

Any THREE correct correlated differences = 3 marks Candidates may answer in table format |

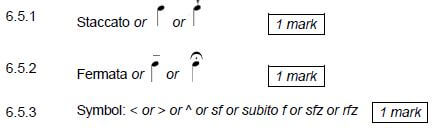

6.5

6.5.1  [10]

[10]

QUESTION 7

7.1 In Diesen Heil'gen Hallen/Within these Hallowed Halls (1)

7.2

- Sung by Sarastro – a symbol of good

- Bass voice – reinforces stable attitude

- Act 2 – contrasts with the Queen of the Night's vengeful second aria

- Fairly slow tempo: Larghetto – to reinforce 'holiness' of the temple

- Key: E major – to establish a positive, reassuring atmosphere

- Form: 2 verses – simplicity of form reinforces calm, stable mood

- Use of melismas

- Mood: serious, calm and reassuring

- Sarastro sings of love, duty and forgiveness / ideals of brotherhood

- Instrumentation: 2 flutes, 2 bassoons, 2 horns, string section

FOUR correct facts = 4 marks |

QUESTION 8

- Established the layout of the standard Classical orchestra

- Arrangement of the standard Classical orchestra into 4 instrument groups

- Each section of orchestra given a particular role

- Large string section with violins playing the principle melody

- Doubled instruments in woodwinds (excluding clarinet) as a binding/filling role

- Woodwinds as melodic instruments

- Restricted use of brass and percussion (two timpani) for the ff sections

- Basso continuo was omitted

- The bass part is given a stronger forward rhythmic drive

- French Horns act as a harmonic binding agent

- Introduced the four movement symphony

- Performance techniques developed

- Tremolo

- Sudden sfz

- Opening arpeggios

- Crescendos and decrescendos

- Playing techniques: The rocket- and sigh-motives [5]

Any FIVE correct facts |

QUESTION 9

Instrumentation

- Increases number of instruments in orchestra

- Use of timpani more for dramatic effect than for harmonic reinforcement

- Piccolo adds colour to the exhilaration and tension

- Trombones added for intensity and power of sound colour and range Dynamics

- Greater range and extremes of dynamics are used than before (pp – ff)

- ff in tremolos of string passages

- pp string passage at end of the symphony

- Sudden changes in dynamics for dramatic purposes e.g. fortepiano fp

- More use of accents (sf) and climaxes

- Extensive use of crescendi and decrescendi in successive 'waves'

- Extended orchestration to increase dynamic possibilities [5]

Any FIVE facts as long as both dynamics and instrumentation are included = 5 marks |

QUESTION 10

Answer:

Origin

- Composed as a result of a visit to Scotland – the Hebrides islands

- Inspired by a cavern known as Fingal's Cave and the surrounding seascape, even made sketches of the island

- A boat ride to these islands had a huge impact on him

- He wrote letters to his sister describing this emotional experience

- Completed in 1830 (The Lonely Island), revised and renamed in 1833

Any THREE correct facts = 3 marks |

Description of composition

Form

- Concert overture

- An independent single movement work

- Sonata form OR Allegro-Sonata form

- Exposition: B minor - D Major

- Development: D Major

- Recapitulation: starts in B minor; includes new material in bridge; 2nd subject in B Major; extended Coda

- The bridge passages are greatly extended

Only 1 mark for keys |

Instrumentation/Orchestration

- A work for standard Classical orchestra

- Innovative orchestration resulted in new combinations of colour and mood e.g. use of upper pedal points

- No additional instruments as was the case in most other Romantic orchestral works

- Both themes are played by the lower register instruments (cello, bassoon, viola)

- Demands greater technical competence from the orchestral players

- Instrumentation/orchestration contribute to the mood

- the murmur of the sea depicted by the tremolo in the strings

- the crashing waves depicted by sforzandi chords for the orchestra tutti

- the sea swells depicted by the movement of the opening theme played by cello, viola and bassoon

Any THREE correct facts = 3 marks |

Style

- Use of chromaticism

- Extreme dynamic contrasts

- A dramatic symphonic work with programmatic content

- Texture: Mostly homophonic

- Tempo: Allegro moderato

- Tempo fluctuations - rubato

- Programmatic nature and sets a scene but does not tell a story

Any THREE correct facts = 3 marks |

Logical presentation and structure of the essay = 3 marks |

The essay will be marked according to the following criteria:

CRITERIA | MARK ALLOCATION | ||

Origins | 3 marks | 3 | |

Form | 3 marks | 3 | |

Instrumentation/ Orchestration | 3 marks | 3 | |

Style | 3 marks | 3 | |

Logical presentation and structure of the essay | Excellent | = 3 marks | 3 |

Good | = 2–2½ marks | ||

Average | = 1½ marks | ||

Below average | = 1 mark | ||

Weak | = ½ mark | ||

Not acceptable | = 0 marks | ||

TOTAL | 15 | ||

[15]

TOTAL SECTION C: 40

SECTION D: JAZZ

QUESTION 11

11.1

- Trumpet

- Saxophone

11.2

- Keyboard/organ

- Guitar

- Bass guitar

- Drum kit

Any TWO correct answers = 2 marks |

11.3 (4)

POPULAR SONG FORM | BLUES FORM |

32 bars | 12 bars (with lyrics in AAB form) |

AABA form/Verse and chorus | One part form |

Diatonic chord progression e.g. A: I-vi-IV-V B: V7/vi - V7/ii - V7/V - V7 | I7, IV7 and V7in a 12-bar cyclic scheme (All chords have a minor seventh added) F7(4 bars), Bb7(2 bars), F7(2 bars), C7(1 bar), Bb7(1 bar), F7(2 bars) |

Two contrasting themes | One theme |

Any TWO correct correlated differences 2 x 2 = 4 marks Candidates may answer in table format |

11.4

11.4.1 Improvisation/Jamming (1)

11.4.2

- Comping

- Improvisational chordal accompaniment (1)

Correct fact = 1 mark |

11.4.3 Substitution (1) [10]

QUESTION 12

Answer:

Characteristics

- A unique fusion of African jazz with rhythms and melodies of traditional vhaVenda and baPedi music

- Melodies, percussion and language derived from baPedi and vhaVenda cultures ∙ Prominent use of African polyrhythms

- African rhythms supplied by the bongo, malombo and meropa

- Lyrical, lilting guitar and flute melodies are extensively used

- Free jazz, blues and rock influences from North America

- Guitar arrangements and improvisatory style are borrowed from musicians such as Wes Montgomery and John McLaughlin

- 12-bar blues structure employed in some compositions

Any FOUR characteristics = 4 marks |

Artist/Band

- Philip Tabane

- Julian Bahula

- Malombo Men

- Malombo Jazz [5]

Any ONE artist/band = 1 mark |

QUESTION 13

Answer:

Marabi

- Both vocal and instrumental music

- Primarily a keyboard style

- Influenced by Duke Ellington (Afro-American fusion)

- Other instruments: piano, pedal organ, guitar/banjo, bass guitar, percussion and voice in a small instrumental ensemble

- Voice and piano have melodic role

- Songs often start with a brief introduction featuring the guitar or piano OR

Kwela

- Instrumental music mostly

- Guitar and banjo outline the chord progression and give rhythmic drive

- The guitar plays the skiffle-like rhythm

- Penny-whistle often used as lead instrument (saxophone added later)

- Songs usually start with a pennywhistle introduction

- Penny-whistle used as a warning signal during apartheid-era [5]

Any FIVE facts = 5 marks |

QUESTION 14

Abdullah Ibrahim

Melody

- Folk-like melodies

- Hymn-like/Chorale style

- Ghoema/Cape Malay characteristics

- Modal melodies

- Extensive improvisational style

- Melodies are often realised on the piano

Any FOUR correct facts = 4 marks |

Relevant example

- Mannenberg, Soweto is where it's at, Tsakwe (Royal Blue) [5]

Any correct example = 1 mark |

OR

Robbie Jansen

Melody

- Folk-like melodies

- Khoisan/Cape Malay melodies interwoven with Malaysian/Indonesian melismatic styles

- Saxophone melody produced with a nasal tone with vibrato at the end of phrases

- Lead-saxophone (alto) mostly plays the melody

- Extensive improvisation for all instruments, blending various styles (eclectic)

Any FOUR correct facts = 4 marks |

Relevant example

- Hoija Tjie Bonga, Tsakwe, Sommer Ghoema [5]

Any correct example = 1 mark |

OR

Winston Mankunku Ngozi

Melody

- Lead-saxophone (tenor) plays the melody

- Folk-like melodies

- Khoi-Khoi and San melodies intertwined

- Malaysian and Indonesian melismatic styles are fused

- Extensive improvisation for all instruments, blending various styles

- Call and response between lead saxophone and other instruments

Any FOUR correct facts = 4 marks |

Relevant example

- Abantwana be Afrika, Crossroads [5]

Any correct example = 1 mark |

QUESTION 15

Reasons for popularity:

- The very popular traditional Zulu Indlamu dance rhythms are prominently part of mbaqanga and that is the reason that it is popular. The modern style mbaqanga is based on the traditional music

- The music style mbaqanga is associated with the popular staple food, 'maize bread'

- A fusion of popular American jazz, mbube, kwela and marabi music caused more people to be drawn to this mixed style

- Introduction of Radio Bantu ensured that many musicians recorded their music for airplay

- The 'spirit of competition' around releasing new recordings made this style popular

- One of the reasons why it became popular is that it was an easy way for musicians to make a quick buck (money)

Any THREE reasons = 3 marks |

Style characteristics

- Use of both traditional and Western instruments

- Fuses traditional and Western music elements

- Electric guitar very important in mbaqanga, e.g. by Mahlathini and the Mahotella Queens

- Electronic organ more important in mbaqanga than in preceding styles of music, e.g. the Soul Brothers

- Sometimes a male-only vocal style: Soul Brothers

- Usually starts with a brief guitar introduction (or in the case of Soul Brothers, the introduction is done by the electronic organ)

- Heavy bass line and rock beat are prominent features

- Chord progression I – IV – V – I cycle over a bouncy 8/8 rhythm

- Music has a repetitive character

- Call and response used between the lead singer/guitarist and the backing singers/band

Any SEVEN style characteristics = 7 marks |

Artist/Band:

- Mahlathini and the Mahotella Queens

- Soul Brothers

- The Cool Crooners

- Makgona Tsohle Band

Any TWO artists/bands = 2 marks |

The essay will be marked according to the following criteria:

CRITERIA | MARK ALLOCATION | ||

Reasons for popularity | 1 mark for each correct fact | 3 | |

Style characteristics | 1 mark for each correct fact | 7 | |

Artists | 1 mark for each correct fact | 2 | |

Logical presentation and structure of the essay | Excellent | = 3 marks | 3 |

Good | = 2-2½ marks | ||

Average | = 1½ marks | ||

Below average | = 1 mark | ||

Weak | = ½ mark | ||

Not acceptable | = 0 marks | ||

TOTAL | 15 | ||

[15]

TOTAL SECTION D: 40

OR

SECTION E: INDIGENOUS AFRICAN MUSIC (IAM)

QUESTION 16

16.1

- vhaVenda drums

- Mbila mutondo

- Mbila dzamedza

- Ngoma

- Tshikona pipes (2)

Any TWO instruments = 2 marks |

16.2 Flute (1)

16.3

- Keyboard/organ

- Guitar

- Bass guitar

- Drum kit (1)

16.4 (3)

Any correct answer = 1 mark |

Indlamu | Mokhibo |

amaZulu dance | baSotho dance |

Fast and energetic | Can be moderate and calm |

Uses mostly the lower body and includes stomping of feet | Uses mostly the upper body and includes the shaking of the back and shoulders |

Performed, using feet | Performed while kneeling |

Any THREE correct correlated differences = 3 marks Candidates may answer in table format |

16.5 16.5.1 Ululation (1)

16.5.2 Izibongo (1)

16.5.3 Chordophone (1) [10]

QUESTION 17

- Traditional elements which were retained are the following:

- Kiba polyrhythms

- Always in Sepedi language

- Call and response between voices and instruments

- Ululation, crepitations and vocal lilting

- Changes which were introduced:

- Modern jazz rhythms are added

- Any modern instruments (guitar, keyboard, drum kit) can be used

- Any African language can be used

- Free kiba is recorded and sold for commercial gain. [5]

Any TWO facts relating to traditional elements = 2 marks Any THREE facts on transformation of elements to modern style = 3 marks | = 5 marks |

QUESTION 18

- He has created a modern version of the malombo style

- He employs various indigenous African languages

- He replaces the original reed flute with a Western flute

- Cyclical chord structures are employed

- Call and response between voice and instrument is used extensively ∙ Vocals, bass guitar, drum kit, indigenous drums and rattles are used [5]

Any FIVE correct facts = 5 marks |

QUESTION 19

- Ancestral worship

- Certain songs and dances exist exclusively to communicate with the ancestors e.g. at funerals and weddings

- Certain songs and dances induce a trance through which contact is established

- Through music and dance the assistance and blessing of the ancestors are sought e.g. during initiation ceremonies

- The participation of the community in the musical activity often signifies the joy of connecting with the ancestral spirits successfully

- Traditional Healers (Sangomas)

- Sangomas are agents and conduits of divinity, e.g. 'Saane' and 'Leepo'

- Sangomas will initiate the process of contacting the ancestral spirits by using invocative singing and praise poetry

- Sangomas will incite the community/people to participate in ceremony

- Singing, drums and whistles are employed during ritualistic performances to provide the link between the worshippers and the divine [5]

Any FIVE correct facts = 5 marks |

QUESTION 20

Playing techniques on guitar

- Ukuvamba technique:

- strumming chords percussively

- Ukupika technique:

- a finger-picking style

- the thumb plays the lower strings ('amadoda', the Zulu word for 'men')

- the other fingers in the right hand (mainly the index finger) plays a melody on the upper strings ('amatombazane', the Zulu word for 'women')

- A plectrum (called ikati) is often used

Any THREE correct facts = 3 marks |

Tuning of the guitar

- Different maskandi use different tunings depending on the specific style of dance/song

- Standard maskanda guitar tuning is called isiZulu-style

- strings are tuned as: EADGBD

- Isishameni-style

- strings are tuned as: DADABD

- Isichunu style

- strings are tuned as: DADABD (as in Isishameni)

- Isigeyane-style

- Uses isiZulu (standard maskanda tuning) but different rhythmic patterns

- Isimandolini style

- strings are tuned as: EBBC#F#G#

Any TWO correct facts = 2 marks |

Style of singing

- Based on amahubo (using the pentatonic scale)

- Umaskanda melody is an authentic remnant of the Zulu amahubo music, the foundation of all Zulu vocal music

- Range of voices is not wide: between a 5th and 11th

- Singers switch between singing and speaking

- Vocal glissandi or pitch bending is used

- Text for umaskanda music is in isiZulu

- Formal design of umaskanda music imitates the vocal style of isiZulu music which in turn is based on Zulu-speech

- Leader (call) and backup singers (response)

Any FIVE correct facts = 5 marks |

Izihlabo

- An instrumental introduction based on a descending motive played on guitar or concertina

- Consists of short bursting motifs

- It sounds like an 'improvised sound check' to check the tuning

- Uses free rhythm and metre

Any TWO correct facts = 2 marks |

The essay will be marked according to the following criteria:

CRITERIA | MARK ALLOCATION | ||

Playing techniques on the guitar | 1 mark for each correct fact | 3 | |

Tuning of guitar | 1 mark for each correct fact | 2 | |

Style of singing | 1 mark for each correct fact | 5 | |

Izihlabo | 1 mark for each correct fact | 2 | |

Logical presentation and structure of the essay | Excellent | = 3 marks | 3 |

Good | = 2-2½ marks | ||

Average | = 1½ marks | ||

Below average | = 1 mark | ||

Weak | = ½ mark | ||

Not acceptable | = 0 marks | ||

TOTAL | 15 | ||

[15]

TOTAL SECTION E: 40

GRAND TOTAL: 120

MECHANICAL TECHNOLOGY: AUTOMOTIVE GRADE 12 MEMORANDUM - NSC EXAMS PAST PAPERS AND MEMOS NOVEMBER 2018

MECHANICAL TECHNOLOGY: AUTOMOTIVE

GRADE 12

NSC EXAMS

PAST PAPERS AND MEMOS NOVEMBER 2018

MEMORANDUM

QUESTION 1: MULTIPLE-CHOICE QUESTIONS (GENERIC)

1.1 A ✔ (1)

1.2 C ✔ (1)

1.3 A ✔ (1)

1.4 B ✔ (1)

1.5 D ✔ (1)

1.6 A ✔ (1)

TOTAL QUESTION 1: [6]

QUESTION 2: SAFETY (GENERIC)

2.1 Angle grinder: (Before using)

- The safety guard must be in place before starting. ✔

- Protective shields must be placed around the object being grinded to protect the people around. ✔

- Use the correct grinding disc for the job. ✔

- Make sure that there are no cracks in the disc before you start. ✔

- Protective clothing and eye protection are essential. ✔

- Check electrical outlets and cord/plugs for any damages. ✔

- Ensure that lockable switch is disengaged. ✔

- Ensure that the disc and the nut are well secured. ✔

- Ensure that the removable handle is secured. ✔

- Remove all flammable material from the area. ✔

- Secure the work piece. ✔

- (Any 2 x 1) (2)

2.2 Welding goggles:

- To protect your eyes against sparks ✔

- To protect your eyes against heat ✔

- To be able to see where to weld ✔

- To protect your eyes from UV rays / bright light ✔

- To protect your eyes from smoke ✔

- (Any 2 x 1) (2)

2.3 PPE for Hydraulic press:

- Overall ✔

- Safety shoes ✔

- Safety goggle ✔

- Leather gloves ✔

- Leather apron ✔

- Face shield ✔

- (Any 2 x 1) (2)

2.4 Workshop layouts:

- Process layout ✔

- Product layout ✔ (2)

2.5 Employer’s responsibility regarding first-aid:

- Provision of first-aid equipment ✔

- First aid training ✔

- First-aid services by qualified personnel ✔

- Any first aid procedures ✔

- Display first aid safety signs ✔

- First aid personnel must be identified by means of arm bands or relevant personal signage ✔

- (Any 2 x 1) (2)

TOTAL QUESTION 2: [10]

QUESTION 3: MATERIALS (GENERIC)

3.1 Bending test:

- Ductility ✔✔

- Malleability ✔✔

- Brittleness ✔✔

- Flexibility ✔✔

- (Any 1 x 2) (2)

3.2 Heat-treatment:

3.2.1 Annealing:

- To relieve internal stresses ✔

- To soften the steel ✔

- To make the steel ductile ✔

- To refine the grain structure of the steel ✔

- To reduce the brittleness of the steel ✔

- (Any 2 x 1) (2)

3.2.2 Case hardening:

- To produce a wear resistant surface ✔ and it must be tough enough internally ✔ at the core to withstand the applied loads.

- Hard case ✔ and tough core. ✔

- (Any 1 x 2) (2)

3.3 Tempering process:

- To reduce ✔ the brittleness ✔ caused by the hardening process.

- Relieve ✔ strain ✔ caused during hardening process.

- Increase ✔ the toughness ✔ of the steel.

- (Any 1 x 2) (2)

3.4 Factors for heat-treatment processes:

- Heating temperature / Carbon content ✔

- Soaking (Time period at temperature) / Size of the work piece ✔

- Cooling rate / Quenching rate ✔ (3)

3.5 Hardening of steel:

- Steel is heated to 30 – 50°C above the higher critical temperature. (AC3) ✔

- It is then kept at that temperature to ensure (soaking) that the whole structure is Austenite. ✔

- The steel is then rapidly cooled by quenching it in clean water, brine or oil. ✔ (3)

TOTAL QUESTION 3: [14]

QUESTION 4: MULTIPLE-CHOICE QUESTIONS (SPECIFIC)

4.1 C ✔ (1)

4.2 B ✔ (1)

4.3 D ✔ (1)

4.4 D ✔ (1)

4.5 A ✔ (1)

4.6 C ✔ (1)

4.7 A ✔ (1)

4.8 D ✔ (1)

4.9 A / C ✔ (1)

4.10 A ✔ (1)

4.11 D ✔ (1)

4.12 D ✔ (1)

4.13 A ✔ (1)

4.14 A ✔ (1)

TOTAL QUESTION 4: [14]

QUESTION 5: TOOLS AND EQUIPMENT (SPECIFIC)

5.1 Equipment:

5.1.1 Compression tester ✔ (1)

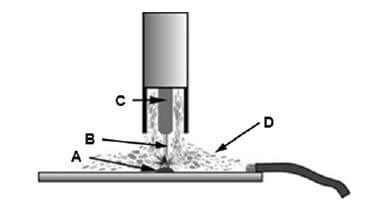

5.1.2

- A – Flexible piping / hose / tubing ✔

- B – Adaptor screw / Fitting / Attachment / Connector ✔

- C – Gauge ✔

- D – Pressure release valve ✔ (4)

5.1.3 Compression Tester:

- It measures the pressure created, ✔ when the piston is at top dead centre on power stroke. ✔ (2)

5.2 Cylinder leakage:

- To check whether the engine leaks gases ✔ from the cylinder during the compression stroke. ✔ (2)

5.3 Gas Analyser:

- To ensure ✔ an accurate reading. ✔

- o prevent ✔ a lean reading. ✔

- (Any 1 x 2 ) (2)

5.4 Function of a computerized diagnostic scanner:

- Scans all systems ✔ on the vehicle.

- Informs what adjustments can be made after diagnosis ✔

- (Any 1 x 1 ) (1)

5.5 Bubble gauge camber procedure:

- Mount the bubble gauge on to the straightened wheel ✔

- Zero the bubble gauge at the gauge zero scale ✔

- Take the reading on the camber scale ✔

- Do the same for the other wheel ✔ (4)

5.6 Dynamic balance on wheels:

- The plane of imbalance ✔

- The extent of the unbalancing forces ✔

- The sense of direction of these forces (clockwise or counter clockwise) ✔

- Determine the location of weight placement ✔

- Magnitude of the weights ✔

- The run-out of the tyre and wheel assembly ✔

- (Any 3 x 1 ) (3)

5.7 Purpose of turn tables:

- To make it possible to turn ✔ the front wheels in or out ✔ to check ✔ the wheel angles. ✔ (4)

TOTAL QUESTION 5: [23]

QUESTION 6: ENGINES (SPECIFIC)

6.1 Static balancing of the crankshaft:

- The crankshaft is in static when the mass in all directions ✔ from the centre of rotation is equal while it is at rest. ✔ (2)

6.2 Cylinder layouts:

6.2.1 V - engine layout ✔ (1)

6.2.2 In line (straight) engine layout ✔ (1)

6.3 Firing order in an engine:

- By removing the tappet cover and determining which are intake valves and which are exhaust valves ✔

- Rotating the engine in the direction in which it turns. ✔

- Watch the order in which one set of valves, inlet or exhaust operates ✔

- This will give the order in which the inlet stroke or exhaust stroke occurs ✔

- The power strokes occur in the same order ✔

OR - Cylinder 1 must be at TDC on power stroke ✔

- Remove the distributor cap ✔

- Ensure to turn the engine in the correct direction of rotation ✔

- Determine the direction of rotation of the rotor ✔

- Trace the firing order by the HT leads ✔

- (Any 1 x 5 ) (5)

6.4 Firing order of engines:

6.4.1 Four cylinder in-line engine:

- 1,3,4,2; or ✔

- 1,2,4,3 ✔

- (Any 1 x 1 ) (1)

6.4.2 V6-cylinder engine:

- 1,4,2,5,3,6 ✔

- 1,2,3,4,5,6 ✔

- 1,6,5,4,3,2 ✔

- 1,4,5,6,3,2 ✔

- (Any 1 x 1 ) (1)

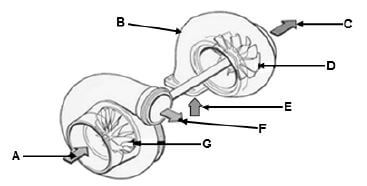

6.5 Turbo charger:

6.5.1 Turbocharger:

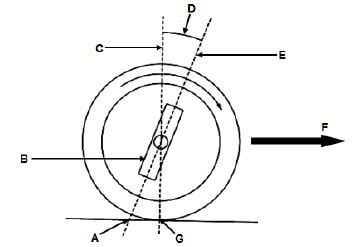

- A – Compressor air inlet ✔

- B – Turbine housing ✔

- C – Turbine exhaust gas outlet ✔

- D – Turbine wheel ✔

- E – Turbine exhaust gas inlet ✔

- F – Compressed air outlet ✔

- G – Compressor wheel ✔ (7)

6.5.2 Turbocharger advantages:

- More power / speed / boost is obtained from an engine with the same capacity ✔

- There is no power loss as the turbocharger is driven by exhaust gasses ✔

- Improved fuel consumption ✔

- The effect of height above sea level is eliminated ✔

- Generally, cheaper than superchargers ✔

- Any ( 2 x 1) (2)

6.6 Terminology:

6.6.1 Boost:

- Refers to the increase in manifold pressure ✔ that is generated by the turbocharger in the intake that exceeds the normal atmospheric pressure. ✔ (2)

6.6.2 Turbo lag:

- It is a delay ✔ between pushing on the accelerator and feeling turbo kick in. ✔ or

- The time ✔ it takes the turbo charger to reach operating speed. ✔

- (Any 1 x 2) (2)

6.7 Purpose of waste gate:

- It diverts exhaust gases ✔ away from the turbine wheel to regulate the turbine speed ✔ and consequently boost pressure. (2)

6.8 Oil cooler:

- To cool (prevent overheating) the oil ✔ that lubricates the turbocharger bearings and shaft. ✔ (2)

TOTAL QUESTION 6: [28]

QUESTION 7: FORCES (SPECIFIC)

7.1 Torque:

- Torque is the twisting effort ✔ transmitted by a rotating shaft or wheel. ✔

- Turning force applied ✔ over a centre of a round object. ✔

- (Any 1 x 2) (2)

7.2 Clearance volume:

- This is the volume of the space ✔ above the crown of the piston at TDC. ✔ (2)

7.3 Method to increase compression ratio:

Remove shims between the cylinder block and cylinder head. ✔

- Fit thinner cylinder head gasket. ✔

- Machine metal from cylinder head. ✔

- Skim metal from cylinder block. ✔

- Fit a piston with a higher crown. ✔

- Fit a crankshaft with a longer stroke. ✔

- Increase the bore of the cylinders. / bigger pistons. ✔

- (Any 2 x 1) (2)

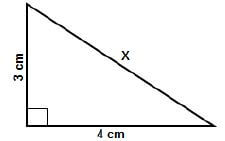

7.4 Calculation of compression ratio:

7.4.1

- Swept Volume = πD2 × L ✔

4

= π (7,5)2 8,0 ✔

4

353,43 cm3 ✔ (3)

7.4.2

- Compression Ratio = SV + CV

CV

CV = SV

CR - 1

= 353,43

8,5 1

= 353,43

7,5

= 47,12 cm ✔ (3)

7.4.3 New compression ratio:

- Sweptvolume = πD2 × L

4

= π7,82 × 8

4

= 382,27 cm ✔ - New compression Ratio = SV + 1

CV

= 382,27 + 1

47,12

= 8,11 + 1:1

= 9.11:1

OR - New compression Ratio = SV + CV

CV

= 382.27 + 47.12

47.12

= 9.11:1 ✔(6)

7.5 Calculations: Power:

7.5.1 IndicatedPower = P × L × A × N × n

- P = 1400 kPa

L = 110

1000

= 0,11 m - A = πD2

4

= π0,102

4

= 7,85 x 10-3m2 ✔ ✔ - N = 3600

60 × 2

= 30 r/s ✔ ✔

n 4 cylinders - IndicatedPower = P × L × A × N × n

= [1400 × 103] × 0,11 × [7,85 × 10-3] × 30 × 4

= 145068 W

= 145,07 kW (8)

7.5.2 T = F × r

- (75 × 10) × 0,45

= 337,5N.m ✔ - Brake power = 2π × N × T

= 2π × 60 × 337,5 ✔

= 127234,5 W

= 127,23 kW ✔ (4)

7.5.3 Mechanicalefficiency = BP 100%

IP

- = 127,23 × 100%

145,07 00 %

= 87,70% ✔ (2)

TOTAL QUESTION 7: [32]

QUESTION 8: MAINTENANCE (SPECIFIC)

8.1 Gas analyser:

- Exhaust gasses ✔

- CO gasses ✔

- CO2 gasses ✔

- SO2 gasses ✔

- NOx gasses ✔

- HC gasses ✔

- O2 gasses ✔

- (Any 1 x 1) (1)

8.2 Specification for gas analysis:

- % Hydrocarbon / HC ✔

- % Carbon monoxide / CO ✔

- % Carbon dioxide / CO2 ✔

- % Nitrogen oxide / NOx ✔

- % Sulphur dioxide / SO2 ✔

- (Any 3 x 1) (3)

8.3 Cylinder leakage test: (Results)

- Hissing noise at air intake ✔

- Hissing noise at exhaust pipe ✔

- Hissing noise in dipstick hole ✔

- Hissing noise under tappet cover ✔

- Bubbles in radiator water ✔

- Hissing noise at adjacent cylinders ✔

- (Any 2 x 1) (2)

8.4 Cylinder Leakage test: (Causes)

- Worn cylinders ✔

- Worn piston ✔

- Worn piston rings ✔

- Leaking inlet valve ✔

- Leaking exhaust valve ✔

- Leaking cylinder head gasket ✔

- Cracked cylinder head / block ✔

- (Any 2 x 1) (2)

8.5 Compression test procedures:

- Get the engine to normal operating temperature. ✔

- Disconnect the fuel supply and ignition system. ✔

- Remove spark plugs. ✔

- Fit the compression tester ✔

- Depress the throttle and crank the engine a few revolutions. ✔

- Record and compare the pressure reading for each cylinder with manufacturers specifications. ✔ (6)

8.6 Reasons for low oil pressure:

- Worn oil pump ✔

- Blocked oil pump screen/filter/strainer in the sump ✔

- Worn main, big-end and camshaft bearings ✔

- Blocked or restricted oil filter ✔

- Dirty or contaminated oil ✔

- Oil leaks ✔

- Too little oil in engine ✔

- Incorrect grade (viscosity) of oil ✔

- Pressure relief valve spring too weak or damaged ✔

- Plunger / Ball stuck in open position ✔

- Dirt stuck between ball and seat ✔

- (Any 2 x 1) (2)

8.7 Cooling system pressure test:

- Start engine and allow to heat up. Fit radiator pressure tester to radiator. ✔

- Pressurize the cooling system according to manufacture’s specification. ✔

- Watch the pressure for a while, if it drops there is a leak. ✔

- Make a visual check for leaks. ✔

- Install radiator cap to tester and pump tester, the cap should release air at its rated pressure. ✔

- Check the rubber seal for cracks and damage. ✔

- Check the vacuum valve for free movement and operation. ✔ (7)

TOTAL QUESTION 8: [23]

QUESTION 9: SYSTEMS AND CONTROL (AUTOMATIC GEARBOX) (SPECIFIC)

9.1 Differences between an automatic and manual gearbox:

- There is no clutch pedal in a motor vehicle with an automatic gearbox. / There is a clutch pedal in a motor vehicle with a manual gearbox. ✔

- There is no need to change gears, the shifting of the gears happens automatically. ✔

- Automatic transmission uses thin oil while manual gearbox uses thicker oil. ✔

- Automatic transmission uses torque converter while manual gearbox uses clutch assembly. ✔

- (Any 2 x 1) (2)

9.2 Advantages of automatic gearbox:

- It reduces driver fatigue ✔

- It ensures great reduction of wheel spin under bad road conditions ✔

- The vehicle can be stopped suddenly without the engine stalling ✔

- The system dampens all engine torsional vibrations ✔

- Easier to drive (e.g. Disabled person with one leg) ✔

- (Any 2 x 1) (2)

9.3 Torque converter:

9.3.1 Torque converter function:

- Transfers engine torque to the transmission. ✔

- It multiplies the engine torque to the transmission. ✔

- Provides a direct-drive, or mechanical link from the engine to the transmission. ✔

- The torque converter dampens all engine torsional vibrations. ✔

- The torque converter acts as a flywheel. ✔

- (Any 2 x 1) (2)

9.3.2 Parts:

- A – One-way clutch / Turbine ✔

- B – Turbine / Impeller ✔

- C – Pump ✔

- D – Turbine shaft ✔

- E – Gearbox housing ✔ (5)

9.4 Single epicyclic gear train:

- Overdrive forward ✔

- Overdrive reverse ✔

- Gear reduction forward ✔

- Gear reduction reverse ✔

- Direct drive ✔

- Neutral ✔

- (Any 5 x 1) (5)

9.5 Purpose of gear ratio in the gearbox:

- It is used in order to utilise the usable torque ✔ developed in a relatively limited speed range of the engine over a greater road speed range. ✔

- Allows different speeds ✔ depending on the different loads. ✔

- (Any 1 x 2) (2)

TOTAL QUESTION 9: [18]

QUESTION 10: SYSTEMS AND CONTROL (AXLES, STEERING GEOMETRY AND ELECTRONICS) (SPECIFIC)

10.1 Preliminary wheel alignment checks:

- Kerb mass (tank full of petrol, spare wheel and tools) against the manufacturer’s specifications. ✔

- Uneven wear on the tyre. ✔

- Tyre pressure. ✔

- Run-out on the wheels; check wheel nuts with torque wrench. ✔

- Correct preload on the wheel (hub) bearings. ✔

- Kingpins and bushes. ✔

- Suspension ball joints for wear, locking and lifting. ✔

- Suspension bushes for excessive free movement. ✔

- Steering box play and whether secure on chassis. ✔

- Tie-rod ends. ✔

- Sagged springs, this includes riding height. ✔

- Ineffective shock absorbers. ✔

- Spring U-bolts. ✔

- Chassis for possible cracks and loose cross-members. ✔

- Wheels must be balanced ✔

- Wheel alignment specifications ✔

- Drive shafts / CV-joints ✔

- (Any 5 x 1) (5)

10.2 Caster

10.2.1 Negative ✔ Caster ✔ (2)

10.2.2 Parts:

- A – Contact point of king pin centre line ✔

- B – King pin ✔

- C – Perpendicular line / vertical line / normal line ✔

- D – Negative caster angle ✔

- E – Centre line of king pin ✔

- F – Front of vehicle / Direction of wheel motion ✔

- G – Point of wheel contact / Wheel ✔ (7)

10.2.3 Negative caster angle is the forward tilt ✔ of the kingpin at the top, ✔ viewed from the side. ✔ (3)

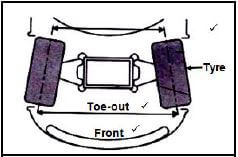

10.3 Toe-out:  (3)

(3)

10.4 Purpose of the king pin inclination:

- To bring the front wheels back to the straight-ahead position ✔ after rounding a corner without any driver effort. ✔

- Reduce ✔ the scrub radius. ✔

- (Any 1 x 2) (2)

10.5 Catalytic converter:

- Oxidation ✔

- Reduction ✔

- (Any 1 x 1) (1)

10.6 Purpose of the speed control system:

- The purpose of the speed control system is to control the throttle opening ✔ and to keep the vehicle speed constant. ✔ (2)

10.7 Advantage of speed control:

- Driver fatigue is reduced. ✔

- The set speed is controlled constantly. ✔

- Improved fuel consumption. ✔

- A consistently controlled speed helps to prevent speeding fines. ✔

- (Any 2 x 1) (2)

10.8 Fuel pressure regulator:

- Fuel pressure regulator regulates the fuel pressure in relation to the manifold pressure. ✔ (1)

10.9 Output frequency of an alternator:

- Increase the turns of wire on the stationary coil. ✔

- Increase the magnetic fields. ✔

- Increase the rotational frequency at which the magnet rotates. ✔

- (Any 2 x 1) (2)

10.10 Stator and stator windings:

- To provide a core which concentrates the magnetic lines of force onto the stator windings ✔

- To provide a coil into which a voltage is induced which is used to charge the battery. ✔

- (Any 1 x 1) (1)

10.11 Function of rotor assembly:

- Is to provide a rotating electro-magnet. ✔ (1)

TOTAL QUESTION 10: [32]

TOTAL: 200d

MECHANICAL TECHNOLOGY: FITTING AND MACHINING GRADE 12 MEMORANDUM - NSC EXAMS PAST PAPERS AND MEMOS NOVEMBER 2018

MECHANICAL TECHNOLOGY: FITTING AND MACHINING

GRADE 12

NSC EXAMS

PAST PAPERS AND MEMOS NOVEMBER 2018

MEMORANDUM

QUESTION 1: MULTIPLE-CHOICE QUESTIONS (GENERIC)

1.1 A ✔ (1)

1.2 C ✔ (1)

1.3 A ✔ (1)

1.4 B ✔ (1)

1.5 D ✔ (1)

1.6 A ✔ (1)

TOTAL QUESTION 1: [6]

QUESTION 2: SAFETY (GENERIC)

2.1 Angle grinder: (Before using)

- The safety guard must be in place before starting. ✔

- Protective shields must be placed around the object being grinded to protect the people around. ✔

- Use the correct grinding disc for the job. ✔

- Make sure that there are no cracks in the disc before you start. ✔

- Protective clothing and eye protection are essential. ✔

- Check electrical outlets and cord/plugs for any damages. ✔

- Ensure that lockable switch is disengaged. ✔

- Ensure that the disc and the nut are well secured. ✔

- Ensure that the removable handle is secured. ✔

- (Any 2 x 1) (2)

2.2 Welding goggles:

- To protect your eyes against sparks ✔

- To protect your eyes against heat ✔

- To be able to see where to weld ✔

- To protect your eyes from UV rays ✔

- (Any 2 x 1) (2)

2.3 PPE for Hydraulic Press:

- Overall ✔

- Safety shoes / boots✔

- Safety goggle ✔

- Leather gloves ✔

- Face shield ✔

- (Any 2 x 1) (2)

2.4 Workshop layouts:

- Process layout ✔

- Product layout ✔ (2)

2.5 Employer’s responsibility regarding first-aid:

- Provision of first-aid equipment ✔

- First aid training ✔

- First-aid services by qualified personnel ✔

- Any first aid procedures / treatment ✔

- Display first aid safety signs ✔

- First aid personnel must be identified by means of arm bands or relevant personal signage ✔

- (Any 2 x 1) (2)

TOTAL QUESTION 2: [10]

QUESTION 3: MATERIALS (GENERIC)

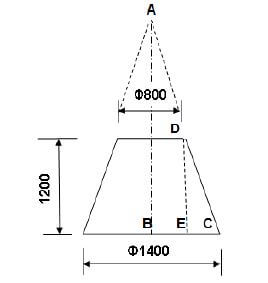

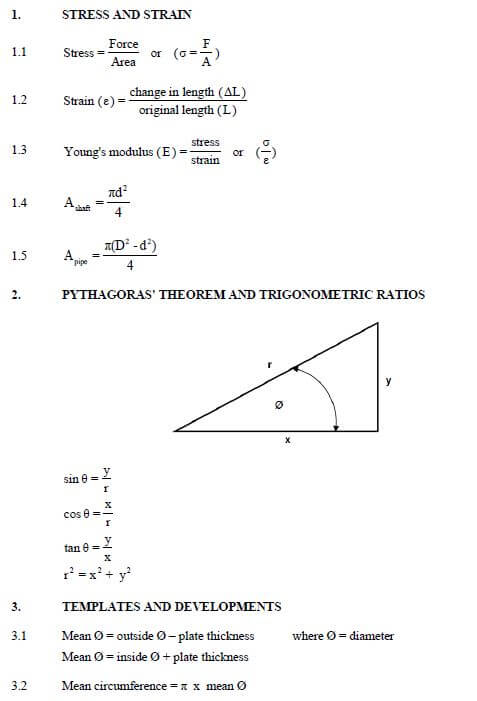

3.1 Bending test:

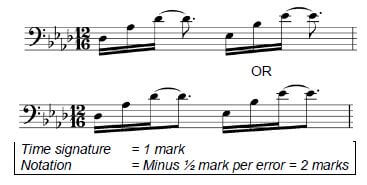

- Ductility ✔✔

- Malleability ✔✔

- Brittleness ✔✔

- Flexibility ✔✔

- (Any 1 x 2) (2)

3.2 Heat-treatment:

3.2.1 Annealing:

- To relieve internal stresses ✔

- To soften the steel ✔

- To make the steel ductile ✔

- To refine the grain structure of the steel ✔

- To reduce the brittleness of the steel ✔

- (Any 2 x 1) (2)

3.2.2 Case hardening:

- To require a wear resistant surface ✔ and it must be tough enough internally ✔ at the core to withstand the applied loads.

- Hard case ✔ and tough core. ✔

- (Any 1 x 2) (2)

3.3 Tempering process:

- To reduce ✔ the brittleness ✔ caused by the hardening process.

- Relieve ✔ strain ✔ caused during hardening process.

- Increase ✔ the toughness of the steel. ✔

- (Any 1 x 2) (2)

3.4 Factors for heat-treatment processes:

- Heating temperature / Carbon content ✔

- Soaking (Time period at temperature) / Size of the work piece ✔

- Cooling rate / Quenching rate ✔ (3)

3.5 Hardening of steel:

- Steel is heated to 30 – 50°C above the higher critical temperature. (AC3) ✔

- It is then kept at that temperature to ensure (soaking) that the whole structure is Austenite. ✔

- The steel is then rapidly cooled by quenching it in clean water, brine or oil. ✔ (3)

TOTAL QUESTION 3: [14]

QUESTION 4: MULTIPLE-CHOICE QUESTIONS (SPECIFIC)

4.1 C ✔ (1)

4.2 A ✔ (1)

4.3 D ✔ (1)

4.4 A ✔ (1)

4.5 B ✔ (1)

4.6 A ✔ (1)

4.7 B ✔ (1)

4.8 B ✔ (1)

4.9 D ✔ (1)

4.10 C ✔ (1)

4.11 B ✔ (1)

4.12 D ✔ (1)

4.13 D ✔ (1)

4.14 C ✔ (1)

TOTAL QUESTION 4: [14]

QUESTION 5: TERMINOLOGY (LATHE AND MILLING MACHINE) (SPECIFIC)

5.1 Advantages of using the tailstock to cut an external taper:

- Long an accurate taper can be cut. ✔

- The automatic feed can be used which result in a good finish. ✔ (2)

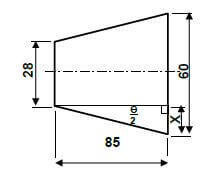

5.2 Calculate the compound slide set-over:

- Tan θ = D - d

2 2L

Tan θ = 60 - 28

2 2 × 85

= 0,188 ✔ ✔

θ = 10,66 º

2

OR

- X = D - d

2

= 60 - 28

2

= 16 mm - Tan θ = 16

2 85

θ = 10,66 º (5)

2

5.3 Centre gauge:

- To measure the form and angle of the screw cutting tool angle while grinding the tool ✔

- To set the screw cutting tool square/perpendicular to the axis of the work piece ✔ (2)

5.4 Parallel key:

Length:

- Length = 1,5 × diameter

= 1,5 × 42 ✔ ✔

= 63 mm ✔ (3)

5.5 Advantages of up-cut milling:

- Deeper cuts can be made as the cutting pressure on the cutter is lower than down cut milling. ✔

- The process enables hard steel to be cut, because the total cutting pressure is absorbed by the material at the back of the edge. ✔

- Metal with hard scale, such as castings or forgings, the cut is started under the scale where the material is softer which extends the life of the cutter. ✔

- A quicker/course feed can be used. ✔

- The strain on the cutter and arbour will be less. ✔

- Vibration is limited ✔

- Good finish ✔

- Low noise level ✔

- (Any 2 x 1) (2)

5.6 Disadvantage of down-cut milling:

- Vibration in the arbour is unavoidable. ✔

- A fine feed must be used. ✔

- When milling a material with hard scale the milling cutter will be damaged. ✔

- Process takes time because of slower feed. ✔

- Noisy process. ✔

- Bad finish because of vibration. ✔

- (Any 2 x 1) (2)

5.7 Methods of centring a milling cutter:

- Square and ruler method. ✔

- Set-over method by milling machine dial. ✔

- Dial indicator method ✔

- Using reference points on digital read out equipment ✔

- (Any 2 x 1) (2)

TOTAL QUESTION 5: [18]

QUESTION 6: TERMINOLOGY (INDEXING) (SPECIFIC)

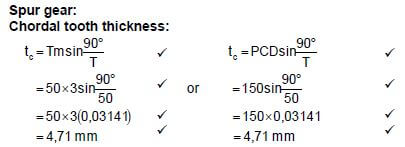

6.1 Spur gear:

Chordal tooth thickness:  (4)

(4)

6.2 Calculate simple indexing:

- Simple Indexing = 40

N

= 40

13

= 3 1

13

= 3 1 × 3

13 3 - = 3 3

39

3 full turns and 3 holes in a 39 hole circle (4)

6.3 Differential indexing:

6.3.1 Indexing required:

- Indexing = 40 = 40

n 127

= 40 = 40 ÷ 5

A 125 5

= 8

25

Indexing 8 holes on the 25 hole circle (3)

6.3.2 Change gears required:

- Dr = A-n × 40

Dn A 1

= 125 - 127 × 40

125 1

= 2 × 40

125 1

= -80 ÷ 5

125 5

= -16 × 4

25 4

= -64

100 (5)

6.3.3 Direction of rotation of index plate:

- The index plate will turn the opposite ✔ direction as the index crank handle. (1)

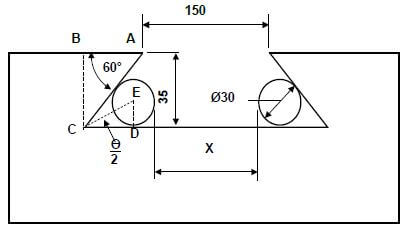

6.4 Calculate distance “x” between rollers:

- "x"=150 +2(AB)− 2(CD)− 2r

tanθ = BC

AB

AB = BC

tanθ

= 35

tan 60º

= 20,207 mm

= 20,21 mm - tanθ = DE

CD

CD = 15

tanθ

CD = 15

tan30º

= 25,98 mm

- " x" = 150 + 2(AB) - 2(CD) - 2r

= 150 + 2 (20,21) - 2 (25,98) - 2 (15)

= 150 + 40,42 - 51,96 - 30

= 108,454m m

= 108,45 m m ✔ (9)

6.5 Reasons for balancing work piece on a centre lathe:

- Prevent unnecessary bearing loads ✔

- Prevent excessive vibration ✔

- To obtain a good finish ✔

- To prevent clatter on the gear teeth ✔

- To prevent the spindle from bending ✔

- (Any 2 x 1) (2)

TOTAL QUESTION 6: [28]

QUESTION 7: TOOLS AND EQUIPMENT (SPECIFIC)

7.1 Hardness testers:

- Brinell-hardness tester ✔

- Rockwell-hardness tester ✔

- Vickers ✔

- (Any 2 x 1) (2)

7.2 Moment tester:

- To determine the reactions ✔ on either side of a simply loaded beam. ✔ (2)

7.3 Tensile test:

- A piece of material is subjected to an increasing axial load ✔ while measuring ✔ the corresponding elongation ✔ of the material. (3)

7.4 Depth micro-meter:

- Reading = 100 + 11,00 + 0,50 + 0,09 ✔

= 111,59 mm (5)

7.5 Measure depth:

- Vernier calliper ✔ (1)

TOTAL QUESTION 7: [13]

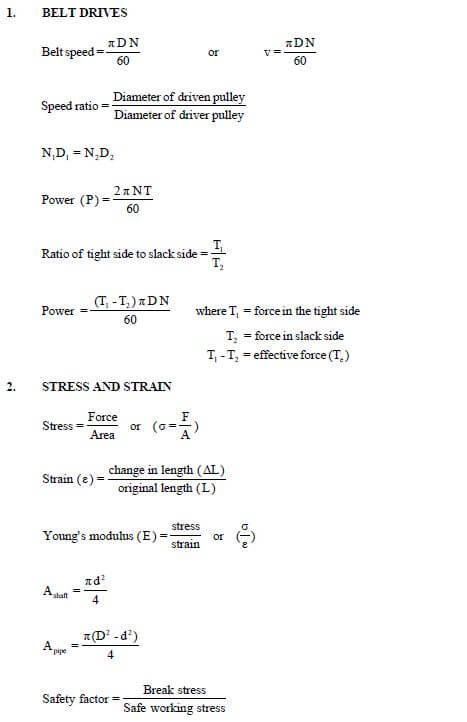

QUESTION 8: FORCES (SPECIFIC)

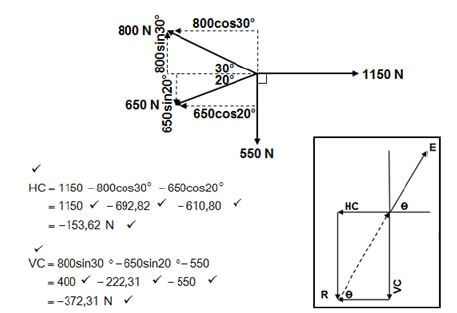

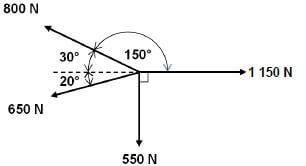

8.1 Forces:  (15)

(15)

Horizontal Components | Magnitudes | Vertical Components | Magnitudes |

1150cos0° | 1150N | 1150sin0° | 0N |

800cos150° | -692,82N | 800sin150° | 400N |

650cos200° | -610,80N | 650sin200° | -222,31N |

550cos270° | 0N | 550sin270° | -550N |

TOTAL: | -153,62N | TOTAL: | -372,31N |

- E2 = HC2 + VC2

√E2 = √(53,62 + 372,312)

E = 402,76N

Tanθ = VC

HC

= 372.31

153,62

θ = 67,58º

Equilibrant = 402,76N en 67,58º North from East (15)

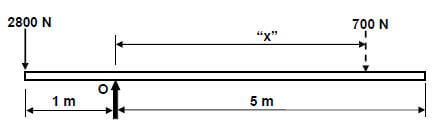

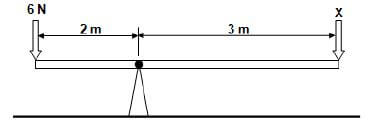

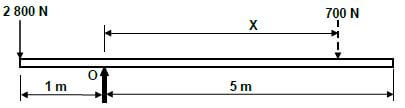

8.2 Moments:

Calculate “x”:

Take moments about O.

- ∑RHM = ∑LHM

700 × "x" 2800 × 1

700 × "x" 2800

"×" = 2800

700

"x" = 4m ✔ ✔ (4)

8.3 Stress and Strain:

8.3.1 Type of stress:

- Compressive stress ✔ (1)

8.3.2 Stress:

- A = π(D2 -d2)

4

= π(0,042 - 0,032)

4

= A = 0,55 × 10σ m2

σ = F

A

= 50 × 10σ

0,55 ×10σ

σ = 90,91 × 10σ Pa

σ = 90,91 MPa ✔

(NO UNIT – NO MARK) (5)

8.3.3 Change in length:

- E = σ

ε

ε = σ

E

= 90,91 × 106 ✔

90 × 109

= 1,01 × 10-3 ✔

(IF ANY UNIT IS GIVEN – NO MARK)

- ε = ΔL

L

ΔL = ε × L

= (1,01 × 10-3) × 80

= 0,08 mm ✔ (5)

8.3.4 Safety factor:

- Safety factor = Break stress

Safe workingstress

Safe workingstress = Break stress

Safety factor

= 600 × 106

4

= 150 × 106 Pa

= 150 MPa ✔(3)

TOTAL QUESTION 8: [33]

QUESTION 9: MAINTENANCE (SPECIFIC)

9.1 Lack of preventative maintenance:

- Risk of injury or death. ✔

- Financial loss due to damage suffered as a result of part failure and the waste of material. ✔

- Loss of valuable production time. ✔ (3)

9.2 Causes for the malfunctioning of chain drive systems:

- Lack of or incorrect lubrication ✔

- Lack of maintenance ✔

- Overloading ✔

- Misalignment of sprockets ✔

- Incorrect chain tension ✔

- Contamination of chain drive system such as dust or sand ✔

- (Any 2 x 1) (2)

9.3 Procedures to reduce the physical wear on a belt drive system:

- Check the belt alignment. ✔

- Checking the belt tension. ✔

- Prevent overloading of the system. ✔

- Keep the pulleys and belt clean. ✔

- Check that all covers are secure. ✔

- (Any 2 x 1) (2)

9.4 Procedures to replace the belt on a belt drive system:

- Ensure that the machine is switched off ✔

- Release the tension on the belt ✔

- Remove the belt from the pulleys ✔

- Fit the correct size replacement belt onto the pulleys ✔

- Check the pulley alignment ✔

- Apply adequate tension according to specification and lock the system ✔

- (Any 5 x 1) (5)

9.5 Properties of materials:

9.5.1 Poly vinyl chloride (PVC):

- Flexible ✔

- Rubber-like substance ✔

- Makes a dull sound when dropped ✔

- Tough ✔

- Act as an insulator ✔

- It is durable ✔

- Highly resistant to oxidative material ✔

- Oil, water and chemical resistant ✔

- (Any 1 x 1) (1)

9.5.2 Carbon fibre:

- Strong ✔

- Tough ✔

- Light weight ✔

- Good electrical conductor ✔

- (Any 1 x 1) (1)

9.6 Difference between “Thermoplastic” and “Thermo hardened (thermosetting)” composites:

- Thermoplastics can be reheated and deformed. / Recyclable ✔

- Thermo hardened cannot be reheated. / Non-recyclable ✔ (2)

9.7 Examples of thermo hardened composites:

- Carbon fibre or (Any application) ✔

- Glass fibre or (Any application) ✔

- Bakelite or (Any application) ✔

- Teflon or (Any application) ✔

- (Any 2 x 1) (2)

TOTAL QUESTION 9: [18]

QUESTION 10: JOINING METHODS (SPECIFIC)

10.1 Square thread:

10.1.1 The lead of the thread:

- Lead = pitch × no of starts

= 5 × 2 ✔

= 10 mm ✔ (2)

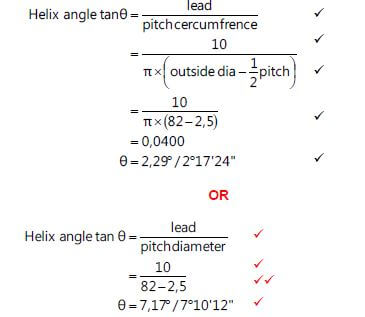

10.1.2 The helix angle of the thread:  (5)

(5)

10.1.3 The leading tool angle:

- Leadingtoolangle 90º helix angle + clearanceangle

= 90º - (2,29º + 3º)

= 84,71º /84º 42'36"

OR - Leadingtoolangle 90º helix angle + clearanceangle

= 90º - (7,17º + 3º)

79,83º / 79º 49'48" (2)

10.1.4 The following tool angle:

- Followingtoolangle = 90º + (helix angle - clearanceangle)

= 90º + (2,29º - 3º)

= 89,29º /89º 17'24"

OR - Following toolangle = 90º + (helix angle - clearanceangle)

= 90º + ( 7,17º - 3º)

= 94,17º / 94º 10'12" (2)

10.2 Measurements of a screw thread :

10.2.1 Metric screw thread ✔ (1)

10.2.2 Crest / Major / External / Basic / Nominal / Outside diameter ✔ (1)

10.2.3 Pitch ✔ (1)

10.3 Angles of a square thread cutting tool:

- A – Helix angle ✔

- B – Clearance angle ✔

- C – Leading tool angle ✔

- D – Following tool angle ✔ (4)

TOTAL QUESTION 10: [18]

QUESTION 11: SYSTEMS AND CONTROL (DRIVE SYSTEMS) (SPECIFIC)

11.1 Advantages of a belt drive system compared to a chain drive system:

- Silent operation ✔

- Less expensive ✔

- Drive can take place over a longer distance ✔

- No lubrication needed ✔

- (Any 2 x 1) (2)

11.2 Hydraulics:

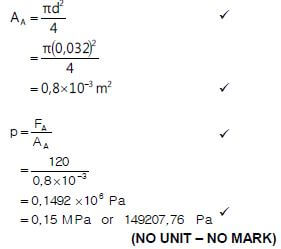

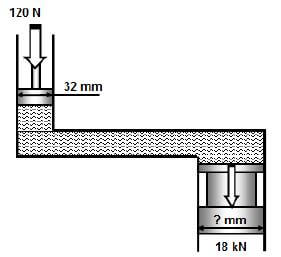

11.2.1 Fluid pressure:  (4)

(4)

11.2.2 Diameter of the ram:  (6)

(6)

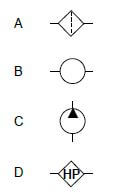

11.3 Hydraulic symbols: One-way valve  (1)

(1)

11.4 Belt drives:

Rotation frequency of the drive pulley:

- NDRDDR = NDNDDN

NDR = NDN × DDN

DDR

= 80 × 240

75

= 256 r/min ✔ ✔ ✔ (4)

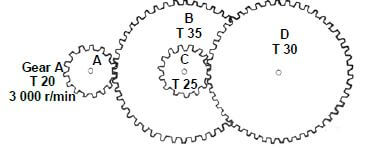

11.5 Gear drives:

11.5.1 Rotation frequency of the output:

- NA = Product of Driven gears

ND Product of Driver gears

ND = TA × TC

NA TB × TD

ND = TA × TC × NA

TB × TD

= 20 × 25 × 3000

35 × 30

ND = 1428,57 r/min

60

= 23,81 r/sec ✔

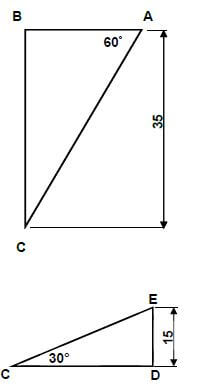

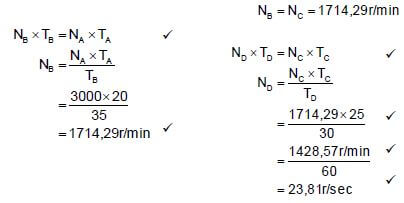

OR  (6)

(6)

11.5.2 Gear ratio:

- Gear ratio = Product of the number of teeth on driven gears✔

Product of the number of teeth on driver gears

=35 × 30

20 25

= 2,1 : 1 (3)

11.6 Work done:

- Work done F × s

= 250 × 15

= 3750 Jouleor N.m ✔(2)

TOTAL QUESTION 11: [28]

TOTAL: 200

MECHANICAL TECHNOLOGY: WELDING AND METALWORK GRADE 12 MEMORANDUM - NSC EXAMS PAST PAPERS AND MEMOS NOVEMBER 2018

MECHANICAL TECHNOLOGY: WELDING AND METALWORK

GRADE 12

NSC EXAMS

PAST PAPERS AND MEMOS NOVEMBER 2018

MEMORANDUM

QUESTION 1: MULTIPLE-CHOICE QUESTIONS (GENERIC)

1.1 A ✔ (1)

1.2 C ✔ (1)

1.3 A ✔ (1)

1.4 B ✔ (1)

1.5 D ✔ (1)

1.6 A ✔ (1)

TOTAL QUESTION 1: [6]

QUESTION 2: SAFETY (GENERIC)

2.1 Angle grinder: (Before using)

- The safety guard must be in place before starting. ✔

- Protective shields must be placed around the object being grinded to protect the people around. ✔

- Use the correct grinding disc for the job. ✔

- Make sure that there are no cracks in the disc before you start. ✔

- Protective clothing and eye protection are essential. ✔

- Check electrical outlets and cord/plugs for any damages. ✔

- Ensure that lockable switch is disengaged. ✔

- Ensure that the disc and the nut are well secured. ✔

- Ensure that the removable handle is secured. ✔

- Remove all flammable material from the area. ✔

- Secure the work piece. ✔

- (Any 2 x 1) (2)

2.2 Welding goggles:

- To protect your eyes against sparks ✔

- To protect your eyes against heat ✔

- To be able to see where to weld ✔

- To protect your eyes from UV rays / bright light ✔

- To protect your eyes from smoke ✔

- (Any 2 x 1) (2)

2.3 PPE for Hydraulic press:

- Overall ✔

- Safety shoes ✔

- Safety goggle ✔

- Leather gloves ✔

- Leather apron ✔

- Face shield ✔

- (Any 2 x 1) (2)

2.4 Workshop layouts:

- Process layout ✔

- Product layout ✔ (2)

2.5 Employer’s responsibility regarding first-aid:

- Provision of first-aid equipment ✔

- First aid training ✔

- First-aid services by qualified personnel ✔

- ∙ Any first aid procedures ✔

- Display first aid safety signs ✔

- First aid personnel must be identified by means of arm bands or relevant personal signage ✔

- Any 2 x 1) (2)

TOTAL QUESTION 2: [10]

QUESTION 3: MATERIALS (GENERIC)

3.1 Bending test:

- Ductility ✔✔

- Malleability ✔✔

- Brittleness ✔✔

- Flexibility ✔✔

- Any 1 x 2) (2)

3.2 Heat-treatment:

3.2.1 Annealing:

- To relieve internal stresses ✔

- To soften the steel ✔

- To make the steel ductile ✔

- To refine the grain structure of the steel ✔

- To reduce the brittleness of the steel ✔

- (Any 2 x 1) (2)

3.2.2 Case hardening:

- To produce a wear resistant surface ✔ and it must be tough enough internally ✔ at the core to withstand the applied loads.

- Hard case ✔ and tough core. ✔

- (Any 1 x 2) (2)

3.3 Tempering process:

- To reduce ✔ the brittleness ✔ caused by the hardening process.

- Relieve ✔ strain ✔ caused during hardening process.

- Increase ✔ the toughness ✔ of the steel.

- (Any 1 x 2) (2)

3.4 Factors for heat-treatment processes:

- Heating temperature / Carbon content ✔

- Soaking (Time period at temperature) / Size of the work piece ✔

- Cooling rate / Quenching rate ✔ (3)

3.5 Hardening of steel:

- Steel is heated to 30 – 50°C above the higher critical temperature. (AC3) ✔

- It is then kept at that temperature to ensure (soaking) that the whole structure is Austenite. ✔

- The steel is then rapidly cooled by quenching it in clean water, brine or oil. ✔ (3)

TOTAL QUESTION 3: [14]

QUESTION 4: MULTIPLE-CHOICE QUESTIONS (SPECIFIC)

4.1 B ✔ (1)

4.2 A ✔ (1)

4.3 B ✔ (1)

4.4 B ✔ (1)

4.5 A ✔ (1)

4.6 B ✔ (1)

4.7 D ✔ (1)

4.8 D ✔ (1)

4.9 C ✔ (1)

4.10 C ✔ (1)

4.11 A ✔ (1)

4.12 D ✔ (1)

4.13 B ✔ (1)

4.14 B ✔ (1)

TOTAL QUESTION 4: [14]

QUESTION 5: TERMINOLOGY (TEMPLATES) (SPECIFIC)

5.1 Template loft:

The template loft is separated from the workshop because…

- it is quieter. ✔

- the lighting is better. ✔

- all equipment is at hand. ✔

- it is a permanent base. ✔

- marking on the floor enhance accuracy. ✔

- (Any 2 x 1) (2)

5.2 Purpose of purlins:

- The purlins support ✔ the roof covering ✔

- Stabilizes ✔ the trusses. ✔

- (Any 1 x 2) (2)

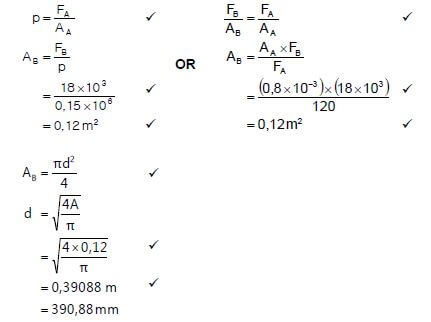

5.3 A steel ring calculation:

5.3.1 Dimensions of the required material:

- Mean diameter = Outside diameter - plate thickness

= 880 - 50

= 830mm - Mean circurmference = π × Meandiameter = ×

= π × 830

= 2607,52mm ✔ - 2608 mm of 50 x 50 mm ✔ square steel bar is required to fabricate the ring. (7)

5.3.2

5.4 Resistance weld symbols:

5.4.1 Spot weld ✔ (1)

5.4.2 Seam weld ✔ (1)

5.5 Welding symbols:

- A. Tail ✔

- B. Weld symbol (Fillet weld) ✔

- C. Pitch of weld ✔

- D. Site weld ✔

- E. Arrow ✔

- F. Weld all round ✔ (6)

TOTAL QUESTION 5: [23]

QUESTION 6: TOOLS AND EQUIPMENT (SPECIFIC)

6.1. Working Principles:

6.1.1 Guillotine:

- A bottom cutting blade is fixed horizontally. ✔

- With a top cutting blade moving downwards. ✔

- It is driven by an electric motor, flywheel, gearbox and axle ✔ by eccentric motion / action / hydraulic action. ✔

- OR

- It is activated manually by foot ✔ with lever action. ✔ (4)

6.1.2 Bending rolls:

- A bending roll has two fixed rollers next to each other rotating in unison (Manually or Electrical motor). ✔

- A third roller is adjustable, moving in between the two rollers. ✔

- The third roller applies downward pressure onto the metal. ✔

- That causes the metal to deflect and ultimately form the round shape desired. ✔ (4)

6.2. Regulators on gas cylinders:

- Regulators reduce ✔ the cylinder pressure ✔ to operating or working pressure. ✔ (3)

6.3 Press machine:

- The press machine is used for installing ✔ or removing ✔ components on mechanical devices / machines. ✔

- To press ✔ profiles ✔ onto material ✔

- (Any 1 x 3) (3)

6.4 MIGS/MAGS welding process:

- A – Weld pool / weld bead / molten metal ✔

- B – Electrode wire / electrode ✔

- C – Gas shroud / electrical contact / nozzle / contact tip ✔

- D – Shielding gas ✔ (4)

TOTAL QUESTION 6: [18]

QUESTION 7: FORCES (SPECIFIC)

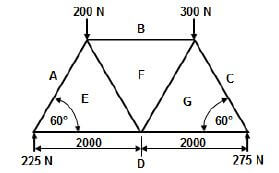

7.1 Forces in members:

SCALE: Vector diagram 1 mm = 5 N  (20)

(20)

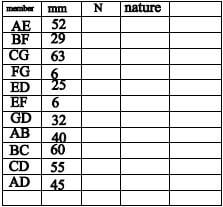

MEMBER | MAGNITUDE | NATURE |

AE | 260 N ✔ | STRUT ✔ |

BF | 135 N ✔ | STRUT ✔ |

CG | 317,5 N ✔ | STRUT ✔ |

FG | 27,5 N ✔ | STRUT ✔ |

ED | 130 N ✔ | TIE ✔ |

EF | 27,5 N ✔ | TIE ✔ |

GD | 160 N ✔ | TIE ✔ |

NOTE:

- Use a tolerance of 2 mm + and – on the vector diagram.

- = a tolerance of 10 N + and – on the answer.

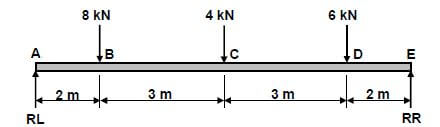

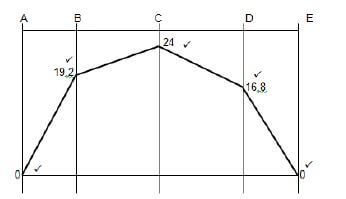

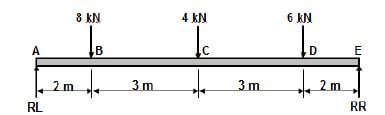

7.2 Bending moments:

7.2.1 Moments about RR

- RL × 10 = (8× 8)+ (4× 5) +(6× 2)

RL = 96

10

= RL 9,6kN ✔

Moments about RL - RR × 10= (6× 8) +(4 × 5) +(8×2)

RR = 84

10

= RR 8,4kN (8)

7.2.2 Bending moments at point A, B, C, D and E:

- Scale2 mm = 1 kN.m

Momentat A = 0 kN.m

B = RL × 2 = 19,2 kN.m

C = (RL × 5) - (8×3) = 24 kN.m

D =(RL×8) -(8×6) - (4×3) = 16,8 kN.m

E = (RL×10) -(8×8) - (4×5) - (6×2) = 0 kN.m (5)

7.2.3  (5)

(5)

NOTE:

- Use a tolerance of 2 mm + and – on the bending moment diagram.

7.3 Stress and strain:

- A = πd2

4

A = π(0,02)2

4

A = 0,314 ×10-3m2 - Stress = Load

Area

Load = Stress c Area

Load = (80 × 106) × (0,314 × 10-3)

Load = 25,133kN ✔(7)

TOTAL QUESTION 7: [45]

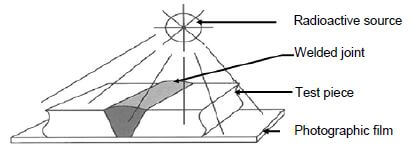

QUESTION 8: JOINING METHODS (WELD INSPECTION) (SPECIFIC)

8.1 Factors to be observed during oxy-acetylene welding:

- Correct flame for the work on hand. ✔

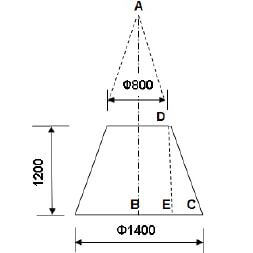

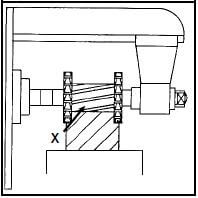

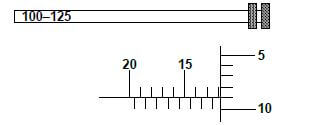

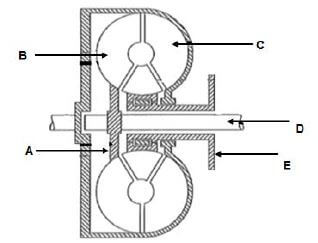

- Correct angle of welding torch and welding rod. ✔