MECHANICAL TECHNOLOGY GRADE 12 MEMORANDUM - NSC PAST PAPERS AND MEMOS FEBRUARY/MARCH 2017

Share via Whatsapp Join our WhatsApp Group Join our Telegram GroupMECHANICAL TECHNOLOGY

GRADE 12

NSC PAST PAPERS AND MEMOS

FEBRUARY/MARCH 2017

MEMORANDUM

QUESTION 1: MULTIPLE-CHOICE QUESTIONS

1.1 B ✔ (1)

1.2 D ✔ (1)

1.3 C ✔ (1)

1.4 C ✔ (1)

1.5 B ✔ (1)

1.6 D ✔ (1)

1.7 A ✔ (1)

1.8 B ✔ (1)

1.9 A ✔ (1)

1.10 B ✔ (1)

1.11 B ✔ (1)

1.12 B ✔ (1)

1.13 D ✔ (1)

1.14 D ✔ (1)

1.15 A ✔ (1)

1.16 C ✔ (1)

1.17 A ✔ (1)

1.18 B ✔ (1)

1.19 B ✔ (1)

1.20 A ✔ (1)

[20]

QUESTION 2: SAFETY

2.1 Safety – Coil spring compressor:

- Make certain that the diameter of the compressor bolts can take the pressure of the coil spring. ✔

- Do not exceed the maximum pressure. ✔

- Make sure the compressors are clean and free from oil. ✔

- Ensure that the compressors are in a good working condition. ✔

(Any 2 x 1) (2)

2.2 Safety – Hydraulic Press:

- Take notice of the predetermined pressure of the hydraulic press. ✔

- Ensure the pressure gauge is in a good working order. ✔

- Platform on which the work piece rests must be rigid and square with the cylinder of the press. ✔

- The prescribed equipment must be used. ✔

- Check for oil leaks. ✔

(Any 3 x 1) (3)

2.3 Safety – beam bender:

- Ensure the beam is clamped parallel to the backboard. ✔

- Do not leave plastic beams loaded for any length of time, they tend to creep. ✔

- All the weight must be gently dropped onto the hanger as to reduce inaccuracies due to friction. ✔

- Do not exceed the tester's maximum load. ✔

- Make sure the tester is stable. ✔

(Any 2 x 1) (2)

2.4 Testers:

2.4.1 Brinell Tester:

- The tester must be mounted rigidly on a worktable. ✔ (1)

2.4.2 Bearing and gear Puller:

- Make sure that the puller is at 90° to the work piece before you start to pull. ✔

- ∙ Ensure that the clamps are tight and will not slip from the work piece. ✔

(Any 1 x 1) (1)

2.4.3 Torsion tester:

- Get specification (torsion) of the different materials and the size of rods you would like to test. ✔ (1)

[10]

QUESTION 3: TOOLS AND EQUIPMENT

3.1 Fuel pressure:

- Faulty diaphragm ✔

- Clogged fuel filter ✔

- Faulty non return valves ✔

- Worn gasket ✔

(Any 2 x 1) (2)

3.2 Precision measuring instruments:

3.2.1 Depth micro-meter ✔

- Vernier calliper ✔

(Any 1 x 1) (1)

3.2.2 Screw-thread micro-meter ✔ (1)

3.3 Depth micro-meter reading:

- Reading = 50 + 1,5+ 0,49 ✔

= 51,99 mm. ✔ (2)

3.4 Multimeter measurements:

- DC current measurement ✔

- DC voltage measurement ✔

- AC measurement ✔

- Resistance measurement ✔

- Diode measurement ✔

- Continuity measurement ✔

(Any 2 x 1) (2)

3.5 Trace the cylinder leakage in an engine:

- Listen to at the carburettor for a hissing noise. ✔

- Listen at the exhaust pipe for a hissing noise. ✔

- Listen for hissing noise in the dipstick hole. ✔

- Listen to hissing noise by removing the filler cap on the tappet cover. ✔

- By checking whether there are bubbles in the radiator water for blown cylinder head gasket or cracked cylinder block. ✔

(Any 2 x 1) (2)

3.6 Uses of cooling pressure tester:

- To test if the pressure cap on the cooling system operates according to the prescribed pressure of the system. ✔

- To pump compressed air into the cooling system to determine whether they are any water leakage in the system. ✔ (2)

[12]

QUESTION 4: MATERIALS

4.1 Properties/characteristics:

4.1.1 Cementite:

- Hard and brittle ✔✔ (2)

4.1.2 Pearlite:

- Good ductility ✔

- Very hard ✔

- Strong and tough ✔

- Resistance to deformation ✔

(Any 2 x 1) (2)

4.2 Iron –carbon equilibrium diagram

4.2.1 Iron –carbon equilibrium diagram ✔ (1)

4.2.2

- – Ferrite + Pearlite ✔

- – Austenite + Ferrite ✔

- – Austenite ✔

- – Austenite + Cementite ✔

- – Ferrite + Cementite ✔ (5)

4.2.3 Austenite:

- Soft, ✔ grain structure fine ✔ (2)

4.3 720 °C ✔ (1)

[13]

QUESTION 5: TERMINOLOGY

5.1 Indexing:

- Indexing = 40 ✔

n

= 40 ÷ 2 ✔

118 2

= 20 ✔ (3)

59

No fullturnsand 20 holes in a 59 -hole plate

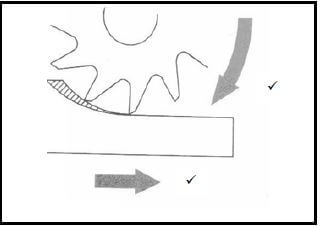

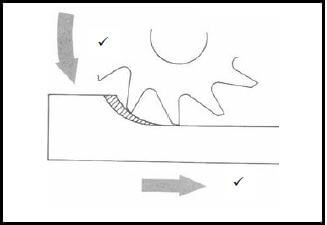

5.2 Milling processes:

- Up-cut milling (2)

- Downcut milling (2)

5.3 Calculate: Gib head key:

5.3.1

- Width = D

4

= 102 ✔

4

= 25,5 mm (2) ✔

5.3.2

- Thickness = D

6

= 102 ✔

6

= 17 mm (2) ✔

5.3.3

- Length = D × 1.5

= 102 × 1.5 ✔

= 153 mm (2) ✔

5.3.4

- Thickness at smallend(t ) T = − L

100

= 17 - 153 ✔

100

t = 17 - 1,53

= 15,47 mm (4) ✔

5.4 Calculate – Spur gear:

5.4.1

- Addendum = m

= 3 mm ✔ (1)

5.4.2

- Dedendum = 1,157m or = 1,25m

= 1,157 x 3 ✔ = 1,25 x 3 ✔

= 3,47 mm ✔ = 3,75 mm ✔ (2)

5.4.3

- Clearance = 0,157m or = 0,25m

= 0,157 x 3 ✔ = 0,25 x 3 ✔

= 0,47 mm ✔ = 0,75 mm ✔ (2)

5.4.4

- Module = PCD

T

PCD = m × T ✔

= 3 × 60

= 180mm ✔(2)

5.4.5

- OD = PCD + 2m

= 180 + 2(3)

= 180 + 6 ✔

= 186 mm ✔ (2)

5.4.6

- Cutting depth = 2,157 m or = 2,25 m

= 2,157 x 3 ✔ = 2,25 x 3 ✔

= 6,47 mm ✔ = 6,75 mm ✔ (2)

5.4.7

- Circular pitch = m x π

= 3 x π ✔

= 9,43 mm ✔ (2)

[30]

QUESTION 6: JOINING METHODS

6.1 Slag inclusion ✔ (1)

6.2 Visual inspection defects

- Shape of profile ✔

- Uniformity of surface ✔

- Overlap ✔

- Undercutting ✔

- Penetration bead ✔

- Root groove ✔

- Crack free ✔

(Any 4 x 1) (4)

6.3 Causes of incomplete penetration:

- Weld speed too fast ✔

- Joint design faulty ✔

- Electrode too large ✔

- Current too low ✔

(Any 2 x 1) (2)

6.4 Prevention of lack of fusion

- Adjust electrode size ✔

- Correct preparation of joint ✔

- Correct weld current ✔

- Correct arc length ✔

- Correct weld speed ✔

(Any 2 x 1) (2)

6.5 Destructive test

6.5.1 Machinability test ✔ (1)

6.5.2 Nick-break test ✔ (1)

6.5.3 Bend test ✔ (1)

6.6 Dye penetration test

- Clean the weld that needs to be tested. ✔

- Spray dye onto the surface and leave to penetrate. ✔✔

- Excess dye is cleaned away with a cleaning agent. ✔

- Allow surface to dry. ✔

- Spray a developer onto the surface to bring out the dye trapped in the crack. ✔

- The dye will show all the surface defects. ✔ (7)

6.7 Functions of MIG/MAGS components

6.7.1 Wire feed controller

- Feeds the consumable electrode wire to the welding gun at a constant predetermined speed. ✔✔ (2)

6.7.2 Welding gun

- Activates the supply of gas, power and wire feed✔✔ (2)

6.8 Purpose of inert gas

- The inert gas shields the molten pool from the atmospheric gases. ✔✔ (2)

[25]

QUESTION 7: FORCES

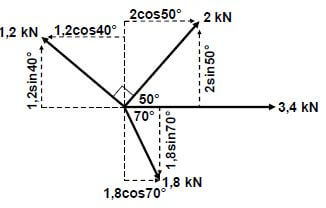

7.1 Forces

∑HC = 3,4 (√) + 1,8cos70º (√) - 1,2cos40º (√) + 2cos50º (√)

= 3,4 + 0,62 - 0,92 + 1,29

= 4,39 kN (√)

∑VC = 1,2 sin40 (√) + 2sin50º (√) - 1,8sin70º (√)

= 0,77 + 1,53 - 1,69

= 0,61 kN (√)

OR

Horizontal component | Magnitudes | Vertical component | Magnitudes |

-1,2cos40°✔ | -0,92 kN | 1,2sin40✔ | 0,77 |

3,4 ✔ | 3,4kN | 0 | 0 |

2cos50°✔ | 1,29kN | 2sin50°✔ | 1,53 |

1,8cos70°✔ | 0,62kN | -1,8sin70°✔ | 1,69 |

TOTAL | 4,39kN ✔ | TOTAL | 0,61kN ✔ |

- R2 = HC2 + VC2

R = √4,392 + 0.612

R = 4,43 kN - Tanθ = VC

HC

= 0,61

4,39

θ = 7,91º

R = 4,43 N at 7,91º northe of east (13)

7.2 Stress and Strain

7.2.1 Stress:

- A = π(D2 - d2)

4

A = π(0,0982 - 0,0672)

4

= 4,02 × 10-3 m2

σ = F

A

σ = 40000

4,02 × 10-3

σ = 9950248,76Pa

σ = 9,95 MPa (5)

7.2.2 Strain:

- ε = σ

E

ε = 9,95 × 106

90 × 109

= 0,11 × 10-3 or 1,11 × 10-4 (3)

7.2.3 Change in length

- ε = ΔI

oI

ΔI = ε × ol

= (0,11 × 10-3) × 0,08

=8,8 × 10-6m

= 8,8 × 10-3 mm (3)

7.3 Moments

Calculate A. Moments about B

- ∑RHM =∑ LHM

(A × 11,6) = (200 × 5,8) + (928 × 5,8) + (600 × 2,8)

11,6A = 1160 + 5382,4 + 1680

11,6A = 8222,4

11,6 11,6

A = 708,83 N

Calculate B. Moments about A

- ∑LHM =∑ RHM

(B × 11,6) = (600 × 8,8) + (928 × 5,8) + (200 × 5,8)

11,6B = 5280 + 5382,4 + 1160

11,6B = 11822,40

11,6 11,6

B = 1019,17 N (6)

[30]

QUESTION 8: MAINTENANCE

8.1 Preventative maintenance

- Can be described as maintenance of equipment or system before a fault occurs.✔ ✔ (2)

8.2 Lock out

- Locking out means that the machine's start switch cannot be activated without the knowledge of a servicing technician otherwise an accident would occur.✔ ✔ (2)

8.3 Clutch free-play

- The distance the pedal moves before the slack is taken from the linkage and release bearing. ✔ ✔ (2)

8.4 Viscosity index

- Viscosity index is a measure of how much the oil's viscosity changes as temperature changes. ✔ (1)

8.5 Replace clutch plate:

- Worn friction linings. ✔

- Weak or broken springs. ✔

- Glazed friction linings due to overheating. ✔

- Oil on friction linings. ✔

(Any 2 x 1) (2)

8.6 Grease – high viscosity

- To ensure that the grease coats and sticks ✔ to the bearing surfaces it is lubricating. ✔ (2)

8.7 Cutting fluid

- Mixture of soluble oil ✔ and water. ✔ (2)

8.8 Viscosity of cutting fluid

- Has a low viscosity to allow easy flow ✔ and effective dissipation of excess heat. ✔ (2)

[15]

QUESTION 9: SYSTEMS AND CONTROL

9.1 Gear drives

9.1.1 Rotation frequency of the output shaft

- NINPUT = TB × TD

NOUTPUT TA × TC

NOUTPUT = TA × TC × NINPUT

TB × TD

NIOTPUT = 18 × 16 × 1660

36 × 46

= 288,70 r/min (3)

9.2.2 Velocity Ratio

- VR = NINPUT

NOUTPUT

= 1660

288,70

= 5,75: 1 (2)

9.2 Belt Drives

9.2.1 Rotation frequency of the driver pulley π(D t) N

- V = π( D + t) × N

60

N = V × 60

π(D + t)

N = 36 × 60

π(230 + 12) × 10-3

2841,11r/min (4)

9.2.2 Power transmitted

- T1 = 2,5

T2

T1 = 2,5 × T2

=2,5 × 110

= 275 N - P = (T1 - T2)V

P = (275 - 110) × 36

= 5940W

5,94kW (4)

9.3 Hydraulics

9.3.1 Fluid pressure

- AB = πD2

4

= π × 0.0752

4

= 4.42 × 10-3 m2 - PB = F

AB

= 700 × 10 Pa

4.42 × 10-3

= 1583710, 41Pa

= 1583, 71 kPa ✔ (4)

9.3.2 Effort on piston A

- AA = πD2

= π × 0.042

4

= 1,256 × 10-3 m2 - PA = FA

AA

FA = PA × AA

=(1583,71 × 103) × (1,256 × 10-3)

= 1990,10 N

= 1,99 kN (4)

9.4 ABS

- Prevents wheel from locking during heavy breaking. ✔✔ (2)

9.5 Seat belt

- A seat belt has to be activated for its safety to be functional. ✔✔ (2)

[25]

QUESTION 10: TURBINES

10.1 Impulse Turbine

- Waterwheel ✔

- Pelton ✔

- Turgo ✔

- Michell – Banki/Crossflow/Ossberger✔

- Jonval turbine ✔

- Reverse overshot waterwheel ✔

- Archimedes' screw turbine ✔

(Any 2 x 1) (2)

10.2 Water turbine

10.2.1

- Water turbine ✔

- Kaplan-turbine ✔

- Reaction turbine ✔

(Any 1 x 1) (1)

10.2.2 Parts

- – Wicked gate ✔

- – Rotor ✔

- – Stator ✔

- – Shaft ✔

- – Water-flow ✔

- – Blades ✔ (6)

10.2.3 Advantages of water turbine

- Low maintenance ✔

- No need for lubrication ✔

- Fewer moving parts ✔

- Environmental friendly ✔

- Cost effective ✔

(Any 2 x 1) (2)

10.3 Turbines

10.3.1 Advantage of supercharger:

- Increases the output power of the engine. ✔

- A smaller engine fitted with a centrifugal blower delivers the same power as a larger engine. ✔

- It eliminates lack of oxygen above sea level. ✔

- Increases the volumetric efficiency of the engine. ✔

- With the aid of the intercooler both the power and the torque output of the engine are increased. ✔

(Any 2 x 1) (2)

10.3.2 Advantages of steam turbines:

- It is compact. ✔

- No lubrication is required. ✔

- Steam turbine speeds can be more accurately regulated. ✔

- A variety of fuels can be used to obtain steam. ✔

- Steam turbines are more economical. ✔

- Higher speeds can be obtained as compared to internal combustion engine. ✔

- Convert heat energy into mechanical energy. ✔

(Any 2 x 1) (2)

10.3.3 Advantages of gas turbines:

- Very high power to weight ratio ✔

- Smaller than most reciprocating engines of the same power rate ✔

- Moves in one direction only, with far less vibration ✔

- Low operating pressures ✔

- High operating speeds ✔

- Low lubricating oil cost and consumption ✔

(Any 2 x 1) (2)

10.4 Turbo lag

- It is a delay ✔ between pushing on the accelerator ✔ and feeling turbo kick in. ✔ (3)

[20]

TOTAL: 200