AGRICULTURAL TECHNOLOGY GRADE 12 MEMORANDUM - NSC PAST PAPERS AND MEMOS FEBRUARY/MARCH 2017

Share via Whatsapp Join our WhatsApp Group Join our Telegram GroupAGRICULTURAL TECHNOLOGY

GRADE 12

NSC PAST PAPERS AND MEMOS

FEBRUARY/MARCH 2017

MEMORANDUM

SECTION A

QUESTION 1

1.1

1.1.1 C✔✔

1.1.2 A✔✔

1.1.3 D✔✔

1.1.4 B✔✔

1.1.5 A✔✔

1.1.6 D✔✔

1.1.7 C✔✔

1.1.8 D✔✔

1.1.9 A✔✔

1.1.10 C✔✔ (10 x 2) (20)

1.2

1.2.1 Aluminium✔✔

1.2.2 Mechanical/motion✔✔

1.2.3 Mechanisation✔✔

1.2.4 Teflon✔✔

1.2.5 Chemicals ✔✔ (5 x 2) (10)

1.3

1.3.1 B✔✔

1.3.2 A✔✔

1.3.3 D✔✔

1.3.4 C✔✔

1.3.5 F✔✔ (5 x 2) (10)

TOTAL SECTION A: 40

SECTION B

QUESTION 2: MATERIALS AND STRUCTURES

2.1

2.1.1 THREE influences of nickel on stainless steel.

- Improves the toughness and the hardening ability.✔

- Gives steel a fair amount of toughness at low temperature.✔

- Steel which is alloyed with chromium and nickel is resistant to air,✔ water and many chemical acids and alkali. (3)

2.1.2 The final product when two or more pure metals are melted together.

- Alloy✔ (1)

2.2 What happens to a metal when it is annealed?

- Metal becomes soft✔ (1)

2.3 TWO reasons why flux residues must be removed after soft soldering.

- To reduce the tendency to cause staining.✔

- To reduce the tendency to cause corrosion.✔ (2)

2.4 A reason why brass, which has been heated to a red hot temperature, should not be cooled in cold water.

- Cracks may be caused✔

- Becomes hard and brittle (Any 1) (1)

2.5 THREE properties of tin.

- Silvery-white in colour✔

- Soft✔

- Malleable✔

- Prevents corrosion/anti-corrosive

- Prevents contamination of food (Any 3) (3)

2.6

2.6.1 Definition of adhesion.

- Ability of the molecules of an adhesive to cling to the molecules of other substances.✔ (1)

2.6.2 TWO important aspects when an adhesive is chosen.

- Type of material to be joined.✔

- Conditions under which this joint will be used.✔ (2)

2.7 FOUR precautionary measures when working with glass fibre.

- Catalyst and accelerator should always be stored separately.✔

- Remove all resin catalyst and accelerator from skin.✔

- Wear gloves if skin is sensitive.✔

- Use acetone in well ventilated room.✔

- Handle resin casting carefully as they are brittle.

- Glass fibre matting has small pieces of fibre that can penetrate the skin.

- Wear nose mask.

- Wear eye protection (Any 4) (4)

2.8 TWO reasons why a vesconite bush is easily removed from a shaft.

- No electrolytic corrosion occurs with vesconite.✔

- It does not seize like metallic bearings.✔ (2)

2.9

2.9.1 THREE factors which cause interference on an electric fence.

- Bad joints✔

- Leaking insulation✔

- Vegetation touching the fence line✔

- People

- Animals

- Bad earthing/dry soil

- Too long distances

- Water (Any 3) (3)

2.9.2 Must be included in the electric game fence where it crosses the pathway of humans.

- A non-electrified✔gate✔ (2)

2.9.3 THREE types of material that can be used as isolators between wires and posts of electric fences to prevent short circuits.

- Ceramic✔

- Rubber✔

- Plastic✔ (Any 3) (3)

2.9.4 TWO types of batteries for an electric fence.

- Disposable/rechargeable battery✔

- 12 volt wet rechargeable battery✔

- Deep cycle battery (Any 2) (2)

2.10

2.10.1 A type of wire that is for constructing an electric fence.

- Steel ✔wire (1)

2.10.2 The minimum thickness of the wire for the electric fence.

- 2–3 mm✔ (1)

2.10.3 A cost-effective process used to protect electric fence components from corrosion.

- Galvanize✔

- Paint (Any 1) (1)

2.10.4 TWO factors when installing the electric fence energizer.

- Constructed so as to exclude dust and water✔

- Not installed in dusty locations✔

- Fire hazard

- Theft

- Damage by animals (Any 2) (2)

[35]

QUESTION 3: ENERGY

3.1

3.1.1 THREE aspects when selecting a wind turbine to generate power for the electric fence on a game farm.

- Surrounding environment/site selection/topography✔

- Cost effectiveness✔

- The average wind speed✔

- Length of the fence

- Capacity

- Theft

- Maintenance (Any 3) (3)

3.1.2 FOUR advantages of using a wind turbine to generate electrical energy.

- Wind power has no fuel costs✔

- Low maintenance costs✔

- Wind power has no clean-up costs✔

- Natural gas and oil imports can be reduced✔

- Do not contribute to air pollution

- Wind is a renewable energy source

- Personal energy independence (Any 4) (4)

3.2

3.2.1 TWO types of energy that are generated directly from solar energy and an example of a device that can effectively convert such type of solar energy for use.

- Heat✔ Solar/sun geyser or solar cooker✔

- Electricity✔ Solar cell/photo-electric cells✔ (4)

3.2.2 The component that is used to change direct current (DC) generated by photovoltaic cells into alternating current (AC).

- Alternator/Inverter/rectifier✔ (1)

3.2.3 The most common semiconducting material used for the manufacturing of solar panels.

- Silicon✔ (1)

3.3

3.3.1 The gas that is used to manufacture methanol fuel and an example for the gas source.

- Methane gas✔ (1)

- Rubbish dump/sewage/manure✔ (Any 1) (1)

3.3.2 TWO advantages of methanol fuel.

- It offers lower exhaust emissions and higher vehicle performance.✔

- It can easily be made into hydrogen, offering a promising future for use in methanol fuels cells.✔

- Methanol has a lower risk of flammability than gasoline. (Any 2) (2)

3.4 Describe how geothermal steam is used to generate electricity.

- The pressurized steam is channelled to a turbine which begins to turn under the large force of the steam.✔

- This turbine is linked to the generator✔ that generates electricity.✔ (3)

[20]

QUESTION 4: SKILLS AND CONSTRUCTION PROCESSES

4.1

4.1.1 THREE settings on the MIG welding machine that must be done before welding.

- Welding current/arc strength/arc force/power✔

- Gas supply pressure/working pressure. (Between 15 and 25 PSI) ✔

- Speed of the wire feed✔

- Appropriate shielding gas

- Time setting for continuous welding (Any 3) (3)

4.1.2 Sound that the MIG welding process makes.

- Continuous sparking✔

- An egg frying sound✔ (2)

4.1.3 Wrong setting on the MIG welding machine when holes occur when welding.

- The power of the welding machine is too high.✔ (1)

4.2

4.2.1 How must an oxy-acetylene flame be extinguished after completing a welding job?

- Turn off the acetylene valve on the torch handle.✔

- This will extinguish the flame.✔

- Turn off the oxygen valve on the torch handle.✔

- Next, remove your safety goggles or mask and your welding gloves.✔

- Turn the main cylinder valve clockwise on the top of both gas cylinders to close the bottles.✔

- Now open the two valves on the torch handle to 'bleed' the system.

- Turn both the oxygen and acetylene regulator handles counter clockwise until they are loose.

- Close both valves on the torch handle.

- Put the handle and tips away, and return the gas cylinders and their hoses to their proper storage area. (Any 5) (5)

4.2.2 Symptoms experienced when inhaling welding vapours from galvanized steel.

- Flu like symptoms✔ (fever/headaches/red eyes/sinus) (1)

- Heavy metal poisoning✔ (welding shivers) (1)

4.3

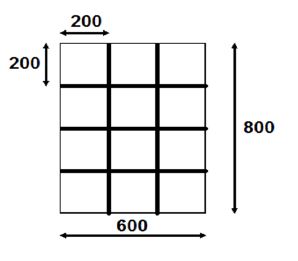

4.3.1 Drawing of the burglar proofing.

- Drawing of burglar bars in frame: (Horizontal x 3 ✔and Vertical x 2✔) 2 marks

- Dimensions✔ 1 mark • Spacing off the bars✔ 1 mark (4)

4.3.2 Calculate the cost of the materials to be used for manufacturing the burglar proofing bars.

- Total length of horizontal square bars is:

(600 mm x 3 = 1800 mm) + (800 mm x 2 = 1600 mm) = 3400 mm✔

= 3,4 metres✔ - Price of square bar is R5,00 x 3,4 m

= R15,20✔ (3)

4.4 Discussion of the overhead arc welding technique.

- Use an arc as short as possible.✔

- Weld a number of runs without any side wards movement.✔

- When molten metal starts dripping, the amperage should be reduced slightly.✔

- Move electrode slightly faster.✔

- Hold electrode in same position as in relation to base metal.✔ (5)

4.5 THREE circumstances for using the horizontal square butt welding joint.

- When two pieces of metal less than 6 mm in thickness are welded.✔

- The metal is in an upright position.✔

- One work piece is on top of the other.✔ (3)

4.6

4.6.1 Information source to consult for choosing the correct eye protection for plasma cutting.

- User manual✔

- Internet

- Supplier (Any 1) (1)

4.6.2 THREE advantages of a plasma cutting machine over the oxy-acetylene cutting set.

- Rapid cutting speeds✔

- Wide range of metals and thickness✔

- Easy to use✔

- Economical (Any 3) (3)

4.7 Explanation of the end result if the air filters on the plasma cutting machine becomes saturated with moisture.

- Moisture is going to penetrate the machine.✔

- The moisture entering the torch is highly conductive✔and can cause internal arcing ✔that can damage the torch. (Any 3) (3)

[35]

QUESTION 5: TOOLS, IMPLEMENTS AND EQUIPMENT

5.1 FIVE safety measures applicable when using a push lawn mower.

- Read and understand the operator's manual and become familiar with the machine.✔

- Remove all debris from lawns before mowing.✔

- Use recommended PPE (Personal Protective Equipment) including closefitting clothing when operating a lawn mower.✔

- Disengage the blade before starting.✔

- Keep all guards and safety shields in place.✔

- Never disengage any safety interlock switches.

- Never refuel the mower when the engine is hot or running.

- Store gasoline in an approved container with proper label.

- Turn off the motor before cleaning the area under the deck.

- Disconnect the spark or electric plug before trouble-shooting or repairing the mower.

- Perform routine maintenance according to the schedule recommended by the manufacturer.

- Keep a running mower away from bystanders and pets. (Any 5) (5)

5.2

5.2.1 Device that allows the power take-off shaft to operate at an angle.

- Universal joint✔ (1)

5.2.2 TWO requirements of power take-off shaft screens.

- Strong✔

- Not become lose/tight✔

- Weight saving/Light

- Must provide sufficient protection (Any 2) (2)

5.3

5.3.1 Reason why a combine harvester breaks the kernels.

- Happens when the drum speed✔is incorrect✔ (2)

5.3.2 Reason why the kernels are blown out with the chaff.

- The blower ✔of the combine harvester creates too much wind.✔ (2)

5.4 The part of the hammer mill that is responsible for each of the following:

5.4.1 Pulverize the feed.

- Rotor and hammer✔ (1)

5.4.2 Determine the size of the final ground product.

- Sieve✔ (1)

5.4.3 Separate the ground material effectively from the air.

- Cyclone✔ (1)

5.5 The procedure to follow when the silage cutter is prepared for use.

- All grease points must be well greased.✔

- The correct tension must be set for all belts or chains.✔

- Check that all parts are functioning correctly by operating it slowly.✔

- Replace all worn parts immediately especially the cutter blades.✔

- Service according to manufacturer's specifications.✔

- Lift up all dust release guards.

- Check that there is no damage to the blades and that they are sharp. (Any 5) (5)

5.6 Preventative measures that the operator must keep in mind to prevent the following injuries:

5.6.1 The driver injured by a falling bale.

- The tractor should have roll-over protective structures.✔

- Do not lift or carry the bale too high.

- Carry the bale in the front of the tractor. (Any 1) (1)

5.6.2 Bystanders injured by a bale falling from the loader.

- Never drive close near people.✔

- Never walk or work under a raised loader.

- Never move or swing a load as long as people are in the work area. (Any 1) (1)

5.6.3 Side overturn of the tractor on a steep slope.

- Never work with two wheels on the downhill side and two wheels on uphill side.✔

- As the bale is lifted, the centre of gravity gets higher and the potential for the tractor to roll down the slope increases. (Any 1) (1)

5.7

5.7.1 TWO safety mechanisms used in ram type baling machine.

- Slip clutch✔

- Screens✔

- Shear bolts

- Ram stop (Any 2) (2)

5.7.2 Function of the auger in the ram type baling machine.

- The auger constantly rotates✔ and feeds the hay✔ to the packing arms.✔ (3)

5.8 Name the parts that are used to connect an implement to the tractor.

- Two lifting arms✔

- Top link✔

- Two stabilising chains✔ (3)

5.9 THREE shafts that are found in the manual gearbox of a tractor.

- Main shaft/Input shaft✔

- Counter shaft✔

- Output shaft✔ (3)

5.10 Comparison of the two different types of drive belts.

V-BELT | FLAT BELT | |

Alignment | 5.10.1 V-belts do not easily slip off dis-aligned pulleys.✔ | 5.10.2 If the pulleys over which they run are not aligned accurately the flat belt is thrown off.✔ |

Speed | 5.10.3 V-belts can accommodate low and high speed.✔ | 5.10.4 Flat belts only low speed.✔ |

Lubrication | 5.10.5 Lubrication is never necessary with a V-belt.✔ | 5.10.6 If flat belts are not lubricated regularly, they tend to slip on pulleys.✔ |

(6)

[40]

QUESTION 6: WATER MANAGEMENT

6.1

6.1.1 Calculation of the length and costs of the pipes.

- 13 x 100 m = 1 300 m✔ of pipe

1 300 m x R6,50 ✔

= R8 450,00✔ (3)

6.1.2 Calculation of the total cost of T-joints and elbows

- 19 x R8,00 = R152,00✔

- 4 x R6,50 = R26,00✔

- Total Cost: R152,00 + R26,00 = R178,00✔ (3)

6.2 The function of a one-way irrigation valve.

- An irrigation valve regulates✔the one-directional flow✔of water in an irrigation system.✔ (3)

6.3 FOUR reasons for preferring sprinkler irrigation to flood irrigation.

- When water supply is weak✔

- Surface gradient (steep) leads to erosion✔

- Infiltration tempo not constant✔

- Drainage problems with the soil✔ (4)

6.4 The safety feature that is built into the centre pivot irrigation system to prevent it from falling when one of the wheels gets stuck.

- When the system gets out of line✔a safety switch cuts the electricity to the wheels✔preventing the other wheels from moving forward.✔ (3)

6.5 THREE important reasons why a farmer will choose a drip irrigation system instead of an overhead irrigation system.

- Water saving✔

- Application of herbicides✔

- Liquid fertiliser can be given effectively through this system on the spot✔

- More economical✔ (4)

6.6 TWO types of equipment that can be used to determine evaporation in a specific field.

- Tensio-meter✔

- Evaporation pan/class-A pan✔

- Neutron probe (Any 2) (2)

6.7 THREE types of irrigation systems that can be used by farmers to water large fields.

- Flood irrigation✔(furrow/bed irrigation)

- Hand moved sprinkler pipes✔

- Centre Pivot (Drop down pipes) or high fixed sprinklers✔ (3)

6.8 A problem that is commonly experienced by irrigation farmers.

- Rivers that dries up✔

- Price of water

- Low water quotas

- Pollution-heavy metals (Any 1) (1)

6.9 Kind of capital.

6.9.1 Fixed capital✔ (1)

6.9.2 Working or floating capital✔ (1)

6.9.3 Working or floating capital✔ (1)

6.9.4 Moveable capital✔ (1) [

30]

TOTAL SECTION B: 160

GRAND TOTAL: 200