MECHANICAL TECHNOLOGY(FITTING & MACHINING) GRADE 12 MEMORANDUM - NSC PAST PAPERS AND MEMOS NOVEMBER 2021

Share via Whatsapp Join our WhatsApp Group Join our Telegram GroupMARKING GUIDELINES

QUESTION 1: MULTIPLE-CHOICE QUESTIONS (GENERIC)

1.1 B (1)

1.2 A (1)

1.3 D (1)

1.4 A / C (1)

1.5 A (1)

1.6 C (1)

[6]

QUESTION 2: SAFETY (GENERIC)

2.1 First-aid applications to an open wound:

- Use surgical gloves.

- Do not remove anything that is stuck to the wound.

- Never use sticky plaster on the wound.

- Cover the wound with a clean, lint-free cloth.

- Avoid using any oily substances or lotions on wounds.

- If necessary, cool wounds with cold water.

- Apply pressure to prevent blood loss if necessary.

- Avoid contact with blood from patient.

- If the wound is on your arm, raise the arm above your head to stop the bleeding.

(Any 2 x 1) (2)

2.2 Surface grinder: (Already switched on)

- Never leave the grinder unattended.

- Switch off the machine when leaving.

- Don’t try to stop revolving emery wheel with your hand.

- Don’t adjust the machine while working.

- Don’t open any guard while the machine is on.

- Do not force the grinding wheel on to the work piece.

- Approach the work piece slowly and evenly.

- Don’t clean the machine while working.

- Do not put hands near the work piece when grinder is in motion.

- Don’t clean or adjust the machine while working.

- Check for oil on the floor while working (spilling of cutting fluid on floor while working)

- Check that he grinding wheel is running evenly.

(Any 2 x 1) (2)

2.3 Gauges calibrated:

- To ensure accurate readings.

- To prevent overloading.

(Any 1 x 1) (1)

2.4 Finger protectors’ hazards on power driven guillotines:

- The finger protector prevents the hazards of getting the fingers cut by the blades.

- To be crushed by the hold-downs. (2)

2.5 Welding or flame cutting operation safety:

- An operator has been instructed on how to use the equipment safely.

- A workplace is effectively partitioned off.

- An operator uses protective equipment.

- Ensure that all equipment is in safe working condition.

- Ensure that here are no flammable materials around the welding area.

- Weld area must be well ventilated.

- Fire extinguisher must be in close proximity.

(Any 2 x 1) (2)

2.6 Workshop layout:

- Product layout. (1)

[10]

QUESTION 3: MATERIALS (GENERIC)

3.1 File test:

3.1.1 Difficult (1)

3.1.2 Easy (1)

3.1.3 Difficult (1)

3.2 Heat treatment:

- A. – Grain growth.

- B. – Recrystallisation.

- C. – Recovery. (3)

3.3 Bending test:

- Bend the test piece through a specific angle or around a mandrel or bar, having a defined radius, until a rupture in the metal occurs.

- Place the material in a vice and bend it then observe the ductility of the material.

(Any 1 x 3) (3)

3.4 Purpose of case hardening:

- Creates a hard surface with a tough core. (2)

3.5 Quenching media:

- Water

- Brine (saltwater)

- Oil

- Soluble oil and water

- Nitrogen air-infused air

(Any 3 x 1) (3)

[14]

QUESTION 4: MULTIPLE-CHOICE QUESTIONS (SPECIFIC)

4.1 C (1)

4.2 B (1)

4.3 A (1)

4.4 A (1)

4.5 D (1)

4.6 D (1)

4.7 C (1)

4.8 C (1)

4.9 B / D (1)

4.10 D (1)

4.11 A (1)

4.12 A (1)

4.13 B (1)

4.14 D (1)

[14]

QUESTION 5: TERMINOLOGY (LATHE AND MILLING MACHINE) (SPECIFIC)

5.1 Advantages of compound slide method:

- Tapers with large angles can be cut.

- External and internal tapers can be cut.

- The set-up is simple.

(Any 2 x 1) (2)

5.2 Taper cutting:

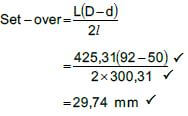

5.2.1 Length of taper:

(5)

5.2.2 Tailstock set-over:

(3)

5.3 Key ways:

5.3.1 Width:

Width = D/4

Width = 75 ?

= 18,75 mm ? (2)

5.3.2 Thickness:

Thickness = D/6

Thickness = 75/6

= 12,50 mm ? (2)

5.3.3 Length:

Length= 1,5 x diameterof shaft

= 1,5 x 75

= 112,50 mm ? (2)

5.4 Disadvantages of down-cut milling:

- Vibration in the arbor is unavoidable.

- A fine feed must be used.

- When milling material with hard scale, the cutter teeth come directly in contact with the scale, which can damage the cutter.

- The process is time consuming.

(Any 2 x 1) (2)

[18]

QUESTION 6: TERMINOLOGY (INDEXING) (SPECIFIC)

6.1 Gear terminology:

6.1.1 Pitch-circle diameter:

- PCD = m x T

= 1,5 x 200 ? OR CP = m x π

= 300 mm? = 1,5 x π

= 4,71mm ?

PCD = CP x T

π

= 4,71 x 200

π

= 299,85mm ? (2)

6.1.2 Dedendum:

- Dedendum= 1,157 x m Dedendum= 1,25 x m

= 1,157 x 1,5 ? OR = 1,25 x 1,5

= 1,74 mm ? = 1,88 mm ? (2)

6.1.3 Outside diameter:

- OD = PCD + 2 x m OD = m(T + 2)

= 300 + 2(1,5) ? OR = 1,5(200 + 2) ?

= 303 mm ? = 303 mm ? (2)

6.1.4 Working depth:

- WD = 2 x m WD = 2 x a

= 2 x 1,5 ? OR = 2 x 1,5

= 3 mm ? = 3 mm ? (2)

6.2 Dovetails:

- W = 210 + 2(DE)

m = W – 2(AC) – 2(R)

6.2.1 Maximum width distance of dove tail: (W)

Calculate DE or y:

- tanθ = DE

AD

DE = tanθ x AD ?

= tan30°x 45

= 25,98 mm ?

W = 210 + 2(DE) ?

= 210 + 2(25,98) ?

= 210 + 51,96

= 261,96 mm ? (6)

6.2.2 Distance between the rollers: (m)

Calculate AC or x:

- Tanθ = BC

AC

AC = BC ?

Tanθ

AC = 17 ?

Tan30º

= 29,44mm ?

m = W - 2(AC) - 2(R) ?

= 261,96 - 2(29,44) - 2(17) ?

= 261,96 - 58,88 - 34

= 169,08 mm ? (6)

6.3 Milling of spur gear:

6.3.1 Indexing:

- Indexing = 40 = 40

N 137

= 40 = 40

A 140

= 4 x 2

14 2

= 8 ?

28 - Indexing: 8 holeson a 28 - hole circle ?

OR

- 12 holeson a 42 - hole circle ?

OR

- 14 holes on a 49-hole circle. ? (3)

6.3.2 Change gears: (Markers to note alternative answers and calculations to award full marks if the answer is correct)

- Dr=( A - n) x 40

Dn A

Dr =(140 - 137) x 40 ?

Dn 140

= 3 x 40

140

= 120/140

= 12/14 x 2/2

Dr = 24 OR 48 ?

Dn 28 ? 56 ?(5)

[28]

QUESTION 7: TOOLS AND EQUIPMENT (SPECIFIC)

7.1 Functions of a moment and force tester:

- To determine the reaction on either side of a simple loaded beam.

- To illustrate the concept of the triangle of force. (2)

7.2 TWO hardness testers:

- Brinell

- Rockwell

- Vickers

(Any 2 x 1) (2)

7.3 Precision measuring instrument:

- Depth micrometer

- Vernier caliper

(Any 1 x 1) (1)

7.4 Identify tester:

- Tensile tester (1)

7.5 There are THREE ways that hardness is measured:

- Resistance to penetration.

- Elastic hardness.

- Resistance to abrasion / scratching / file test.

- Sound test (dropping it on the floor and listen to the sound).

(Any 3 x 1) (3)

7.6 Screw thread height:

- H = 0,866 x P

= 0,866 x 2

= 1,73 mm (2)

7.7 Measuring instrument:

- Vernier caliper (1)

7.8 Interchangeable extension:

- To measure depths greater than 25 mm. (1)

[13]

QUESTION 8: FORCES (SPECIFIC)

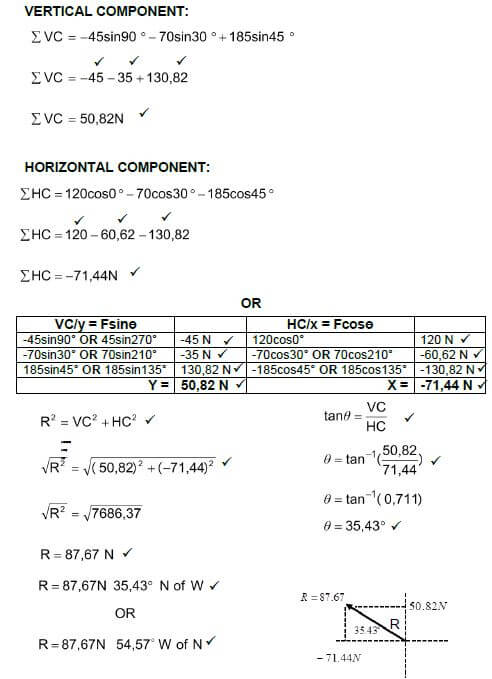

8.1 Calculate resultant:

(15)

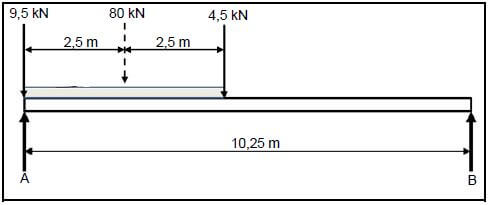

8.2 Moments:

8.2.1 Point load for UDL:

- 16kN/m x 5m

80 kN (2)

8.2.2 Take moments about B:

- A x 10,25) = (4,5 x 5,25) + (80 x 7,75) + (9,5 x 10,25)

10,25A = 23,625 + 620 + 97,375

A = 741/10,25

A = 72,29 kN (3)

8.2.3 Take moments about A:

- B x 10,25) = (9,5 x 0) + (80 x 2,5) + (4,5 x 5)

10,25B = 0 + 200 + 22,5

B = 222,5/10,25

B = 21,71kN (3)

8.3.1 The stress in the material in MPa:

- σ = F/A

σ = 90 x 103

6,17 x 10-3

σ = 14586709,89 Pa

σ = 14,59 MPa (2)

8.3.2 The diameter of the mild steel shaft:

(5)

8.3.3 Original length:

(3)

[33]

QUESTION 9: MAINTENANCE (SPECIFIC)

9.1 Preventative maintenance:

- Planned or scheduled maintenance.

- Condition-based maintenance. (2)

9.2 Preventative maintenance of gear drive systems:

- Checking and replenishment of lubrication levels.

- Ensuring that gears are properly secured to shafts.

- Cleaning and replacement oil filters.

- Reporting excessive noise, wear, vibration and overheating for expert attention.

(Any 3 x 1) (3)

9.3 Purpose of jockey pulley:

- The jockey pulley helps setting the tension on the system.

- To increase the angle of contact in an open belt drive.

(Any 1 x 1) (1)

9.4 Properties of materials:

9.4.1 Teflon:

- Water resistant.

- Resistant to grease.

- Resistant to heat.

- Resistant to corrosion.

- Can withstand high temperatures.

- Need no lubricants.

- Electrical insulator

- Thermoplastic /Easy to be reshaped / recycled.

(Any 2 x 1) (2)

9.4.2 Nylon:

- Tough.

- Hard-wearing.

- Cheap.

- Needs no or little maintenance.

- Can withstand high temperatures.

- Need no or little lubricants.

- Is light.

- Can absorb shock.

- Resistant to chemicals.

- Non-toxic.

- Thermoplastic /Easy to be reshaped.

- Has high load-bearing strength

(Any 2 x 1) (2)

9.4.3 Vesconite:

- Wear resistant.

- Low friction.

- Operate with little or no lubrication.

- Easy to machine.

- Load carry higher than white metal.

- Cost effective material.

- Gives long life span.

- Performs well, in unhygienic, dirty and un-lubricated environments.

- Low maintenance.

- Low or no water absorption

- High chemical resistance

- Versatile

- Can handle high temperatures

- Thermoplastic /Easy to be reshaped

(Any 2 x 1) (2)

9.5 Use of material:

9.5.1 Polyvinyl chloride (PVC): (Due to the large number of alternatives, marker discretion must be used - discuss with IM).

- Electrical cable isolation.

- Electrical pipes.

- Water pipes.

- Artificial leather.

- Cling wrap.

- Credit / bank / phone cards.

- Window frames.

- Fences.

- Furniture.

(Any 1 x 1) (1)

9.5.2 Glass fibre: (Due to the large number of alternatives, marker discretion must be used - discuss with IM).

- Boats.

- Motor vehicles bodies.

- Transparent roof sheeting.

- Petrol tanks.

- Swimming pools.

- Furniture.

- Fruit and salad bowls.

- Ornaments.

- Fishing equipment.

(Any 1 x 1) (1)

9.6 Difference between thermoplastic and thermo-hardened composites:

- Thermoplastic can be re-heated and reshaped again where a thermo- hardened plastic cannot be re-heated, to be softened, shaped and moulded again. (4)

[18]

QUESTION 10: JOINING METHODS (SPECIFIC)

10.1 Screw thread:

- Square thread

- Acme thread

- V-screw thread

- Trapezium thread / Buttress thread

(Any 3 x 1 ) (3)

10.2 Square Thread:

10.2.1 Pitch diameter:

- Pitch = Lead /Numberof starts

= 36/2

=18 mm ?

PD = OD - P/2

= 80 - 18/2

= 71 mm ? (4)

10.2.2 Helix angle of the thread:

- Tanθ = Lead

π x PD

Tanθ = 36

π x 71 ?

θ = tan-1(0,161396562)

= 9,17º (4)

10.2.3 Leading angle:

- Leading angle = 90° - (helix angle + clearance angle)

= 90° - (9,17° + 3°)

= 77,83° (2)

10.2.4 Following angle:

- Following angle = 90° + (helix angle - clearance)

= 90° + (9,17° - 3°)

= 96,17° (2)

10.3 Multiple screw threads:

- They provide more bearing surface than single start screw thread / does not strip easily.

- To provide faster linear movement.

- They are more efficient as they lose less power to friction compared to single start screw threads. (3)

[18]

QUESTION 11: SYSTEMS AND CONTROL (DRIVE SYSTEMS) (SPECIFIC)

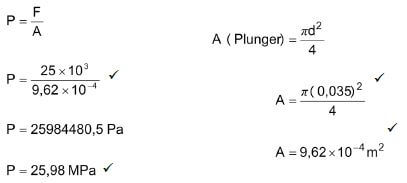

11.1 Hydraulics:

11.1.1 The fluid pressure:

(4)

11.1.2 Force at ram:

(5)

11.2 Functions hydraulic reservoir:

- A fluid storage tank.

- Promotes air separation from the fluid.

- Support for the pump and electric motor.

- Promotes heat dispersion.

- Acts as a base plate for mounting control equipment.

- Permits contaminants to settle at the bottom in order to be drained.

(Any 1 x 1) (1)

11.3 Efficiency of pneumatic systems:

- Pneumatic tools are environmentally friendly.

- Last long.

- It is robust (powerful / less force required)

- Easy to use.

- It is compact.

- Easy to maintain as there are so few working parts.

(Any 2 x 1) (2)

11.4 Applications for pneumatic systems: (Due to the large number of alternatives, marker discretion must be used - discuss with IM).

- Drills.

- Brake systems.

- Jackhammers

- Nail guns

- Missiles

- Doors

- Spray guns

- Air blow guns

- Air socket wrench

- Grinders

(Any 2 x 1) (2)

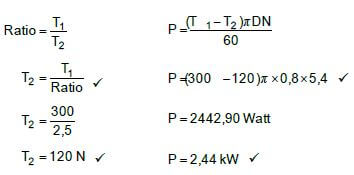

11.5 Belt drives:

11.5.1 Rotation frequency:

(3)

11.5.2 Power transmitted:

(4)

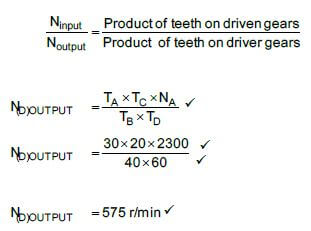

11.6 Gear drives:

11.6.1 Rotation frequency:

(4)

11.6.2 Gear ratio:

- Gear ratio = Product of teeth on driven gears/Product of teeth on driver gears

Gear ratio = 40 x 60

30 x 20

Gear ratio = 4 : 1

OR

- Speed ratio = NA

ND

= 2300

575

= 4:1 (3)

[28]

TOTAL: 200