MECHANICAL TECHNOLOGY(FITTING & MACHINING) GRADE 12 QUESTIONS - NSC PAST PAPERS AND MEMOS NOVEMBER 2021

Share via Whatsapp Join our WhatsApp Group Join our Telegram GroupINSTRUCTIONS AND INFORMATION

- Write your centre number and examination number in the spaces provided on the ANSWER BOOK.

- Read ALL the questions carefully.

- Answer ALL the questions.

- Number the answers correctly according to the numbering system used in this question paper.

- Start EACH question on a NEW page.

- Show ALL calculations and units. Round off final answers to TWO decimal places.

- Candidates may use non-programmable scientific calculators and drawing instruments.

- The value of gravitational acceleration should be taken as 10 m/s2.

- All dimensions are in millimetres, unless stated otherwise in the question.

- Write neatly and legibly.

- A formula sheet is attached at the end of the question paper.

- Use the criteria below to assist you in managing your time.

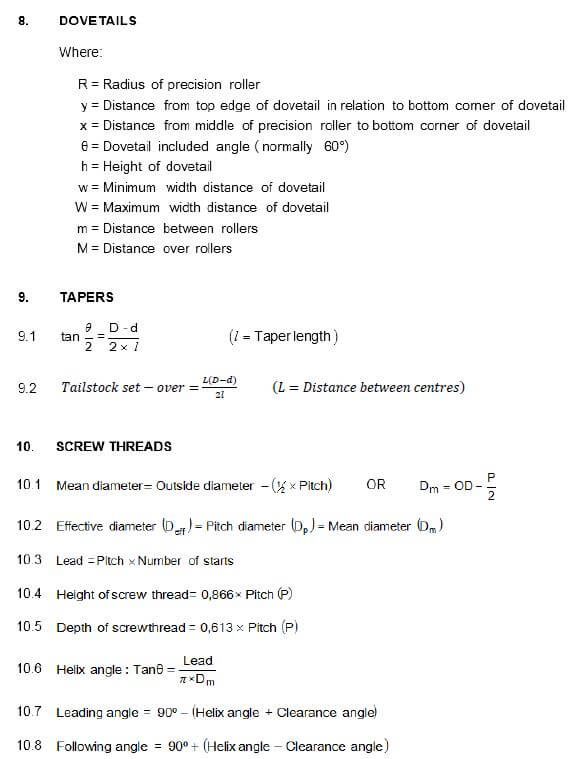

| QUESTION | CONTENT | MARKS | TIME IN MINUTES |

| GENERIC | |||

| 1 | Multiple choice questions | 6 | 6 |

| 2 | Safety | 10 | 10 |

| 3 | Materials | 14 | 14 |

| SPECIFIC | |||

| 4 | Multiple choice-questions | 14 | 10 |

| 5 | Terminology (Lathe ad Milling machine) | 18 | 20 |

| 6 | Terminology (Indexing) | 28 | 25 |

| 7 | Tools and equipment | 13 | 10 |

| 8 | Forces | 33 | 33 |

| 9 | Maintenance | 18 | 12 |

| 10 | Joining methods | 18 | 12 |

| 11 | Systems and control (Drive systems) | 28 | 28 |

| TOTAL | 200 | 180 | |

QUESTIONS

QUESTION 1: MULTIPLE-CHOICE QUESTIONS (GENERIC)

Various options are provided as possible answers to the following questions. Choose the answer and write only the letter (A–D) next to the question numbers (1.1 to 1.6) in your ANSWER BOOK, e.g. 1.7 E.

1.1 What is the code of good practice for HIV/Aids and employment?

- Persons with HIV/Aids must use separate dining halls.

- The Act contains common guidelines on how employers and employees should respond to HIV/Aids in the workplace.

- The Act contains guidelines on how much work an employee is supposed to do.

- It contains the daily working hours of employees. (1)

1.2 Which ONE of the following types of personal protective equipment (PPE) is required when working in a workshop with Covid-19 regulations?

- Mask

- Sunglasses

- Welding helmet

- Clear goggles (1)

1.3 The … is responsible for the provision of safety gear in the workshop.

- employees

- cleaning staff

- foreman

- employer (1)

1.4 Which ONE of the following describes the reaction of mild steel when it is cut on a machine?

- Cuts easily; black crumbly chips

- Hard to cut; cuttings break in sharp chips

- Cuts easily; curly chips

- Hard to cut (1)

1.5 The purpose of hardening steel is to …

- resist wear.

- relieve strain.

- increase softness.

- quench the material. (1)

1.6 Which process follows on from hardening?

- Normalising

- Annealing

- Tempering

- Case hardening (1)

[6]

QUESTION 2: SAFETY (GENERIC)

2.1 Explain TWO first-aid measures to consider when treating an open wound. (2)

2.2 State TWO safety precautions that must be adhered to after the surface grinder has been switched on. (2)

2.3 Give ONE reason why the pressure gauge of a hydraulic press must be calibrated frequently. (1)

2.4 Which TWO hazards are prevented by the finger protectors fitted to power-driven guillotines? (2)

2.5 State TWO safety measures to be considered before gas welding or flame cutting operations can be performed. (2)

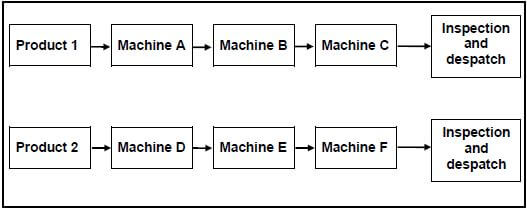

2.6 Which type of workshop layout is shown in FIGURE 2.6 below?

FIGURE 2.6 (1)

[10]

QUESTION 3: MATERIALS (GENERIC)

3.1 Describe the filing process as easy or difficult when conducting a file test for hardness on the following materials:

3.1.1 Cast steel (1)

3.1.2 Mild steel (1)

3.1.3 High-speed steel (1)

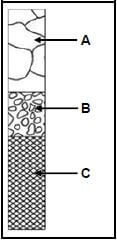

3.2 FIGURE 3.2 below shows the annealing process during heat treatment. Label components A–C.

FIGURE 3.2 (3)

3.3 Describe how a bending test is conducted to determine the properties in a test metal. (3)

3.4 State the purpose of case hardening of steel. (2)

3.5 Name THREE types of quenching media that could be used to harden steel. (3)

[14]

QUESTION 4: MULTIPLE-CHOICE QUESTIONS (SPECIFIC)

Various options are provided as possible answers to the following questions. Choose the answer and write only the letter (A–D) next to the question numbers (4.1 to 4.14) in the ANSWER BOOK, e.g. 4.15 E.

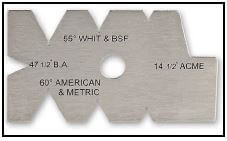

4.1 Identify the type of gauge shown in FIGURE 4.1 below. It is used during the setting up of a screw-cutting tool on a centre lathe.

FIGURE 4.1

- Pressure gauge

- Screw-cutting dial gauge

- Thread centre gauge

- Thread-pitch gauge (1)

4.2 What is the maximum angle that the head of the vertical milling machine can be swivelled in the vertical plane?

- 30°

- 45°

- 60°

- 90° (1)

4.3 What is the function of the sector arms found on a dividing head?

- To enable indexing where fractions of turns is required

- Keeping the index plate in place

- It breaks the round work piece into a number of equal parts

- It disengages the worm shaft from the worm wheel (1)

4.4 On which principle does an incremental cutter in a CNC milling machine operate?

Each point influences the …

- following point.

- previous point.

- immediate point.

- following and the previous points. (1)

4.5 Which instrument must be used to measure the indentation made by the carbide ball of the Brinell hardness tester?

- Vernier calliper

- Steel ruler

- Depth micrometer

- Microscope (1)

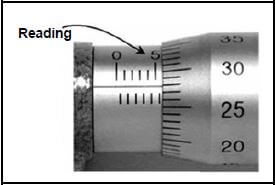

4.6 What is the reading on the 0–25 mm screw-thread micrometer in FIGURE 4.6 below?

FIGURE 4.6

- 6,78 mm

- 6,28 mm

- 5,28 mm

- 5,78 mm (1)

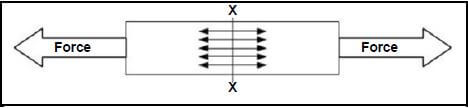

4.7 Describe the type of stress caused in the material as shown in FIGURE 4.7 below.

FIGURE 4.7

- Compressive stress

- Shearing stress

- Tensile stress

- Twisting stress (1)

4.8 What does the term shearing stress mean?

It is a force that exists on a body, if on …

- the same faces of the section, equal and compressive forces exist.

- opposite faces of the section, unequal forces exist.

- opposite faces of the section, equal and opposite parallel forces exist.

- faces of the same section, unequal and opposite parallel forces exist. (1)

4.9 Nylon is a ...

- natural material.

- synthetic material.

- thermosetting plastic.

- material that has high load-bearing strength. (1)

4.10 At what temperature is graphite formed in an oven during the manufacturing of carbon fibre?

- 100 °C–150 °C

- 200 °C–300 °C

- 1 000 °C

- 2 500 °C (1)

4.11 A single-start screw thread is used on fasteners where …

- locking power is required.

- minimum holding power is needed.

- less force is needed.

- only reduced friction is required. (1)

4.12 The helix angle is the angle that the thread makes with a line … to the axis of the screw thread.

- 90°

- 60°

- 55°

- 180° (1)

4.13 Identify the type of gear shown in FIGURE 4.13 below.

FIGURE 4.13

- Spur gear

- Helical gear

- Worm gear

- Rack gear (1)

4.14 Identify the hydraulic symbol shown in FIGURE 4.14 below:

FIGURE 4.14

- Adjustable flow control gauge

- Directional control gauge

- Fixed flow control gauge

- Pressure gauge (1)

[14]

QUESTION 5: TERMINOLOGY (LATHE AND MILLING MACHINE) (SPECIFIC)

5.1 State TWO advantages of cutting a taper on a lathe machine by using the compound slide method. (2)

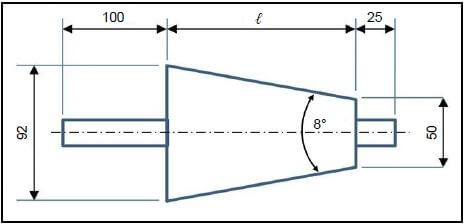

5.2 FIGURE 5.2 below shows a taper with an included angle of 8°. Answer the questions that follow.

FIGURE 5.2

Calculate the following:

5.2.1 The length of the taper (5)

5.2.2 The set-over of the tailstock required to cut the taper (3)

5.3 Calculate the following dimensions for a parallel key suitable for a 75 mm diameter shaft that must be used in the driveshaft of a crane:

5.3.1 Width (2)

5.3.2 Thickness (2)

5.3.3 Length (2)

5.4 State TWO disadvantages of down-cut milling. (2)

[18]

QUESTION 6: TERMINOLOGY (INDEXING) (SPECIFIC)

6.1 Pieter is a machinist and is tasked to cut a spur gear with a module of 1,5 and 200 teeth.

Calculate the following:

6.1.1 Pitch-circle diameter (2)

6.1.2 Dedendum (2)

6.1.3 Outside diameter (2)

6.1.4 Working depth (2)

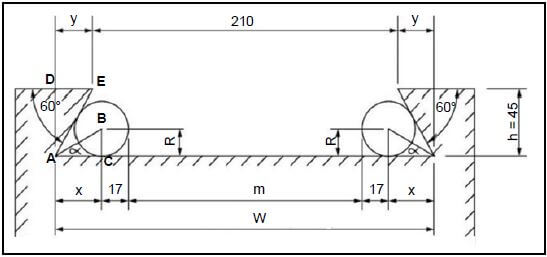

6.2 FIGURE 6.2 below shows an external dovetail.

FIGURE 6.2

Calculate the following:

6.2.1 Maximum width distance of the dovetail (W) (6)

6.2.2 Measurement between the precision rollers (m) (6)

6.3 Mr Naidoo is required to cut a spur gear with 137 teeth for a client. The dividing head he is using has a ratio of 40 : 1.

HINT: Use A = 140 divisions for the simple indexing.

6.3.1 Calculate the indexing that is needed. (3)

6.3.2 Calculate the change gears that are needed. (5)

[28]

QUESTION 7: TOOLS AND EQUIPMENT (SPECIFIC)

7.1 State TWO functions of a moment and force tester. (2)

7.2 Name TWO hardness testers to be used to test the hardness of steel. (2)

7.3 Which precision measuring instrument is used to measure the depth of a hole? (1)

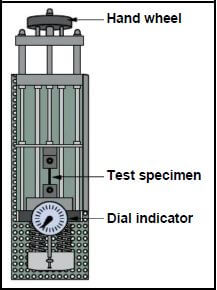

7.4 Identify the type of tester shown in FIGURE 7.4 below.

FIGURE 7.4 (1)

7.5 State THREE ways to measure the hardness of a metal. (3)

7.6 Calculate the required height of the screw thread that is needed to manufacture a M16 x 2 bolt. (2)

7.7 Name ONE precision measuring instrument that can be used to measure the outside diameter, inside diameter and the depth on a work piece. (1)

7.8 Why are interchangeable rods used in depth micrometers? (1)

[13]

QUESTION 8: FORCES (SPECIFIC)

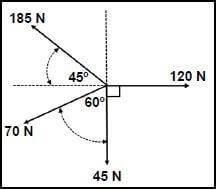

8.1 FIGURE 8.1 below shows a system of four forces acting onto the same point. Make use of calculations to determine the magnitude and direction of the resultant for this system of forces.

HINT: Draw and complete the diagram for the forces shown in FIGURE 8.1. To assist you, show ALL the horizontal and vertical components before you do the calculation.

FIGURE 8.1 (15)

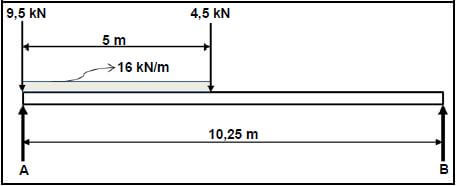

8.2 FIGURE 8.2 below indicates a uniform beam that is supported by two vertical supports, A and B. Two vertical point loads and a uniformly distributed load of 16 kN/m are exerted onto the beam.

FIGURE 8.2

Calculate the following:

8.2.1 The point load representing the uniformly distributed load (2)

8.2.2 The magnitude of the reaction at support A (3)

8.2.3 The magnitude of the reaction at support B (3)

8.3 A tensile force of 90 kN is applied to a solid mild steel shaft. The resistance area of the shaft is 6,17 x 10-3m2. After the force was applied on the shaft, the original length changed by a distance of 0,012 mm.

Calculate the following:

8.3.1 The stress in the material in MPa (2)

8.3.2 The diameter of the mild steel shaft in mm (5)

8.3.3 The original length of the shaft in mm if the strain is 1,64 x 10-3 (3)

[33]

QUESTION 9: MAINTENANCE (SPECIFIC)

9.1 Preventative maintenance of mechanical drive systems is divided into two subgroups. Name the TWO subgroups. (2)

9.2 State THREE preventative maintenance procedures to ensure that a gear drive performs well. (3)

9.3 What is the purpose of a jockey pulley used in belt drives? (1)

9.4 State TWO properties of EACH of the following materials:

9.4.1 Teflon (2)

9.4.2 Nylon (2)

9.4.3 Vesconite (2)

9.5 Name ONE product that can be made from the following composites:

9.5.1 Polyvinyl chloride (PVC) (1)

9.5.2 Glass fibre (1)

9.6 Explain the difference between thermoplastic and thermo-hardened composites. (4)

[18]

QUESTION 10: JOINING METHODS (SPECIFIC)

10.1 Name THREE different screw thread profiles found in the machine workshop. (3)

10.2 A two-start square thread has to be cut on a lathe. The lead of square thread is 36 mm and the crest diameter is 80 mm. The clearance angle must be 3°.

Calculate the following:

10.2.1 Pitch diameter (4)

10.2.2 Helix angle (4)

10.2.3 Leading angle (2)

10.2.4 Following angle (2)

10.3 State THREE advantages of a bolt with multiple screw threads. (3)

[18]

QUESTION 11: SYSTEMS AND CONTROL (DRIVE SYSTEMS) (SPECIFIC)

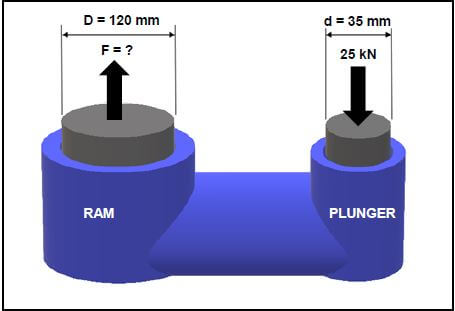

11.1 An artisan was instructed to design a hydraulic system that will be used to press bearings. The force that is exerted onto the plunger is 25 kN. The specifications of the system are shown diagrammatically in FIGURE 11.1 below.

FIGURE 11.1

Calculate the following:

11.1.1 The fluid pressure in the hydraulic system in MPa (4)

11.1.2 The magnitude of the force that will be exerted onto the bearing by the ram (5)

11.2 State ONE function of a hydraulic reservoir. (1)

11.3 Give TWO reasons why pneumatic systems are very efficient. (2)

11.4 State TWO uses of pneumatic systems. (2)

11.5 A pulley with a diameter of 800 mm is mounted on a shaft of a washing machine. The washing machine is driven from a pulley with a diameter of 600 mm which rotates at a speed of 7,2 r/s. The tensile force in the tight side of the belt is 300 N. The ratio between the tensile force in the tight side and slack side is 2,5 : 1. (Ignore belt thickness.)

Determine the following by means of calculations:

11.5.1 The rotational frequency of the pulley on the washing machine in r/s (3)

11.5.2 The power that can be transmitted in kW (4)

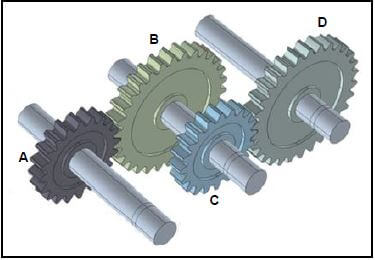

11.6 FIGURE 11.6 below shows a gear drive system. Driver gear A on the shaft of the motor has 30 teeth and meshes with gear B with 40 teeth on the counter shaft. On the counter shaft is another driver gear, C, with 20 teeth that mesh with gear D with 60 teeth on the output shaft.

FIGURE 11.6

Calculate the following:

11.6.1 The rotation frequency of the output shaft if the motor rotates at 2 300 r/min (4)

11.6.2 The ratio between the input shaft and the output shaft of the system. (3)

[28]

TOTAL: 200

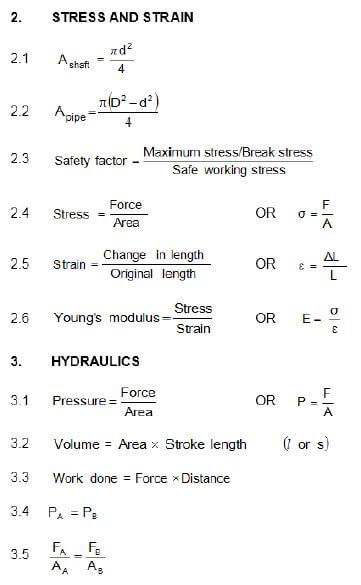

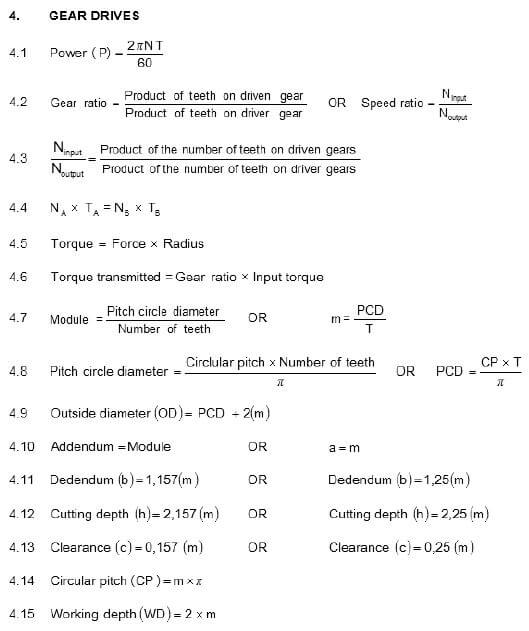

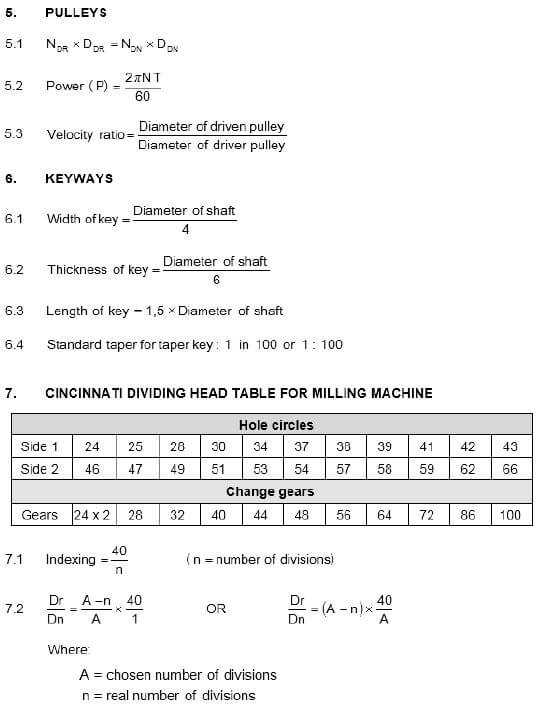

FORMULA SHEET FOR MECHANICAL TECHNOLOGY: