CIVIL TECHNOLOGY(WOODWORKING) GRADE 12 MEMORANDUM - NSC PAST PAPERS AND MEMOS NOVEMBER 2021

Share via Whatsapp Join our WhatsApp Group Join our Telegram GroupINSTRUCTIONS FOR THE MARKERS

- Markers should:

- Familiarise themselves with the question and answer before evaluating the responses of candidates.

- Always interpret the responses of the candidates within the context of the question.

- Consider any relevant and acceptable answer during pre-marking, but should strictly adhere to the answers after finalisation of the marking guidelines.

- There are two approaches to answering questions, these are (1) to describe and (2) to explain.

- If a candidate is required to explain e.g. a process in 4 steps, only the first 4 responses should be considered.

- If, however a candidate is required to e.g. explain or describe how to transfer heights from one point to another using a transparent pipe level we need to consider that candidates may write a long description not necessarily well organised as an intellectual response may do. In this case the marker needs to evaluate the complete statement to judge if the candidate explained the required outcome satisfactorily and allocate marks on merit. The marker should apply his/her professional judgement with these types of questions.

- Mark what the candidate wrote and do not award marks for answers that the marker thinks the candidate meant with what was written.

- Indicate the tick or cross right at the position where the mark needs to be awarded or where the candidate made the error.

- Accept the letter corresponding with the correct answer as well as the answer written in full in multiple-choice questions.

- Accept incorrect spelling in one-word answers unless the spelling changes the meaning of the answer.

- For calculations:

- A mark is only awarded if the correct unit is written next to the answer.

- If TWO marks are awarded, ONE mark is awarded for the answer and ONE mark for the correct unit.

- Where the candidate made a principle error, e.g. use an incorrect method to calculate the answer, marks will be awarded for the correct values used in the calculation. No marks will be awarded for the answer of the incorrect method that was followed.

- Where an incorrect answer could be carried over to the next step, the first answer will be deemed incorrect. However, should the incorrect answer be carried over correctly, the marker has to recalculate the values, using the incorrect answer from the first calculation. If correctly used, the candidate should receive the full marks for subsequent calculations.

- Markers should consider when and where a candidate has rounded off in a calculation, as well as the subsequent effect it has on the final answer obtained. The mark for calculations should therefore be awarded on merit.

- Alternative methods of calculations must be considered, provided that the correct answer is obtained.

- When marking drawings:

- The member for which the mark should be awarded should be drawn correctly in the correct position to receive a mark.

A member incorrectly drawn but wrongfully repeated in another position will be awarded the mark for the repeated incorrect member, provided that the marking guidelines provide for TWO or more marks for that member (positive marking).

Marks can only be awarded for a label if the label is correctly indicating the correct member.

Scale drawings should always be marked using an appropriate mask.

When a candidate drew the wrong drawing, e.g.:

A horizontal sectional view instead of a vertical sectional view, no marks will be allocated to the drawing as the candidate did not respond to the expected outcome.

An orthographic view instead of a sectional view, no marks will be allocated to the drawing as the candidate did not respond to the expected outcome.

An orthographic view instead of an isometric view, no marks will be allocated to the drawing as the candidate did not respond to the expected outcome.

- The member for which the mark should be awarded should be drawn correctly in the correct position to receive a mark.

QUESTION 1: OHSA, SAFETY, MATERIALS, TOOLS, EQUIPMENT AND JOINING (GENERIC)

1.1

1.1.1 Galvanising (1)

1.1.2 Paint (1)

1.1.3 Electroplating (1)

1.1.4 Curing (1)

1.1.5 Powder coating (1)

1.2

1.2.1 Scaffolding must be:

- Properly propped against displacement.

- Able to carry the mass or load.

- Securely and effectively braced to ensure stability/Stable.

- Secured at suitable vertical and horizontal distances to the structure.

- Free of defects/sharp edges.

- Constructed so that it has a safety factor of at least two.

- Levelled.

- Inspected regularly.

ANY TWO OF THE ABOVE (2)

1.2.2 Toe-board/Kickboard (1)

1.2.3 When working on scaffolding:

- Wear a safety harness/safety equipment/PPE.

- Do not throw any materials from a scaffold.

- Do not throw any tools from a scaffold.

- Never jump from a scaffold.

- Do not overload a scaffold.

- Remove or cover sharp edges or corners of a scaffold.

- Scaffolds should be kept free of waste/obstructions.

ANY TWO OF THE ABOVE (2)

1.3 To remove waste:

- Use a chute/pipe chute

- Use a conveyor belt/ramp

- Use a bucket with a rope/pulley system

- Use a forklift/mobi-lift/TLB/crane with a bucket/builders’ hoist

ANY TWO OF THE ABOVE (2)

1.4 Safe use of trestle scaffolds:

- Scaffolds should be soundly constructed of solid material.

- All precautionary measures should be taken to prevent the unexpected spreading of its supporting legs when in use.

- Trestles should not exceed a height of 3 m.

- Trestles scaffolds should not consist of more than two tiers.

ANY TWO OF THE ABOVE (2)

1.5 Hoisting materials and equipment in a builder’s hoist:

- Materials and equipment should be firmly stacked.

- Materials and equipment should be correctly stacked.

- Materials and equipment should be properly secured.

- Gates must be shut when in use.

- Overhead protection must be provided.

- Qualified person must operate the builders' hoist.

- Emergency brake mechanism must be installed.

- Not exceed the working capacity of the hoist/Not overload the hoist.

- Safety measures must be displayed inside the cage.

ANY ONE OF THE ABOVE (1)

1.6

- Drill a hole through the two metal plates.

- Insert the bolt into the drilled holes.

- Fasten the two plates with a bolt and nut. (3)

1.7 Used to locate:

- Materials behind walls.

- Materials in ceilings.

- Materials under floors.

- Steel bars

- Copper pipes

- Ferrous metals

- Non-ferrous metals

- Electrical wiring

- Services

- Wood/Wooden/metal studs behind walls.

- The distance to and from an object.

ANY ONE OF THE ABOVE (1)

Care

Protect the multi-detector against: - Moisture/Water/Corrosion

- Direct sunlight/heat

- Extreme temperature changes

- Bumps/Falling

- Damage caused by the release of acid from the battery

ANY ONE OF THE ABOVE (1)

[20]

QUESTION 2: GRAPHICS AS MEANS OF COMMUNICATION (GENERIC)

| NO. | QUESTIONS | ANSWER | MARKS |

| 1 | Identify the scale you will use for the site plan and the floor plan respectively. | 1 : 200 1 : 100 | 2 |

| 2 | Who is responsible to verify all dimensions and levels on site before commencing work? | Contractors | 1 |

| 3 | What type of fencing does the architect recommend for the new dwelling? | Palisade fencing/Palisade | 1 |

| 4 | State the colour that you would use to indicate the new dwelling on the site plan. | Red | 1 |

| 5 | Identify number 1. | Boundary line | 1 |

| 6 | Identify number 2. | Building line | 1 |

| 7 | Identify number 3. | Electricity meter/Watt meter | 1 |

| 8 | Identify number 4. | Entrance/Exit/Driveway | 1 |

| 9 | Identify number 5. | Water storage tank/Water tank

| 1 |

| 10 | Identify number 6. | Pavement/Walkway/Sidewalk | 1 |

| 11 | Identify number 7. | North point/North symbol/North sign/North direction | 1 |

| 12. | Identify number 8. | Municipal connection/Municipal manhole/Main sewer connection | 1 |

| 13 | Identify number 9. | Manhole | 1 |

| 14 | Determine the distance between number 2 and the new dwelling on the eastern side of the building. | 4 000 mm/4 m | 1 |

| 15 | Deduce the plot number of the new dwelling from FIGURE A. | Plot 31 | 1 |

| 16 | Which elevation is the closest to Loerie Street? | South elevation/South | 1 |

| 17 | What is the plot number of the property on the western side of the dwelling? | Plot 35 | 1 |

| 18 | Deduce TWO faults on FIGURE B. | No window in the dining room 110 mm of outside wall is incorrect/ Internal wall thickness Light switch in bathroom is in wrong place 220 mm inside wall in room A is incorrect/External wall thickness No step at the kitchen door No door in dining room/living room/door opening No arch indicated at dining room/living room Floor covering not indicated in rooms No socket outlets/plugs in rooms No hatching of floor plan No ceiling light in passage No dashed/hidden detail lines shown between living/dining/kitchen to indicate the arch ANY TWO OF THE ABOVE | 2 |

| 19 | Which natural feature is indicated on the site plan? | Trees/Shrubs | 1 |

| 20 | What is wrong with the electrical installation in the bathroom in FIGURE B? | The light switch is fitted on the inside of the bathroom/Switch is incorrectly placed. | 1 |

| 21 | Identify number 10. | Ramp | 1 |

| 22 | Identify number 11. | Sink–double bowl/ Double bowl sink/Double sink | 1 |

| 23 | Identify number 12. | Two-way switch | 1 |

| 24 | Identify number 13. | One-way switch single-pole/One-way switch/Single-pole switch | 1 |

| 25 | Draw the symbol of a socket outlet. |  | 2 |

| 26 | Draw the symbol for a shower. |  | 2 |

| 27 | Draw the symbol for a wall-mounted light. | 2 | |

| 28 | Recommend TWO uses for ROOM A. | Dressing room/Walk-in closet En-suite/Bathroom Gym/Gymnasium Study/Office Store/Rest/Baby/Play/Games/ Guest/TV room Laundry ANY TWO OF THE ABOVE | 2 |

| 29 | Calculate the omitted horizontal dimension on the site plan. Give your answer in mm. Show ALL calculations. | 24 500 – 5 000 – 9 000 – 3 000 – 5 000 = 2 500 mm ANY OTHER CALCULATION METHOD TO ARRIVE AT THE ANSWER | 6 |

| 40 |

QUESTION 3: CUPBOARDS, CASEMENTS, WALL-PANELING AND QUANTITIES (SPECIFIC)

3.1

3.1.1 Bottom rail of fanlight (1)

3.1.2 Transom (1)

3.1.3 Wood/Wooden (glazing) bead/Quadrant/Quarter round (1)

3.1.4 Reason for moulding:

- To enhance appearance/Decorative appearance

- To provide a good finish

ANY ONE OF THE ABOVE (1)

3.1.5 Small window above door/window (1)

3.1.6 To prevent water/moist from entering:

- The house through the casement

- The casement

ANY ONE OF THE ABOVE (1)

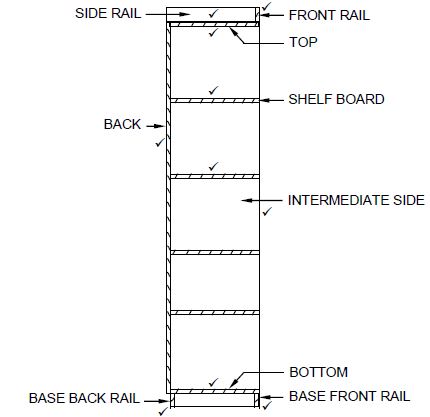

| 3.2.1 | Member | Quantity | Unit | Length | Width | Thickness | Material |

| Side | 2 | mm | 2400 | 550 | 16 | Melamine | |

| Bottom | 1 | mm | 1068 | 550 | 16 | Melamine | |

| Top | 1 | mm | 1068 | 550 | 16 | Melamine | |

| Base front rail | 1 | mm | 1068 | 80 | 16 | Melamine | |

| Shelf board | 4 | mm | 550 | 526 | 16 | Melamine | |

| Intermediate side | 1 | mm | 2368 | 550 | 16 | Melamine | |

| Back | 1 | mm | 2400 | 1100 | 16 | Melamine |

(7)

3.2.2

HATCHING

| ASSESSMENT CRITERIA | MARK |

| Correctness of drawing: | |

| Side rail | 1 |

| Front rail | 1 |

| Top | 1 |

| Shelve boards | 2 |

| Intermediate side | 1 |

| Bottom | 1 |

| Back/Back rail | 1 |

| Base front rail | 1 |

| Base back rail | 1 |

| Hatching | 1 |

| TOTAL: | 11 |

(11)

BASE BACK RAIL

INTERMEDIATE SIDE

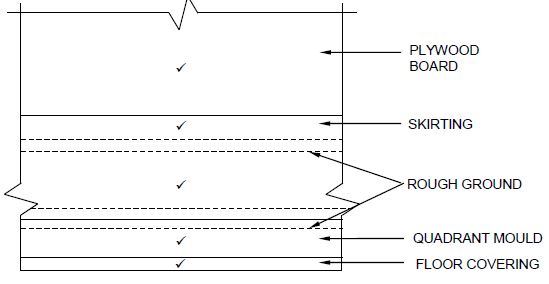

3.3

| ASSESSMENT CRITERIA | MARK |

| Correctness of drawing: | |

| Plywood board | 1 |

| Skirting | 1 |

| Rough ground | 1 |

| Quadrant mould | 1 |

| Floor covering | 1 |

| Application of scale | 1 |

| TOTAL: | 6 |

DRAWING NOT TO SCALE (6)

USE A MASK TO MARK THIS QUESTION [30]

QUESTION 4: ROOFS, CEILINGS, TOOLS, EQUIPMENT AND MATERIALS (SPECIFIC)

4.1

4.1.1 F (1)

4.1.2 H/B (1)

4.1.3 I (1)

4.1.4 K (1)

4.1.5 B (1)

4.1.6 J (1)

4.1.7 A (1)

4.1.8 E (1)

4.2 Both machines must be:

- Switched on before coming into contact with the work piece.

- Switched off when lifting the machine from the work piece. (2)

4.3 Safe handling of the square chisel with its drill (mortising attachment):

- The square chisel with its drill bit must be securely tightened.

- Ensure a clearance of 1 mm between the tip of the bit and the cutting edge of the chisel.

- Never use a blunt chisel and drill bit.

ANY TWO OF THE ABOVE (2)

4.4 When working with a belt sander and router:

- Place both hands on the handles when operating these machines.

- Keep your hands away from moving parts.

ANY ONE OF THE ABOVE (1)

4.5

4.5.1 Metal T-strip (1)

4.5.2 Tie beam (1)

4.5.3 Materials for trapdoor:

- Gypsum board/Rhino board

- Timber/Plywood/Masonite/Hardboard

- Block board

- Metal

- Fibre-cement/Nu-tech

- PVC/Plastic

- ISO board

ANY THREE OF THE ABOVE (3)

4.5.4 Aluminium is popular because:

- It is light in weight.

- It provides an aesthetic finish/No need to paint it.

- It is durable/strong/corrosion free.

- It is easy to fix against brandering.

ANY TWO OF THE ABOVE (2)

4.6

- Lean-to roofs/Flat roofs

- Couple roofs (2)

4.7 King post roof: Tie beam

Collar-tie roof: Collar beam (2)

4.8 Ridge beam (1)

4.9 To secure/fix the rafters to the ridge beam. (1)

4.10 The number of the queen posts will be determined by the:

- Length of the tie-beam.

- Span of the truss/building.

ANY ONE OF THE ABOVE (1)

4.11 Components used:

- Soffit hanger

- Bearer

- Soffit board

- Quarter-round moulding

- Ceiling board/Slats

- Fascia board

ANY TWO OF THE ABOVE (2)

4.12

2

4

6

3

5

1

MARK STRICTLY ACCORDING TO SEQUENCE (6)

4.13 Type of varnish finish:

- Glossy

- Matt

- Satin/Sheen

ANY TWO OF THE ABOVE (2)

4.14 Sanding sealer can be applied with a:

- Spray gun

- Brush

ANY ONE OF THE ABOVE

Wax can be applied with a: - Sponge

- Shoe brush/Brush

- Cloth

ANY ONE OF THE ABOVE (2)

4.15 Waxed surfaces tend to make:

- White spots on the surface

- White rings on the surface

ANY ONE OF THE ABOVE (1)

[40]

QUESTION 5: CENTERING, FORMWORK, SHORING AND GRAPHICS AS MEANS OF COMMUNICATION (SPECIFIC)

5.1

5.1.1 C (1)

5.1.2 A (1)

5.1.3 D (1)

5.1.4 A (1)

5.1.5 B (1)

5.2

5.2.1

- Segmental arch/Oval/Elliptical arch (1)

- Semi-circular arch/Half round arch (1)

5.2.2 Closed laggings (1)

5.2.3 450 mm (1)

5.2.4 Ribs can be secured by:

- Ties

- Struts

ANY ONE OF THE ABOVE (1)

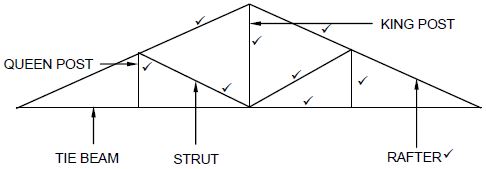

5.3

| ASSESSMENT CRITERIA | MARK |

| Correctness of drawing: | |

| Rafters | 2 |

| King post | 1 |

| Queen posts | 2 |

| Struts | 2 |

| Tie beam | 1 |

| Label (Any ONE) | 1 |

| TOTAL: | 9 |

(9)

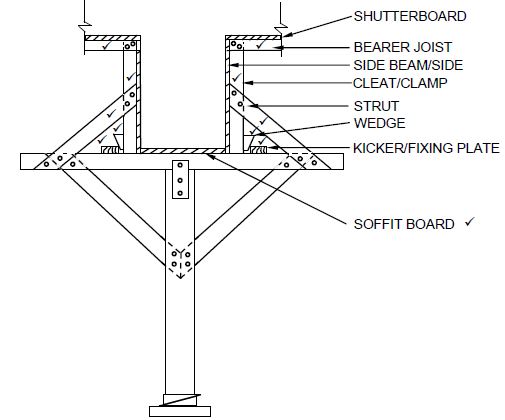

5.4

| ASSESSMENT CRITERIA | MARK |

| Correctness of drawing: | |

| Bearer joists | 2 |

| Clamps/Cleats | 2 |

| Struts | 2 |

| Wedges | 2 |

| Kicker/Fixing plates | 2 |

| Label (Any ONE) | 2 |

| TOTAL: | 11 |

(11)

[30]

QUESTION 6: SUSPENDED FLOORS, STAIRCASES, IRONMONGERY, DOORS AND JOINING (SPECIFIC)

6.1

6.1.1 Night latch/lock (1)

6.1.2 Mortise lock (1)

6.1.3 Rim lock (1)

6.1.4 Straight cupboard lock (1)

6.2

6.2.1 Between the leg and the rail. (2)

6.2.2

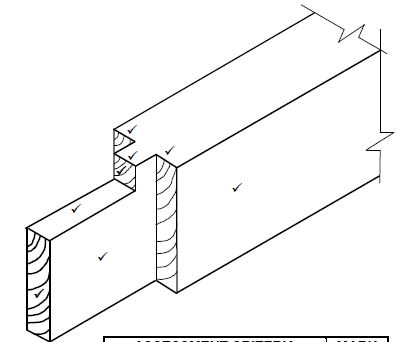

| ASSESSMENT CRITERIA | MARK |

| Correctness of drawing: | |

| Rail | 1 |

| Haunch | 4 |

| Tenon | 3 |

| TOTAL: | 8 |

(8)

6.3

(3)

6.4

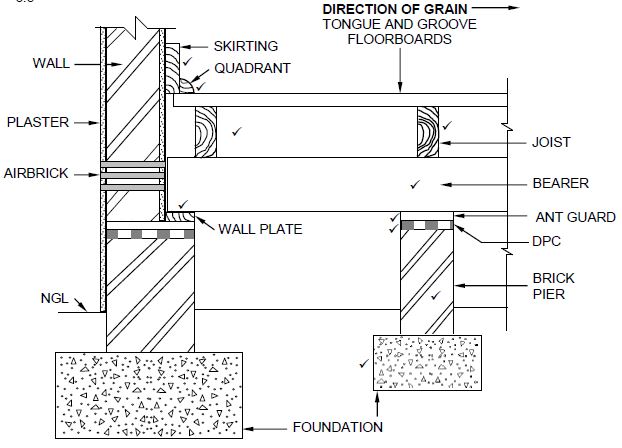

6.5

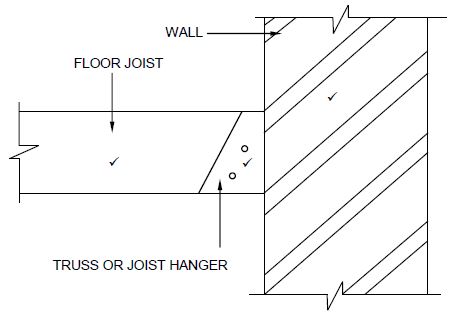

| ASSESSMENT CRITERIA | MARK |

| Correctness of drawing: | |

| Closure of opening between wall and floorboards | 2 |

| Members supporting flooring boards: | |

| Wall plate | 1 |

| Bearer | 1 |

| Joists | 2 |

| One-brick pier with foundation | 2 |

| Prevention of termites and moisture at the pier | 2 |

| TOTAL: | 10 |

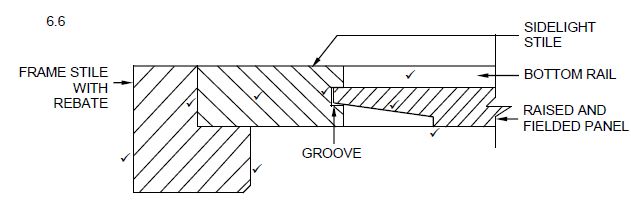

| ASSESSMENT CRITERIA | MARK |

| Correctness of drawing: | |

| Frame stile with rebate | 2 |

| Sidelight stile | 1 |

| Groove/Clearance for expansion | 1 |

| Bottom rail | 1 |

| Raised and fielded panel | 2 |

| Hatching | 1 |

| TOTAL: | 8 |

(8)

[40]

TOTAL: 200