MECHANICAL TECHNOLOGY (AUTOMOTIVE) GRADE 12 QUESTIONS - NSC EXAMS PAST PAPERS AND MEMOS NOVEMBER 2020

Share via Whatsapp Join our WhatsApp Group Join our Telegram GroupMECHANICAL TECHNOLOGY: AUTOMOTIVE

GRADE 12

NOVEMBER 2020

NATIONAL SENIOR CERTIFICATE

INSTRUCTIONS AND INFORMATION

- Write your centre number and examination number in the spaces provided on the ANSWER BOOK.

- Read ALL the questions carefully.

- Answer ALL the questions.

- Number the answers correctly according to the numbering system used in this question paper.

- Start EACH question on a NEW page.

- Show ALL calculations and units. Round off final answers to TWO decimal places.

- Candidates may use non-programmable scientific calculators and drawing instruments.

- The value of gravitational acceleration should be taken as 10 m/s2.

- All dimensions are in millimetres, unless stated otherwise in the question.

- Write neatly and legibly.

- A formula sheet is attached at the end of the question paper.

- Use the criteria below to assist you in managing your time.

| QUESTION | CONTENT | MARKS | TIME in minutes |

| GENERIC | |||

| 1 | Multiple-choice Questions | 6 | 6 |

| 2 | Safety | 10 | 10 |

| 3 | Materials | 14 | 14 |

| SPECIFIC | |||

| 4 | Multiple-choice Questions | 14 | 10 |

| 5 | Tools and Equipment | 23 | 20 |

| 6 | Engines | 28 | 25 |

| 7 | Forces | 32 | 25 |

| 8 | Maintenance | 33 | 20 |

| 9 | Systems and Control (Automatic Gearbox) | 18 | 20 |

| 10 | Systems and Control (Axles, Steering Geometry and Electronics) | 32 | 30 |

| TOTAL | 200 | 180 |

QUESTION 1: MULTIPLE-CHOICE QUESTIONS (GENERIC)

Various options are provided as possible answers to the following questions. Choose the answer and write only the letter (A–D) next to the question numbers (1.1 to 1.6) in the ANSWER BOOK, e.g. 1.7 A.

1.1 What is the purpose of the Occupational Health and Safety Act, 1993 (Act 85 of 1993) with regard to HIV/Aids awareness?

- The Act on safety states that all employers must make sure that the workplace is safe and that employees are not at risk of becoming infected with HIV at work.

- The Act contains common guidelines on how employers, employees and trade unions should respond to HIV in the workplace.

- Employers may not demote or promote an employee based on his/her HIV status.

- Employers cannot simply dismiss a person who has been infected with HIV. (1)

1.2 Which ONE of the following pieces of personal protective equipment is applicable when using a drill press?

- Hard hat

- Apron

- Surgical gloves

- Safety goggles (1)

1.3 Which statement describes the placing of the machines in a product layout?

- The machines are arranged in the sequence in which operations are carried out.

- The machines are arranged according to the worker's skills.

- The machines are grouped according to their types of operation.

- The machines are arranged according to the products. (1)

1.4 Which heat-treatment process is used to give steel a high resistance against wear?

- Annealing

- Tempering

- Hardening

- Normalising (1)

1.5 The purpose of tempering steel is to …

- harden it.

- increase the toughness.

- soften it.

- cool it down. (1)

1.6 Which test uses an indenter to determine the hardness of steel?

- Sound test

- Rockwell test

- Bending test

- Machining test (1)

[6]

QUESTION 2: SAFETY (GENERIC)

2.1 What safety rule must be adhered to after work procedures on a machine have been completed? (1)

2.2 State TWO safety precautions that must be adhered to after the horizontal band saw has been switched on. (2)

2.3 Give TWO reasons why surgical gloves must be worn when treating a co-worker with open wounds. (2)

2.4 State TWO pieces of personal protective equipment (PPE) which must be worn during arc welding. (2)

2.5 Describe the responsibility of an employer regarding the safety and health of the employees in the workplace. (2)

2.6 Who is responsible for administering first aid to an injured person at the workplace? (1)

[10]

QUESTION 3: MATERIALS (GENERIC)

3.1 Explain how you will conduct the following tests to identify various metals:

3.1.1 Sound test (2)

3.1.2 File test (2)

3.2 What is the purpose of the heat treatment of steel? (2)

3.3 What is the purpose of the case hardening of steel? (2)

3.4 Describe the tempering process of steel. (3)

3.5 Name the THREE factors which need to be taken into consideration when heat treatment of steel is done. (3)

[14]

QUESTION 4: MULTIPLE-CHOICE QUESTIONS (SPECIFIC)

Various options are provided as possible answers to the following questions. Choose the answer and write only the letter (A–D) next to the question numbers (4.1 to 4.14) in the ANSWER BOOK, e.g. 4.15 A.

4.1 What is the function of the computerised diagnostic scanner used on a motor vehicle?

- To scan whether the engine leaks gases from the cylinder during the induction stroke

- To scan whether the engine leaks gases from the cylinder during the power stroke

- To scan all systems on the vehicle and to adjust different sensors

- To scan the engine of the vehicle and to adjust all engine components (1)

4.2 Which ONE of the following pieces of equipment is used to test the crankcase gases?

- Torsion tester

- Gas analysing tester

- Tensile tester

- Combustion tester (1)

4.3 What is the volumetric efficiency of a centrifugal blower?

- The ability to fill the cylinder with air above the barometric pressure

- The ability to fill the cylinder with air below the barometric pressure

- The ability to fill the cylinder with air below the atmospheric pressure

- The ability to fill the cylinder with air above the atmospheric pressure (1)

4.4 Which ONE of the following is the cause of crankshaft vibrations?

- Taper of the crankshaft journal

- Ovality of the crankshaft journal

- The reciprocating mass is not balanced

- The reciprocating mass is balanced (1)

4.5 Which ONE of the following is an important method used to increase the compression ratio of an engine?

- Fit a thinner gasket between the cylinder block and the cylinder head.

- Fit the pistons with suitable lower crowns.

- Fit a thicker gasket between the cylinder block and the cylinder head.

- Fit a crankshaft with a shorter stroke. (1)

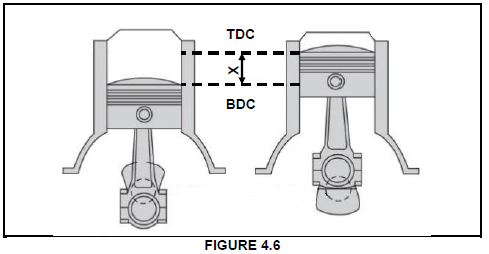

4.6 What does the symbol X in FIGURE 4.6 indicate?

- Compression length

- Stroke length

- Piston length

- Cylinder length (1)

4.7 What will the brake power of the engine be if the engine delivers a mechanical efficiency of 83,34% with 60 kW indicated power?

- 50 W

- 1,5 N.m

- 1,2 N.m

- 50 kW (1)

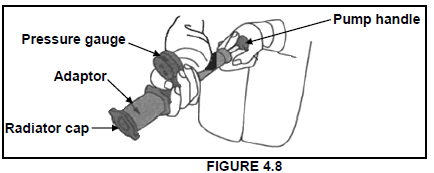

4.8 What type of test is conducted with the equipment shown in FIGURE 4.8?

- Testing for water leaks

- Testing the radiator

- Testing for fuel leaks

- Testing the radiator cap (1)

4.9 Which ONE of the following is an advantage of an electrical fuel pump in a motor vehicle?

- High operating noise

- Low acceleration

- Low operation noise

- Large engine capacity (1)

4.10 What type of tyre wear is shown in FIGURE 4.10?

- Feathered-edged wear

- Camber-edged wear

- Caster-edged wear

- Kingpin-edged wear (1)

4.11 What type of drive is the outcome when the planet carrier is locked for a double epicyclic gear?

- First or low gear

- Second or intermediate gear

- Third or top gear

- Reverse gear (1)

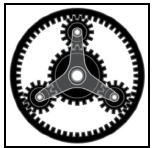

4.12 Which gear system is shown in FIGURE 4.12?

- Automatic gear system

- Single epicyclic gear system

- Double epicyclic gear system

- Overdrive gear system (1)

4.13 What will be the speed of a driven gear if the gear ratio of a gear train is given as 5 : 1 and the drive gear rotates at 500 r/min?

- 2 500 r/min

- 500 r/min

- 100 r/min

- 1 500 r/min (1)

4.14 Which ONE of the following is the function of the rotor assembly in an alternator charging system?

- Provides the core that concentrates the negative lines

- Provides the core into which voltage is induced

- Provides a rotary electro-magnet

- Provides a movable connection to pass current (1)

[14]

QUESTION 5: TOOLS AND EQUIPMENT (SPECIFIC)

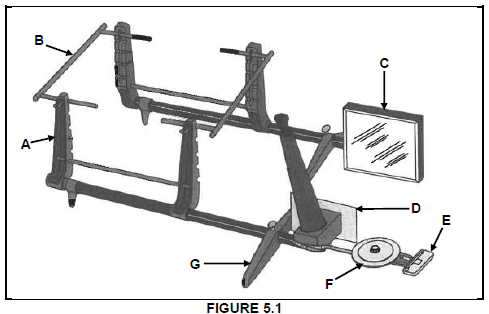

5.1 FIGURE 5.1 below shows a periscope optical alignment gauge. Answer the questions that follow.

5.1.1 Label A–G of the gauge shown in FIGURE 5.1. (7)

5.1.2 What is the function of the optical alignment gauge shown in FIGURE 5.1? (1)

5.1.3 Give the set-up procedure, in the correct sequence, of how to calibrate the optical alignment gauge. (5)

5.2 Explain how to correct static imbalance of a wheel and tyre assembly. (2)

5.3 State THREE engine parameters which can be monitored when using the computerised diagnostic scanner. (3)

5.4 What will be the result if there is a leak in the exhaust manifold or vacuum system of a motor vehicle when a gas analyser is used? (2)

5.5 State THREE conditions that can be revealed by a compression test on an internal combustion engine. (3)

[23]

QUESTION 6: ENGINES (SPECIFIC)

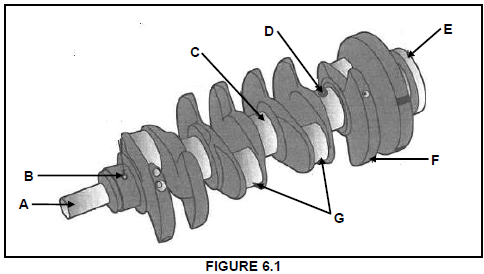

6.1 FIGURE 6.1 below shows the crankshaft of a four-cylinder in-line engine. Answer the questions that follow.

6.1.1 What is the main function of the crankshaft shown in FIGURE 6.1? (2)

6.1.2 Label A–G, the parts of the crankshaft, as shown in FIGURE 6.1. (7)

6.1.3 State TWO firing orders of a four-cylinder in-line engine. (2)

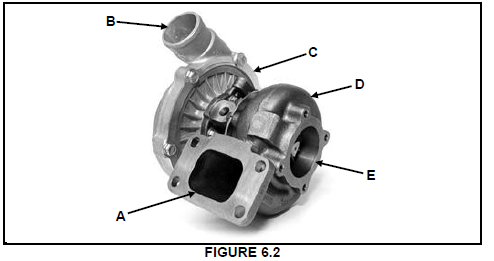

6.2 FIGURE 6.2 below shows a component that is fitted to an internal combustion engine to increase the power output. Answer the questions that follow.

6.2.1 Identify the component shown in FIGURE 6.2. (1)

6.2.2 Label A–E, the parts of the component in FIGURE 6.2. (5)

6.2.3 State the main function of the component in FIGURE 6.2. (1)

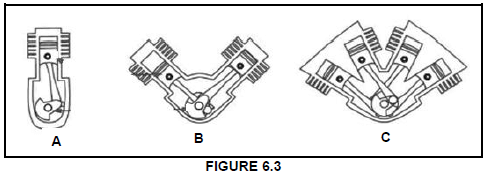

6.3 Identify the diffent types of engine layouts, as shown in FIGURE 6.3.

(3)

6.4 State THREE advantages of a vehicle fitted with both a supercharger and a turbocharger on its engine. (3)

6.5 State TWO disadvantages of a vehicle fitted with both a supercharger and a turbocharger on its engine. (2)

6.6 Why are the connecting rods and pistons manufactured as light as possible? (2)

[28]

QUESTION 7: FORCES (SPECIFIC)

7.1 Define the term indicated power of an internal combustion engine. (2)

7.2 State TWO methods to lower the compression ratio of an internal combustion engine. (2)

7.3 Name TWO types of dynamometers used to measure the power output of a motor vehicle. (2)

7.4 The bore and stroke of an internal combustion engine is 70 mm and 90 mm respectively. The compression ratio is 7,5 : 1.

Determine, by means of calculations:

7.4.1 The swept volume of a single cylinder in cm3 (3)

7.4.2 The original clearance volume of a single cylinder in cm3 (3)

7.4.3 The compression ratio is increased to 9,5 : 1. What will be the new diameter of the bore if the clearance volume remains unchanged? The answer must be in millimetres (mm). (6)

7.5 The data below was recorded during a test carried out on a four-cylinder four-stroke engine.

Brake arm length: 1 m Scale reading: 50 kg Stroke length: 140 mm Crankshaft revolutions: 4 500 r/min Mean effective pressure: 1 450 kPa Bore diameter: 110 mm Number of cylinders: 4

Determine, by means of calculations, the:

7.5.1 Torque (2)

7.5.2 Brake power in kW (4)

7.5.3 Indicated power in kW (6)

7.5.4 Mechanical efficiency (2)

[32]

QUESTION 8: MAINTENANCE (SPECIFIC)

8.1 State FOUR safety requirements to meet during the setting up of the gas analyser on an internal combustion engine. (4)

8.2 State THREE safety precautions to adhere to when setting up the fuel pressure tester on an internal combustion engine. (3)

8.3 Explain the difference between a compression test and a cylinder leakage test performed on an internal combustion engine. (4)

8.4 State FOUR safety precautions to adhere to while setting up a compression tester on an engine. (4)

8.5 TABLE 8.5 below shows information regarding the oil pressure test which is carried out on an internal combustion engine.

Complete TABLE 8.5 by adding another TWO possible causes and another TWO corrective measures at each fault.

Write only the answer next to the question numbers (8.5.1 to 8.5.8) in the ANSWER BOOK.

| FAULTS (DEFECTS) | POSSIBLE CAUSES | CORRECTIVE MEASURES |

| Oil pressure too low | Worn oil pump | Replace with new oil pump |

| 8.5.1 | 8.5.3 | |

| 8.5.2 | 8.5.4 | |

| Oil pressure too high | Dirty or contaminated oil | Change the oil |

| 8.5.5 | 8.5.7 | |

| 8.5.6 | 8.5.8 |

TABLE 8.5 (8)

[23]

QUESTION 9: SYSTEMS AND CONTROL (AUTOMATIC GEARBOX) (SPECIFIC)

9.1 State TWO functions of an automatic gearbox in a motor vehicle. (2)

9.2 State the function of the brake bands in the automatic gearbox. (1)

9.3 State TWO disadvantages of an automatic gearbox in a motor vehicle. (2)

9.4 State TWO advantages of a transmission control unit in an automatic transmission system. (2)

9.5 Name TWO components in an epicyclic gear train of an automatic gearbox, which engage and disengage the different components to obtain different gear ratios. (2)

9.6 Explain how the locking sequence of the epicyclic gear train is achieved. (2)

9.7 What is the main purpose of the control valve body in an automatic gearbox? (2)

9.8 Explain the operation of the torque converter in an automatic transmission. (5)

[18]

QUESTION 10: SYSTEMS AND CONTROL (AXLES, STEERING GEOMETRY AND ELECTRONICS) (SPECIFIC)

10.1 Define static balance of a wheel and tyre assembly. (2)

10.2 State THREE factors to be checked before the wheel balancing process can be performed. (3)

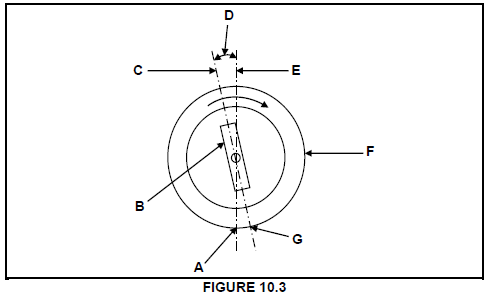

10.3 FIGURE 10.3 below shows a wheel alignment angle. Answer the questions that follow.

10.3.1 Identify the wheel alignment angle in FIGURE 10.3. (2)

10.3.2 Label parts A–G in FIGURE 10.3. (7)

10.3.3 Define the positive castor angle. (2)

10.4 Explain the function of the Ackermann principle. (2)

10.5 Describe the purpose of the catalytic converter on the exhaust system of a motor vehicle. (1)

10.6 State TWO requirements that must be met for a catalytic converter to function effectively. (2)

10.7 Explain how the lambda oxygen sensor operates. (5)

10.8 State FOUR precautionary measures to be taken when working on an alternator charging system. (4)

10.9 Name TWO types of electric fuel pumps. (2)

[32]

TOTAL: 200

FORMULA SHEET FOR MECHANICAL TECHNOLOGY (AUTOMOTIVE)

- Force = m x a

where m = mass

a = acceleration - Work = force x distance( F x d)

- Power = force x distance

time - Torque = force x radius

- Indicated power = P x L x A x N x n

where P mean effective pressure

L length of stroke

A area of piston crown

N number of power strokes per second

n number of cylinders - Brake power = 2 x π x N x T

where N = revolutions per second

T = torque - Brake power (Prony brake) F x 2 x π x R x N

where F force

R length of brake arm

N revolutions per second - Mechanical efficiency = brake power x 100%

indicated power - Compression ratio= swept volume + clearance volume

clearance volume - where swept volume = π x D2 x L

4

where L = length of stroke

D = diameter of bore - Clearance volume = π x D2 x L

4

where D = diameter of bore

L = clearance - Gear ratio= product of the number of teeth of the driven gears

product of the number of teeth of the driver gears