Mechanical Technology: Automotive Memorandum - Grade 12 September 2021 Preparatory Exams

Share via Whatsapp Join our WhatsApp Group Join our Telegram GroupMEMORANDUM

QUESTION 1: MULTIPLE-CHOICE QUESTIONS (GENERIC)

1.1 C

1.2 D

1.3 D

1.4 A

1.5 B

1.6 B (6 x 1) [6]

QUESTION 2: SAFETY (GENERIC)

2.1 Safety Precautions

- Pressure gauges must be checked and tested regularly and adjusted or replaced if any malfunctioning occurs.

- Supporting pins that keep the platform at a desired height on the frame must be inspected for damage.

- Check the floor for oil and apparatus for leaks.

- The platform on which the workpiece rests must be rigid and square with the press cylinder. (Any 2 x 1) (2)

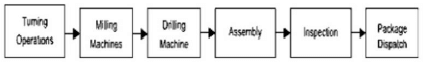

2.2 Product layout (2)

(2)

2.3 Perspex shield

- is installed to shield flying objects from harming the operator’s eye. (1)

2.4

2.4.1 Machine Identification

- Surface grinder (1)

2.4.2 Surface grinder parts label

- Workpiece

- Machine spindle

- Magnetic table

- Grinding wheel (4)

[10]

QUESTION 3: MATERIALS (GENERIC)

3.1 Heat treatment refers to heating and cooling of metals under controlled conditions in their solid state so as to change their properties. (2)

3.2 Heat treatment properties

| PROCESS | PROPERTY | |

| 3.2.1 | Hardening | Very hard, high tensile strength and brittle |

| 3.2.2 | Tempering | Tough, hard |

| 3.2.3 | Annealing | Soft, ductile, low tensile strength |

| 3.2.4 | Normalising | Tough and machinable |

(4)

3.3 Purpose of case-hardening

- Harden surface

- Provides high surface wear resistance

- Tough core (Any 2 x 1) (2)

3.4 Carbon effect

- Steel with low carbon content will not respond very much to the hardening process.(2)

3.5 Workshop tests on materials

- Sound test Bend test Filing test

- Machining test (Any 2 x 1) (2)

3.6 Reasons for annealing

- To relieve internal stresses that may have been set up during other processes.

- To soften them in order to facilitate the machining processes.

- To make material ductile.

- Refine their grain structures.

- Reduce brittleness (Any 2 x 1) (2)

[14]

QUESTION 4: MULTIPLE-CHOICE QUESTIONS (SPECIFIC)

4.1 B

4.2 C

4.3 C

4.4 A

4.5 B

4.6 C

4.7 D

4.8 D

4.9 D

4.10 A

4.11 C

4.12 B

4.13 B

4.14 A (14 x 1) [14]

QUESTION 5: TOOLS AND EQUIPMENT (SPECIFIC)

5.1

5.1.1 Equipment

- Compression tester (1)

5.1.2 Parts of a compression tester

- – Flexible pipe

- – Adaptors’ screw

- – Gauge

- – Relief valve (Release) (4)

5.1.3 Purpose of a compression tester

- To measure the pressure that the piston will create when moving from bottom dead centre to top dead centre (2)

5.2 Function of a cylinder leakage tester

- To check whether the engine leaks gases from the cylinder during compression stroke (2)

5.3 Set-up procedure of cylinder leakage test

- Turn the engine until both valves are closed on the cylinder under test

- Unscrew the spark plug and screw the adaptor into the spark plug hole

- Use the spanner to lock the crankshaft pulley

- Couple the compressed air pipe to the tester and then to the adaptor while the relief valve on the tester is closed

- Open the relief valve on the tester slowly

- Take the readings and compare with specification (6)

5.4 Reason for analysing exhaust gases

- To determine the amount of the different types of gases emitted from a car engine and compare with standards to ensure that it does not exceed the

safety limit. (2)

5.5

5.5.1 Bubble gauge

- It is used to test the caster, camber and king pin inclination angle of a motor vehicle (2)

5.5.2 Turntable

- A turntable makes it possible to turn the front wheel 20° in and zero the bubble gauge and then turn the wheel 20° out and check the caster reading (3)

5.5.3 Periscopic optical alignment gauge

- To check the toe-in and toe-out of a vehicle (1)

[23]

QUESTION 6: ENGINES (SPECIFIC)

6.1

6.1.1 Engine component

- Crankshaft (1)

6.1.2 Crankshaft parts labeling

- – Crank nose

- – Crankpin journals/Big end journal

- – Flywheel mounting

- – Main journals

- – Counterweights

- – Main journal oil way (6)

6.1.3 Function of the crankshaft

- To convert the reciprocating motion of the piston into a rotary motion (2)

6.1.4 Number of cylinders

- 4-cylinder (1)

6.2

6.2.1 Function of a vibration damper

- A vibration damper adds mass to the crankshaft on the opposite side of a normal flywheel in order to counteract the torsion of the crankshaft (2)

6.2.2 Parts labeling

- – Crankshaft

- – Crankshaft flange

- – Secondary flywheel

- – Friction disc

- – Friction spring

- – Spring plate (6)

6.3 Engine cylinder configuration

- In-line engines

- V-type engines

- Flat engines (Horizontally opposed engines) (Any 2 x 1) (2)

6.4 Factors that determine firing order

- Position of the crank on the crankshaft

- The arrangement of cams on the camshaft (2)

6.5.1 Lag

- It is a delay felt by the driver between pressing the accelerator pedal and feeling the turbo kick in (2)

6.5.2 Boost

- It is the increase in manifold pressure generated by the turbocharger in the intake manifold which exceeds the atmospheric pressure. (2)

6.5.3 Waste gate

- A component of a turbocharger that wastes some of the exhaust gases by causing it to bypass the turbocharger turbine. (2)

[28]

QUESTION 7: FORCES (SPECIFIC)

7.1 7.1.1 Clearance volume

- The volume of the space above the crown of the piston in the combustion chamber when the piston is at the top dead centre (2)

7.1.2 Compression ratio

- The relationship between the total volume of a cylinder when the piston is at bottom dead centre to the volume of the charge in the cylinder when the piston is at top dead centre. (2)

7.2 Cylinder bore

- Stroke = 85 mm = 8,5 cm

CV = 60 cm3

CR = 10 : 1

CR = ?? + ??

??

= 10 = ?? + 60

60

SV = 540 cm3

540 = ?2 × ?

4

540 = ? × ?2 × 8,5

4

D = 8,994 cm

= 90 mm (6)

7.3 Methods of increasing compression ratio

- Remove shims from between crankcase and cylinder block

- Fit thinner gasket between cylinder block and cylinder head

- Machine metal from cylinder head

- Skim metal from cylinder block

- Fit piston with suitable higher crowns

- Fit crankshaft with longer stroke

- Increase cylinder bore (Any 3 x 1) (3)

7.4 New compression ratio

- Bore increase by 4,8 mm

90 mm + 4,8 mm = 94,8 mm = 9,48 cm

SV = ? × 9,482 × 8,5

4

= 600 cm3

CR = 600+60

60

= 11 : 1 (5)

7.5

7.5.1 Indicated power

- P = PLANn

P = 1°100 kPa = 1 100 000 Pa

L = 80 mm = 0,08 m

D = 95 mm = 0,095 m

A = ? × 0,0952

4

= 7,088218425 × 10-3 m2

N = 4 200

60×2

= 35r/s

N = 4 cylinders

Indicated power= 1 100 000 x 0,08 x 7,088218425 x 10-3 x 35 × 4

= 87 326,85 W

= 87,33 kW (6)

7.5.2 Torque

- T = f×r

But f= mg = 35 x10

= 350 N

T = 350 x 0,5

= 175 Nm (3)

7.5.3 Brake power

- BP = 2 ? NT

= 2 x ? x 70 x 175

= 76 969,02 W

= 77 kW (3)

7.5.4 Mechanical efficiency

- Mechanical efficiency = ?? × 100%

??

= 77 × 100%

87.33

= 88,12% (2)

[32]

QUESTION 8: MAINTENANCE (SPECIFIC)

8.1

8.1.1 High hydrocarbon reading (possible causes)

- Incomplete combustion

- Improper timing

- Vacuum leak

- Faulty air management system (Any 1 x 1) (1)

8.1.2 Corrective measures

- Reset fuel mixture

- Check and reset ignition system

- Check and repair vacuum leaks (Any 1 x 1) (1)

8.1.3 High carbon monoxide (possible causes)

- Too rich mixture

- Ignition misfire

- Dirty air filter

- Bad fuel delivery system

- Faulty thermostat

- Bad PVC valve system

- Catalytic converter not working (Any 1 x 1) (1)

8.1.4 Corrective measures

- Reset fuel mixture

- Check misfire and repair

- Replace air filter

- Check and correct fuel delivery system

- Check and repair coolant sensor

- Check and replace the catalytic converter (Any 1 x 1) (1)

8.2 Compression test safety requirements

- Ensure the tester can handle the pressure you want to test

- Clean the plug hole environment with compressed air before removing the spark plug

- Ensure the relief valve is working

- Ensure the use of the correct adaptor for the plug hole

- Ensure the throttle valve is opened (Any 3 x 1) (3)

8.3 Manufactural specification (cylinder leakage test)

- Listen at intake for hissing sound (inlet valve leaking)

- Listen at exhaust for hissing sound (exhaust valve leaking)

- Listen for hissing sound in dip stick (piston rings worn)

- Listen for hissing sound after opening the tapper cover fillet cap (piston ring worn)

- If you see bubbles in the radiator water, the cylinder head gasket is blown

(Any 3 x 1) (3)

8.4 Low oil pressure reading (possible causes)

- Worn oil pump

- Blocked pick-up screen in the oil sump

- Worn main big-end and camshaft bearings

- Blocked oil filter

- Dirty or contaminated oil

- Oil leaks

- Too little oil in the engine

- Incorrect oil viscosity

- Defective oil pressure relief valve

(Any 3 x 1) (3)

8.5 Components for possible leakage

- Water hoses

- Blown cylinder head gasket

- Water pump

- Radiator

- Corroded core plugs

- Interior heater radiator

- Faulty radiator cap (Any 4 x 1) (4)

8.6 Manufactural specifications (cooling system pressure test)

- Ratio combination of antifreeze and water in the system

- Pressure allowed in the radiator

- Pressure of the radiator cap

- Reading of the water coolant tester

(Any 2 x 1) (2)

8.7

8.7.1 Fuel pressure too high (possible causes)

- Faulty fuel pump

- Blocked fuel filter

- Cracked or restricted fuel line

- Clogged fuel pump inlet strainer

- Low voltage to pump

- Faulty fuel pressure regulator

- Defective fuel pump relay

- Empty fuel tank

(Any 2 x 1) (2)

8.7.2 Fuel pressure too high (possible causes)

- Restriction in return fuel line

- Faulty fuel pressure regulator (2)

[23]

QUESTION 9: SYSTEMS AND CONTROL (AUTOMATIC GEARBOX) (SPECIFIC)

9.1 Purpose of automatic gearbox

- To relieve the driver of clutch and gearshift operation thereby allowing the driver to concentrate on driving the vehicle, promoting smoother and easier

driving (2)

9.2 Differences between an automatic gearbox and manual gearbox

- There is no clutch pedal in vehicles with automatic gearbox but there is a clutch pedal in vehicles with manual gearbox

- Gear shift happens automatically in automatic gearbox but it’s the driver’s responsibility to change gears in manual gearbox

- Automatic transmission uses thin oil while manual gearbox uses thicker oil

- Automatic transmission uses torque converter while manual gearbox uses clutch assemble (Any 2 x 1) (2)

9.3 Disadvantages of automatic gearbox

- It’s more expensive to manufacture

- The propeller shaft of an automatic transmission must be removed if the car is to be towed over a long distance

- If the starter fails, there are no other alternatives to get the engine running

(Any 2 x 1) (2)

9.4 Function of a torque converter

- To multiply engine torque automatically according to road and engine speeds (2)

9.5

9.5.1 Stall speed

- At stall speed, the maximum torque multiplication is delivered as the pump reaches the highest velocity but the turbine is still at rest.

That is when the vehicle is just about to start moving. (3)

9.5.2 Increasing speed

- The vehicle starts moving as the turbine begins to turn. As the speed increases, the torque multiplication tapers off gradually. (2)

9.6 Advantages of torque converter

- Torque increases automatically

- Torque is transferred smoothly

- Minimum servicing is required (Any 2 x 1) (2)

9.7 Advantages of transmission control unit (TCU)

- Better fuel economy

- Reduces engine emissions

- Greater shift system reliability

- Improved shift feel

- Improved shift speed

- Improved vehicle handling (Any 3 x 1) (3)

[18]

QUESTION 10: SYSTEMS AND CONTROL (AXLES AND STEERING GEOMETRY AND ELECTRONICS) (SPECIFIC)

10.1 Causes of camber wear

- Suspension misalignment

- Bent strut

- Dislocated strut tower

- Weak or broken spring

- Bent spindle

- Damaged control arm (Any 2 x 1) (2)

10.2 Different between positive and negative camber

- Positive camber is the outward tilt of the front wheel away from the vehicle when viewed from the front of the vehicle. While negative camber is the inward tilt of the front wheel into the vehicle when viewed from the front of the vehicle. (4)

10.3

10.3.1 Alignment angle

- Negative caster (2)

10.3.2 Parts labeling

- – Contact point of king pin Centre line

- – King pin

- – Perpendicular line

- – Negative caster angle

- – Centre line of king pin

- – Front of vehicle

- – Point of wheel contact (7)

10.3.3 Advantages of negative caster

- Easier turning of wheels

- Better corner qualities (2)

10.4 Factors to be considered before attempting wheel alignment adjustment

- Kerb mass

- Uneven wear on tyres

- Tyre pressure

- Run-out on the wheels

- Correct pre-load on the wheel bearing

- Kingpins and bushes

- Suspension ball joints for wears

- Suspension bushes for excessive free movement

- Steering box play

- Tie-rod ends

- Sagged springs

- Shock absorber

- Spring U-bolts

- Chassis for possible cracks and loose cross members (Any 2 x 1) (2)

10.5 Static balance

- It is the equal distribution of all weight around the axis of rotation in the rotation plane (2)

10.6 Pre-checks on wheels before balancing

- Check the tyres for bruises, cracks and damaged side walls

- Check the rim for any damage

- Check for any foreign object on the rim and tyre (Any 2 x 1) (2)

10.7

10.7.1 Alignment

- Ackermann principle (1)

10.7.2 Parts Labelling

- – Rear axle

- – Longitudinal axis

- – Steering arm

- – Front wheel

- – Extended centre lines from steering arms

- – Intersection (6)

10.7.3 Purpose

- To enable the correct turning angle of the front wheels when negotiating a curve in order to prevent skidding (2)

[32]

TOTAL: 200