Civil Technology: Construction Memorandum - Grade 12 September 2021 Preparatory Exams

Share via Whatsapp Join our WhatsApp Group Join our Telegram GroupINSTRUCTIONS FOR THE MARKERS

- Markers should:

- Familiarise themselves with the question and answer before evaluating the responses of candidates.

- Always interpret the responses of the candidates within the context of the question.

- Consider any relevant and acceptable answer during pre-marking but should strictly adhere to the answers after finalisation of the marking guideline.

- There are two approaches to answering questions, these are (1) to describe and (2) to explain.

- If a candidate is required to explain e.g., a process in 4 steps, only the first 4 responses should be considered.

- If, however a candidate is required to e.g., explain or describe how to transfer heights from one point to another using a transparent pipe level we need to consider that candidates may write a long description not necessarily well organised as an intellectual response may do. In this case the marker needs to evaluate the complete statement to judge if the candidate explained the required outcome satisfactorily and allocate marks on merit. The marker should apply his/her professional judgement with these types of questions.

- Mark what the candidate wrote and do not award marks for answers that the marker thinks the candidate meant with what was written.

- Indicate the tick or cross right at the position where the mark needs to be awarded or where the candidate made the error.

- Accept the letter corresponding with the correct answer as well as the answer written in full in multiple-choice questions.

- Accept incorrect spelling in one-word answers unless the spelling changes the meaning of the answer.

- For calculations:

- A mark is only awarded if the correct unit is written next to the answer.

- If TWO marks are awarded ONE mark is awarded for the answer and ONE mark for the correct unit.

- Where the candidate made a principle error e.g. added instead of multiplying, no marks will be awarded for the steps. If the answer is correct according to what the candidate did, the mark for the answer can be awarded for the application of skills.

- Where an incorrect answer could be carried over to the next step, the first answer will be deemed incorrect. However, should the incorrect answer be carried over correctly, the marker has to recalculate the values, using the incorrect answer from the first calculation. If correctly used, the candidate should receive the full marks for subsequent calculations.

- Markers should consider when and where a candidate has rounded off in a calculation, as well as the subsequent effect it has on the final answer obtained. The calculation should therefore be awarded marks on merit.

- Alternative methods of calculations must be considered, provided that the correct answer is obtained.

- When marking drawings:

- The member for which the mark should be awarded should be drawn correctly in the correct position to receive a mark.

- A member incorrectly drawn but wrongfully repeated in another position will be awarded the mark for the repeated incorrect member provided that the marking guideline provide for TWO or more marks for that member (positive marking).

- Marks can only be awarded for a label if the label is correctly indicating the correct member.

- Scale drawings should always be marked using an appropriate mask.

When a candidate drew the wrong drawing e.g.: - A horizontal section instead of a vertical section, no marks will be allocated to the drawing as the candidate did not respond to the expected outcome.

- An orthographic view instead of sectional view, no marks will be allocated to the drawing as the candidate did not respond to the expected outcome.

- An orthographic view instead of an isometric view, no marks will be allocated to the drawing as the candidate did not respond to the expected outcome.

- If the incorrect drawing was drawn, the candidate can be awarded for only what was asked but mark/s for the correctness of the drawing will not be awarded e.g., if a King Post roof truss was asked in the question, and candidate drew SA-Howe Truss.

MEMORANDUM

QUESTION 1: SAFETY AND MATERIALS (GENERIC)

1.1 Answer the following question regarding scaffolding.

1.1.1

- – Guardrail (1)

- – Planks / Working platform (1)

- – Kickboard / Toe-board (1)

- – Brace (1) (4)

1.1.2 228 mm (1) x 38 mm (1) (2)

1.1.3 Provides stability to scaffolding. (1)

1.1.4 Minimum = 900 mm (1) and maximum = 1 000 mm (1). (2)

1.2

1.2.1 Placing of building rubble:

- May not obstruct access or exits

- Safe place

- Regularly removed (Any 1 x 1) (1)

1.2.2 When materials are transported to higher surfaces:

- Workers must maintain a safe distance

- Overhead protection (1)

1.3 Any THREE:

- Non-skid devices on the bottom

- Hooks at the upper ends

- Lashed, secure or fastened

- Held by someone (Any 3 x 1) (3)

1.4 Rungs (1)

1.5 The coating of a metal by electrolysis (1) with a thin layer of another metal. (1) (2)

1.6 To improve a metal’s corrosion resistance. (1) (1)

1.7 Any TWO:

- Adds strength to the metal

- Galvanised metals are thicker

- Galvanised nails and screws prevents staining (Any 2 x 1) (2)

[20]

QUESTION 2: GRAPHICS, JOINING AND EQUIPMENT (GENERIC)

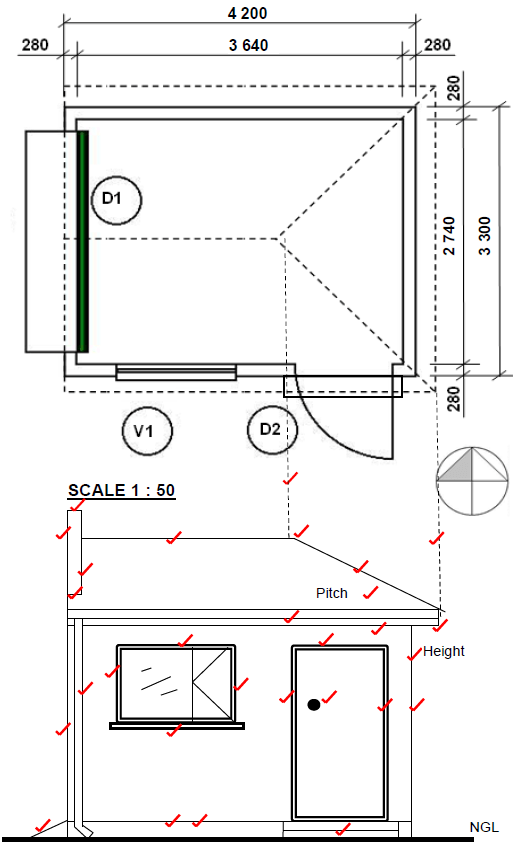

2.1 FIGURE 2.1 on ANSWER SHEET A shows a floorplan of a storeroom on scale 1 : 50. Draw the south elevation on scale 1 : 50 on ANSWER SHEET A from the given ground level, by using the following information:

- The floor level height is 200 mm above the ground level.

- Wall height is 2 600 mm from the floor level to the ceiling.

- Window 1 is 1 200 x 900 mm.

- Door 1 is 1 100 x 2 100 mm.

- Doorknob

- Roof construction pitch is 30°

- Show construction lines to determine the roof height.

- Gable end at the west elevation.

- Hippen end at the east elevation.

Use the marks table on ANSWER SHEET A as reference. (29)

2.2

- – Nut with built-in washer like a flange (1)

- – Wing nut (1)

- – Domed top nut (1) (3)

2.3 Any TWO:

- Resist pull-out failure

- Excellent carrying capacity

- Tolerance to a variance in the hole size (Any 2 x 1) (2)

2.4 Must be set-up that the telescope (1) is placed on a comfortable sightline (1) to prevent a person from bending or stretching over the telescope and tripod. (1)

(3)

2.5 Any THREE:

- Wiring

- Wood

- Metal studs

- Copper pipes

- Plumbing work (3 x 1) (3)

[40]

TOTAL SECTION A: 60

QUESTION 3: ROOFS, STAIRCASES AND JOINING (SPECIFIC)

3.1

3.1.1

- – Rafter (1)

- – Strut (1)

- – Tie beam (1)

- – King post (1)

- – Queen post (1)

3.1.2 South African / Howe roof (1)

3.1.3 114 mm (1) x 38 mm (1) (2)

3.2 Any TWO requirements that roof trusses should meet:

- Sturdy enough to carry the roof covering safely

- Able to withstand wind and other forces that act on them

- Provide adequate height in rooms below the roof and ceiling assembly

- Should not allow the accumulation of rainwater upon the roof surface

- Neat and solid to enhance the appearance of the buildings (Any 2 x 1) (2)

3.3

3.3.1 100 mm (1)

3.3.2 150 mm (1)

3.3.3 Reduce the fire hazard to neighbouring properties/structures. (1)

3.4 Any TWO advantages of the use of roof underlays:

- Acts as a secondary roof

- A weather shield during construction

- Waterproof and weatherproof

- Condensation barrier

- Dustproof

- Protects the building / structure

- Protects thermal insulation material

- Protects ceiling boards

- Superior wind uplifting strength prevents the lifting of tiles

- Vapour resistant

- High tensile resistance

- Cost effective

- High heat resistance (Any 2 x 1) (2)

3.5

3.5.1 2 100 mm (1)

3.5.2 100 mm (1)

3.5.3 750 mm (1)

3.6

3.6.1 Landing (1)

3.6.2 Riser (1)

3.6.3 Balustrade (1)

3.7

3.7.1

- – Baluster (1)

- – Handrail (1)

3.7.2 Any ONE material that can be used for a handrail:

- Stainless steel

- Timber

- Plastic

- Concrete

- Similar answer (1)

3.8

3.8.1 True (1)

3.8.2 False (1)

3.8.3 True (1)

3.8.4 False (1)

3.9 Any TWO types of cast-in anchors:

- Hex-head bolt with washer

- L-bolt

- J-bolt

- Welded headed stud (Any 2 x 1) (2)

[30]

QUESTION 4: MATERIAL, EQUIPMENT AND TOOLS, EXCAVATIONS (SPECIFIC)

4.1

4.1.1 H (alternative for glass) (1)

4.1.2 C (tested in a laboratory) (1)

4.1.3 D (non-ferrous metal) (1)

4.1.4 G (packaging material) (1)

4.1.5 F (tested on the site) (1)

4.1.6 A (ferrous metal) (1)

4.2

4.2.1 Slump test (1)

4.2.2 Any TWO reasons for the purposes of the slump test:

- To test the density of concrete (percentage water)

- To determine the workability and consistency of batches

- To determine the slump of the mixture (Any 2 x 1) (2)

4.2.3 Any ONE type of equipment that is used with the slump test:

- Metal base plate

- Cone

- Tamping rod

- Spirit level

- Ruler

- Measuring tape (Any 1 x 1) (1)

4.3 Any TWO purposes (reasons) for the curing of concrete:

- To help with the hydration of the cement

- Protect the concrete against quick drying

- To achieve optimal strength

- To achieve optimal hardness (Any 2 x 1) (2)

4.4 Any TWO purposes (reasons) for the cladding of buildings:

- Aesthetic purposes

- Functional purposes

- Help to control weather elements (rain / wind)

- Prevent runoff (water) from penetrating the building (Any 2 x 1) (2)

4.5 Any TWO types of cladding for buildings:

- Tile cladding

- Brick slip cladding

- Stone cladding

- Timber cladding

- Metal sheet cladding (Any 2 x 1) (2)

4.6

4.6.1 Portable concrete vibrator(1)

4.6.2 Any ONE purpose of the portable concrete vibrator:

- To distract air out of the concrete

- To get the concrete into the corners of the formwork

- To get the concrete around the reinforcing

- To compact the concrete

- Similar answer (Any 1 x 1) (1)

4.6.3 Any TWO ways of maintaining the concrete vibrator:

- Maintain – lubricate and adjust to manufacturer’s instruction

- Clean after use and store in a safe, dry place

- Repair / replace damaged electrical cords

- Service regularly (Any 2 x 1) (2)

4.7

4.7.1 True (1)

4.7.2 True (1)

4.7.3 True (1)

4.7.4 False (1)

4.8 Any THREE causes for the collapse of an excavation:

- Heavy rains

- Poor soil strata, structure or composition

- Sides not dug at the correct angle

- Improper use of formwork or shoring to support walls

- Vibration by machinery or heavy vehicles nearby

- Water seeping into the excavated area

- Contact with underground service

- Access to and exit from the excavation

- Soil slides due to cracks or loose soil (Any 3 x 1) (3)

4.9 Any TWO ways of making excavations safe during the night:

- Fencing

- Warning signs

- Warning lights (red or orange)

- Covering (Any 2 x 1) (2)

4.10

4.10.1 1,5 m (1)

4.10.2 1,3 m (1)

4.10.3 600 mm (1)

4.11

4.11.1 Pile foundation(1)

4.11.2 Stepped foundation (1)

4.11.3 Strip foundation (1)

4.11.4 Raft foundation (1)

4.12 Any FOUR advantages for the use of pile foundations:

- Can be used in poor soil

- Can be used anywhere, even in water

- Larger base ensure stability

- Relatively quick and easy installation – if equipment is available

- Much time can be saved if prefabricated piles are used

- Can be quick and less expensive to produce

- Resist tensile stress well

- Can be manufactured elsewhere and transported to site

- Installation can continue in poor weather

- Length of piles can be adjusted

- Offers good resistance against moving soil (Any 4 x 1) (4)

[40]

QUESTION 5: BRICKWORK, GRAPHICS, PLASTER AND SCREED (SPECIFIC)

5.1

5.1.1 Cavity wall (1)

5.1.2 Stretcher bond (1)

5.1.3 50 mm (1)

5.2 THREE disadvantages of cavity walls:

- Require expert design

- Require highly skilled workmanship

- Constant supervision is needed

- Cavities are fitted with vertical damp proof coursing

- More expensive

- 50 mm tot 100 mm of the internal space is lost (Any 3 x 1) (3)

5.3

5.3.1 Wall ties (1)

5.3.2 Minimum 150 mm above ground level (1)

5.3.3 To remove wasted mortar (1)

5.3.4 Water / Moisture can escape / Warm air dries walls out (1)

5.4 Any TWO types of wall ties:

- Butterfly pattern

- Nylon wall tie

- Twisted pattern

- Double triangular pattern (Any 2 x 1) (2)

5.5

5.5.1 C (prepared layer beneath paving and bedding sand) (1)

5.5.2 D (final layer upon which paving is laid) (1)

5.5.3 A (natural soil on which the paving will be laid) (1)

5.6 Name THREE advantages of dry-laid paving:

- Very economical / Cheap

- Low initial installation cost

- Designed to accommodate the lifting of individual pavers

- Can be easily repaired

- User-friendly installation materials

- Easy to repair underground utilities

- Can also be designed as a permeable pavement

- No off-gassing (harmful gasses) installation products are used (Any 3 x 1) (3)

5.7 Any TWO reasons for construction failure of paving:

- Concrete haunch is too thin to support itself and crumble under pressure

- Too little weight to retain the structure and keep paving in place

- Bond between the haunch and edge units is weak and crumble easily

- Sub-base is not contained and will be washed out by groundwater (Any 2 x 1) (2)

5.8 Draw a neat sketch with FOUR (4) bricks in the herringbone pattern in the ANSWER BOOK. (Use own appropriate scale.) (5)

(5)

5.9

5.9.1

- – Roof tiles / Concrete roof tiles / Tiles (1)

- – Rafter (1)

- – Damp proof course (DPC) (1)

- – Tie beam (1)

5.9.2 Any TWO advantages of a closed eave:

- Provides an attractive appearance

- Prevent birds, vermin and insects from nesting in the roof

- Beam filling is not compulsory (Any 2 x 1) (2)

5.10 Discuss the difference between the rough and gauged arches: Any TWO – Rough arch:

- Inexpensive / economical

- Standard plaster bricks

- Wedge-shape joints

- Normally plastered (Any 2 x 1) (2)

Any TWO – Gauged arch:

- Looks neat and aesthetic

- Wedge-shape special bricks

- Uniform normal joints

- Normally unplaster (Any 2 x 1) (2)

5.11 Sand (1) and cement (1) (2)

5.12 Any ONE purpose of builder’s lime:

- Enhance the workability of the mixture

- Enhance the plasticity of the mixture

- Reduce cracking and crazing of plaster (Any 1 x 1) (1)

5.13 Any TWO types of screed:

- Dry screed

- Monolithic screed

- Bonded screed (Any 2 x 1) (2)

[40]

QUESTION 6: FORMWORK, REINFORCING, CONCRETE FLOORS AND QUANTITIES (SPECIFIC)

6.1 Any TWO materials to obtain a smoother finish on concrete:

- Plastic

- Metal sheeting

- Hardboard

- Fibreglass

- Similar answer (Any 2 x 1) (2)

6.2 Any TWO types of timber boards for formwork:

- Block board

- Laminated board

- Shutter board

- Plywood (Any 2 x 1) (2)

6.3 Any THREE properties of good formwork:

- Made accurately according to the dimensions indicated

- Sturdy enough to bear the mass of wet concrete without collapsing

- Able to bear the mass of workers and equipment

- Must be strong enough to provide enough support, without too much deflection, until the concrete has set

- Must withstand the pressure of the compacting and the vibrating of the concrete

- Formwork should be easy to repair on site

- Secured with wire nails, where some should protrude for easy extracting

- Secured with bolts from 13 mm to 19 mm in diameter

- Should be sealed properly so that the concrete does not leak and form honeycombs or fins

- Should be free of dirt (sawdust or releasing agents)

- Quick and simple to erect, mechanically or by hand

- Ensure the correct cover depth for reinforcing, to prevent structural failure

- Fit plywood onto laggings if a smooth finish is required

- Remove when the concrete has cured and is able to the support load

- Should be easy to remove without damaging the formwork or concrete

- Close-fitting along seams and joints

- Made from recyclable components (Any 3 x 1) (3)

6.4

6.4.1

- – Hollow-core concrete blocks / Hollow concrete block / Block (1)

- – Pre-stressed concrete rib / Precast ribs / Rib (1)

6.4.2 Rib-and-block floor (1)

6.4.3 Any ONE disadvantage of the rib-and-block floor:

- Requires mechanical handling on the site

- Requires manual labour to place blocks between the ribs (Any 1 x 1) (1)

6.5

6.5.1 High tensile steel (High yield steel) (1)

6.5.2 10 Rods (1)

6.5.3 250 mm (1)

6.6

6.6.1 Shear force / Shearing (1)

6.6.2 Compression force / Compression stress (1)

6.7 Any THREE properties (requirements) for reinforced steel bars:

- Free of salt spray, mud, splinters and any oiliness

- Completely covered in concrete to protect it against rust and fire hazards

- Resistant to tensile stress

- Easy to bend into shape

- Able to bind firmly with concrete

- Of limited expansion prevent tension when the temperature fluctuates

- Readily available and affordable

- Must be rustproof, otherwise it will impair binding (Any 3 x 1) (3)

6.8 Any TWO purposes of the cover depth:

- To protect steel against corrosion

- To ensure adequate bonding between the steel and concrete

- To ensure adequate protection of steel in the event of a fire (Any 2 x 1) (2)

6.9 Foundation strips of a garage is 6 250 x 2 750 (inside measurements). The foundation is 600 mm wide and 200 mm thick.

6.9.1 Calculate the centreline of the foundation:

- 2 / 6 250 = 12 500

2 / 2 750 = 5 500

18 000

Plus corners: 4 / 600 = 2 400

20 400 of 20,4 m (5)

6.9.2 Calculate the volume of concrete needed.

- Volume = length x width x thickness

= 20,4 m x 0,6 m x 0,2 m

= 2,448 m³ of 2,45 m³ (4)

[30]

TOTAL: 200

ANSWER SHEET A

2.1 FIGURE 2.1 shows the floorplan of a storeroom on scale 1 : 50.

Draw the south elevation on scale 1 : 50 on ANSWER SHEET A from the given ground level. (29)

Floor level | 2 | |

Wall | 3 | |

Window | 3 | |

Window sill | 1 | |

Door | 4 | |

Stairs | 1 | |

Ramp | 1 | |

Fascial board | 2 | |

Gutter | 1 | |

Down pipe | 1 | |

Gable end | 4 | |

Hipped end | 3 | |

Roof height | 3 | |

TOTAL: | 29 |