MECHANICAL TECHNOLOGY(WELDING AND METALWORK) GRADE 12 QUESTIONS - NSC EXAMS PAST PAPERS AND MEMOS MAY/JUNE 2021

Share via Whatsapp Join our WhatsApp Group Join our Telegram GroupMECHANICAL TECHNOLOGY: WELDING AND METALWORK

GRADE 12

NATIONAL SENIOR CERTIFICATE EXAMINATION

MAY/JUNE2021

INSTRUCTIONS AND INFORMATION

- Write your centre number and examination number in the spaces provided on the ANSWER BOOK.

- Read ALL the questions carefully.

- Answer ALL the questions.

- Number the answers correctly according to the numbering system used in this question paper.

- Start EACH question on a NEW page.

- Show ALL calculations and units. Round off final answers to TWO decimal places.

- Candidates may use non-programmable scientific calculators and drawing instruments.

- The value of gravitational acceleration should be taken as 10 m/s2.

- All dimensions are in millimetres, unless stated otherwise in the question.

- Write neatly and legibly.

- A formula sheet is attached at the end of the question paper.

- Use the criteria below to assist you in managing your time.

| QUESTION | CONTENT | MARKS | TIME IN MINUTES |

| GENERIC | |||

| 1 | Multiple-choice Questions | 6 | 6 |

| 2 | Safety | 10 | 10 |

| 3 | Materials | 14 | 14 |

| SPECIFIC | |||

| 4 | Multiple-choice Questions | 14 | 10 |

| 5 | Terminology(Templates) | 23 | 20 |

| 6 | Tools and Equipment | 18 | 15 |

| 7 | Forces | 45 | 42 |

| 8 | Joining Methods(Inspection of Welds) | 23 | 20 |

| 9 | Joining Methods(Stresses and Distortion) | 18 | 15 |

| 10 | Maintenance | 8 | 8 |

| 11 | Systems and Control (Drive Systems) | 21 | 20 |

| TOTAL | 200 | 180 | |

QUESTION 1: MULTIPLE-CHOICE QUESTIONS (GENERIC)

Various options are provided as possible answers to the following questions. Choose the answer and write only the letter (A–D) next to the question numbers (1.1 to 1.6) in the ANSWER BOOK, e.g. 1.7 A.

1.1 Which Act promotes non-discrimination in the workplace?

- Employment Relations Act

- Employment Equity Act

- Employment Conditions Act

- Employment Health and Safety Act(1)

1.2 Which statement below is CORRECT in terms of the recommendations for the application of first aid? Do NOT …

- remove anything that is stuck to the wound.

- check the pulse of the patient.

- cool the patient's wound with cold water.

- pay attention to blood loss or breathing difficulties.(1)

1.3 Workshops with more than five workers must be equipped with a first-aid box. Which Act determines the content of the first-aid box?

- Employment Relations Act, 1998 (Act 56 of 1998)

- Employment Equity Act, 1998 (Act 55 of 1998)

- Occupational Health and Safety (OHS) Act, 1993 (Act 85 of 1993)

- Labour Relations Act, 1995 (Act 66 of 1995) (1)

1.4 Which test can be done to determine the ductility of a metal?

- Sound test

- Hardness test

- Bending test

- Machining test (1)

1.5 What is the purpose of case hardening during the heat-treatment process? To produce a …

- tough case over a hard core

- hard case over a thin core

- hard case over a hard core

- hard case over a tough core(1)

1.6 Which process causes severe scaling of a work piece during the heat treatment of ferrous metals?

- Normalising

- Annealing

- Tempering

- Hardening (1)

[6]

QUESTION 2: SAFETY (GENERIC)

2.1 First aid is a basic treatment to help an injured person and usually occurs in three stages. Name the THREE stages.(3)

2.2 State TWO safety precautions when using a drill press after it has already been switched on.(2)

2.3 Why must the electrode holder of an arc welding machine be isolated?(1)

2.4 State TWO disadvantages of the process workshop layout. (2)

2.5 State TWO advantages of the product workshop layout. (2)

[10]

QUESTION 3: MATERIALS (GENERIC)

3.1 All heat-treatment processes involve the heating and cooling of metals according to a time-temperature cycle. Describe this cycle.(3)

3.2 Name any THREE types of quenching mediums used during the heat-treatment processes.(3)

3.3 Give ONE reason why steel is annealed.(1)

3.4 Carbon steel is classified into three groups. Name the THREE groups.(3)

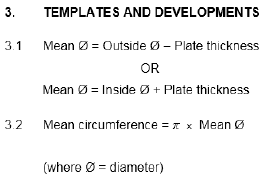

3.5 In FIGURE 3.5 below the iron-carbon equilibrium diagram is shown. Label the diagram as indicated, from A to D. Write down only the answer next to the letter (A–D) in the ANSWER BOOK. (4)

(4)

[14]

QUESTION 4: MULTIPLE-CHOICE QUESTIONS (SPECIFIC)

Various options are provided as possible answers to the following questions. Choose the answer and write only the letter (A–D) next to the question numbers (4.1 to 4.14) in the ANSWER BOOK, e.g. 4.15 E.

4.1 A plate girder is defined as a combination of …

- a roof truss and a foundation.

- a roof truss and a gusset plate.

- plates welded together.

- plates and angle iron welded together. (1)

4.2 What does the abbreviation TSU stand for?

- Template straight up

- Top side up

- Truss steel users

- Tapered side up (1)

4.3 What does the supplementary symbol indicate in FIGURE 4.3?

- Convex

- Concave

- Chisel

- Site weld (1)

4.4 The use of a die during thread cutting is to …

- cut internal thread.

- cut external thread.

- adjust the feed of a tap.

- adjust a stock. (1)

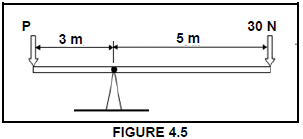

4.5 What is the magnitude of force P in FIGURE 4.5 to keep the system in equilibrium?

- 60 N

- 40 N

- 90 N

- 50 N (1)

4.6 What is the measure unit for stress?

- Metre (m)

- Pascal (Pa)

- Newton (N)

- No unit (1)

4.7 Which ONE of the following steps can be taken to reduce spatter during the welding process?

- Preheating of the base metal

- Slow cooling after welding

- Using the lower strength consumables

- By selecting the appropriate current setting (1)

4.8 Which ONE of the following tests is an example of a destructive test on a welded joint?

- Ultrasonic test

- X-ray test

- Nick-break test

- Sound test (1)

4.9 A safe gap between the tool rest and the grinding wheel of a bench grinding machine is …

- 2 mm.

- 3 mm.

- 4 mm.

- 5 mm. (1)

4.10 Which ONE of the following factors affect the grain size of the steel when being cold worked?

- Continuous welding

- The melting point of steel

- The temperature and time of the annealing process

- The cooling rate of the steel (1)

4.11 Which ONE of the following is a reason for lock-out and tagging during maintenance of machines? To inform other workers that …

- maintenance work is being done

- an accident has happened

- maintenance work has been completed

- a power failure occurred (1)

4.12 Which ONE of the following factors should be considered when selecting the cutting speed of a drill bit?

- Overloading

- Size of drill bit

- Spindle size

- Cutting angle (1)

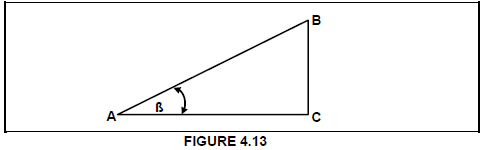

4.13 Which formula will one use to calculate cosβ?

- cosβ = AC

AB - cosβ = BC

AB - cosβ = AB

AC - cosβ = AB

BC (1)

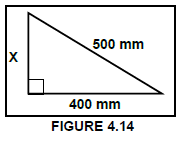

4.14 What is the value of X in FIGURE 4.14?

- 700 mm

- 600 mm

- 300 mm

- 200 mm (1)

[14]

QUESTION 5: TERMINOLOGY (TEMPLATES) (SPECIFIC)

5.1 Why does the template loft floor have permanent base and centre lines? (1)

5.2 Describe the purpose of purlins as used on roof trusses. (2)

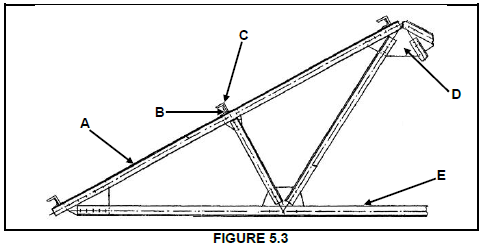

5.3 FIGURE 5.3 shows a roof truss.

Label parts A–E. (5)

5.4 A mild steel ring must be manufactured, using a 16 x 16 mm square mild steel bar. The inside diameter of the ring is 230 mm. Calculate the dimensions of the material needed to fabricate the ring. (6)

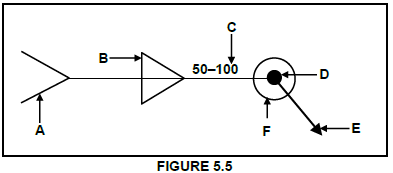

5.5 Identify elements A–F on the welding symbol shown in FIGURE 5.5. (6)

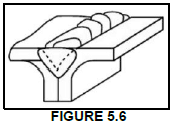

5.6 Sketch the weld symbol for the welded joint in FIGURE 5.6. (3)

[23]

QUESTION 6: TOOLS AND EQUIPMENT (SPECIFIC)

6.1 Describe the working principles of a plasma cutter. (4)

6.2 State TWO uses of a hydraulic press. (2)

6.3 Describe the internal thread-cutting process by using a thread-cutting tap. (3)

6.4 Describe the function of a power saw. (1)

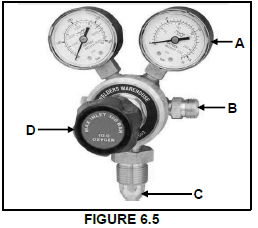

6.5 FIGURE 6.5 shows a component of gas welding equipment. Answer the questions that follow.

6.5.1 Identify the component shown in FIGURE 6.5. (1)

6.5.2 Label parts A–D. (4)

6.6 What is the colour code of an acetylene gas cylinder? (1)

6.7 What is the purpose of the flashback arresters on gas welding equipment? (2)

[18]

QUESTION 7: FORCES (SPECIFIC)

7.1 Define the following terms:

7.1.1 Stress (2)

7.1.2 Hooke's law (2)

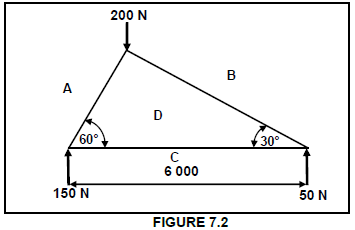

7.2 FIGURE 7.2 is a diagram of a steel frame structure. Answer the questions that follow.

7.2.1 Construct the space diagram according to the given scale of 10 mm = 1 m. (4)

7.2.2 Construct the vector diagram using scale 1 mm = 1 N. (5)

7.2.3 Determine the magnitude and the nature of the forces in members AD, BD and CD from the vector diagram. (6)

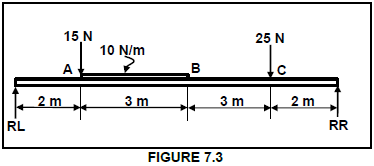

7.3 FIGURE 7.3 shows a beam of 10 metres long, supported by two vertical supports, RL and RR. Two vertical point loads, 15 N and 25 N, are exerted onto the beam. A uniformly distributed load of 10 N/m is exerted over a length of 3 m. Answer the questions that follow.

7.3.1 Calculate the magnitude of the reactions in supports RL and RR. (6)

7.3.2 Calculate the shear force at points A, B and C. (6)

7.3.3 Use the scale below to draw the shear force diagram.

Scale: Space diagram: 10 mm = 1 m

Shear force diagram: 1 N = 1 mm (6)

7.4 A tensile force of 80 kN is exerted onto a round bar with a diameter of 30 mm. The original length of the round bar is 3 m.

7.4.1 Calculate the stress caused in the material in MPa.(6)

7.4.2 Calculate the strain caused if the change in length of the bar is 0,06 mm. (2)

[45]

QUESTION 8: JOINING METHODS (INSPECTION OF WELDS) (SPECIFIC)

8.1 State TWO causes of EACH of the following arc-welding defects:

8.1.1 Slag inclusion (2)

8.1.2 Incomplete penetration (2)

8.2 State TWO preventative measures for the following welding defects during arc welding:

8.2.1 Porosity (2)

8.2.2 Lack of fusion (2)

8.3 Give ONE reason for performing the following tests on a welded joint:

8.3.1 Free-bend test (1)

8.3.2 X-ray test (1)

8.4 Name THREE types of welding cracks. (3)

8.5 State TWO factors that should be observed during the oxy-acetylene welding process. (2)

8.6 Describe the steps to be followed when performing a nick-break test on a welded joint. (5)

8.7 Explain why non-destructive tests are preferred to destructive tests. (1)

8.8 Give TWO reasons for performing a machinability test on a welded joint. (2)

[23]

QUESTION 9: JOINING METHODS (STRESSES AND DISTORTION) (SPECIFIC)

9.1 State FOUR factors that affect the temperature at which cold-worked steel will recrystallise when heated. (4)

9.2 What effect would the following have on shrinkage in a welded joint?

9.2.1 Electrode type (1)

9.2.2 Size of electrode (1)

9.2.3 Welding current (1)

9.3 State TWO factors that determines the cooling rate of welded metals. (2)

9.4 Define the following welding terms:

9.4.1 Distortion (2)

9.4.2 Shrinkage (2)

9.5 State THREE factors affecting distortion and residual stress in a welded joint. (3)

9.6 State TWO causes of residual stress in a welded joint. (2)

[18]

QUESTION 10: MAINTENANCE (SPECIFIC)

10.1 What would be the effect of overloading on the following equipment?

10.1.1 Shearing machine (1)

10.1.2 Drill press (1)

10.2 What would be the negative effect of friction on the following equipment?

10.2.1 Guillotine (1)

10.2.2 Horizontal band saw (1)

10.3 State TWO general maintenance guidelines for a power saw with reference to electrical switches and the condition of the wiring. (2)

10.4 State TWO methods used to reduce friction when drilling holes. (2)

[8]

QUESTION 11: TERMINOLOGY (DEVELOPMENT) (SPECIFIC)

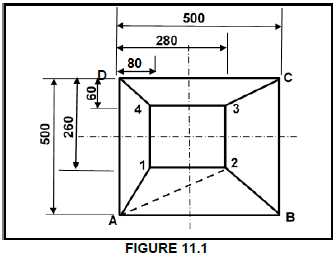

11.1 FIGURE 11.1 shows a square-to-square off-centre hopper with a vertical height of 400 mm. Answer the questions that follow.

Calculate the true lengths of the following sides:

11.1.1 A–2 (5)

11.1.2 C–3 (5)

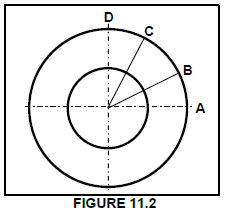

11.2 FIGURE 11.2 shows a truncated cone. The vertical height of the truncated cone is 600 mm, and the base and top diameters are 600 mm and 400 mm respectively. Answer the questions that follow.

11.2.1 Calculate the true length of A–B. (5)

11.2.2 Calculate the circumference of the top circle. (4)

11.2.3 What is the value of the true vertical height of the truncated cone? (2)

[21]

TOTAL: 200

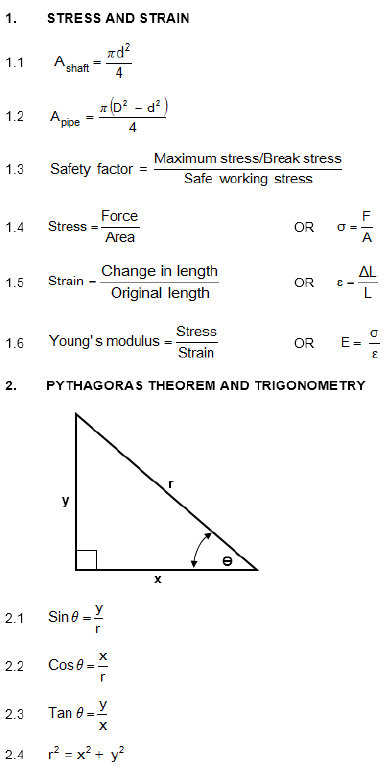

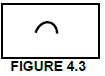

FORMULA SHEET FOR MECHANICAL TECHNOLOGY: WELDING AND METALWORK