Mechanical Technology: Automotive Grade 12 Questions - NSC Past Papers And Memos September 2020 Preparatory Examinations

Share via Whatsapp Join our WhatsApp Group Join our Telegram GroupINSTRUCTIONS AND INFORMATION

- Write your full names on the ANSWER BOOK.

- Answer ALL the questions.

- Number the answers correctly according to the numbering system used in this question paper.

- Start EACH question on a NEW page.

- Show ALL calculations and units. Round off final answers to TWO decimal places.

- Candidates may use non-programmable scientific calculators and drawing instruments.

- The value of gravitational acceleration should be taken as 10 m.s-2

- All dimensions are in millimeters, unless stated otherwise in the question.

- A formula sheet is attached to the question paper.

- Write neatly and legibly.

- Use the criteria below to assist you in managing your time.

QUESTION | CONTENT | MARKS | TIME in minutes |

GENERIC | |||

1 | Multiple-choice questions | 6 | 6 |

2 | Safety | 10 | 10 |

3 | Materials | 14 | 14 |

SPECIFIC | |||

4 | Multiple-choice questions | 14 | 10 |

5 | Tools and Equipment | 23 | 20 |

6 | Engines | 28 | 25 |

7 | Forces | 32 | 25 |

8 | Maintenance | 23 | 20 |

9 | Systems and Control (Automatic Gearbox) | 18 | 20 |

10 | Systems and Control (Axles, Steering Geometry and Electronics) | 32 | 30 |

TOTAL | 200 | 180 | |

QUESTIONS

QUESTION 1: MULTIPLE-CHOICE QUESTIONS (GENERIC)

Various options are provided as possible answers to the following questions. Choose the correct answer and write only the letter (A–D) next to the question numbers (1.1–1.6) in the ANSWER BOOK, for example 1.7 D.

1.1 Which of the following safety measures is applicable to guillotines in terms of the Occupational Health and Safety Act?

- Clamp the workpiece securely to the table.

- Do not leave the chuck key on the machine.

- Machine must be fitted with fixed guards to prevent fingers from reaching through the point of operation.

- Use the table of the machine as an anvil. (1)

1.2 What is the purpose of cooling the blade of a band saw with cutting fluid?

- To cause friction

- To ensure clean cuts and remove metal waste

- To ensure straight cuts

- To move the blade forward and backwards (1)

1.3 Which ONE of the following safety procedures is applicable to the operation of a hydraulic press?

- Do not apply wrench to revolving work.

- Guards could be removed when pressing soft material.

- Pressure gauges must be tested regularly and adjusted or replaced if any malfunction occurs.

- Use the machine table as an anvil. (1)

1.4 Which ONE of the following tests is used to measure the ductility of a metal?

- Bend tests

- Sound tests

- Hardness tests

- Machining tests (1)

1.5 File tests are used as the simplest method of checking the ... of material.

- toughness

- hardness

- ductility

- softness (1)

1.6 Sound tests can be performed by tapping a material with a …

- hacksaw.

- spanner.

- hammer.

- file. (1)

[6]

QUESTION 2: SAFETY (GENERIC)

2.1 Name any TWO pieces of personal safety equipment that you need to wear when using gas welding equipment.(2)

2.2 Give TWO safety rules that must be followed while the surface grinder is in operation. (2)

(2)

2.3 When completing a task on any machine, what safety aspect must be considered before leaving the machine? (1)

2.4 State TWO safety measures to observe before switching the angle grinder on. (2)

(2)

2.5 Why is it important to wear a welding helmet when using arc welding equipment? (1)

2.6 Name TWO types of workshop layouts. (2)

[10]

QUESTION 3: MATERIALS (GENERIC)

3.1 The following table shows the different types of tests and materials.

Copy and complete the table in your ANSWER BOOK by stating how these materials will react under the different tests.

| MATERIALS | DIFFERENT TYPES OF TESTS | ||

| Sound | Filing | Bend | |

| Cast iron | |||

| Mild steel | |||

(6)

3.2 Explain the purpose of heat-treatment processes. (1)

3.3 The hardness that can be achieved from a specific treatment depends upon THREE factors. Name any TWO factors. (2)

3.4 Explain the purpose of the following heat treatment processes:

3.4.1 Tempering (2)

3.4.2 Annealing (2)

3.5 What does the hardness of steel depend upon? (1)

[14]

QUESTION 4: MULTIPLE-CHOICE QUESTIONS (SPECIFIC)

Various options are provided as possible answers to the following questions. Choose the answer and write only the letter (A–D) next to the question numbers (4.1–4.14) in the ANSWER BOOK, for example 4.15 A.

4.1 FIGURE 4.1 shown below is an OBDII car diagnosis machine.

FIGURE 4.1

Which ONE of the following applications does NOT require the use of this tool?

- Determine the castor angle of a wheel

- Scan a car electronic control module (ECM)

- Detect faults in the form of codes

- Clear errors decoded by a car electronic control module (1)

4.2 During the process of applying the emission gas analyser on a car’s exhaust system, which ONE of the following set-up procedures is NOT applicable?

- Connect the analyser to the 12-volt vehicle battery terminals

- Do not connect the armoured hose from the condenser pick-up to the rear of the machine until the display is 0.00

- Release the pressure built up in the system with the pressure release valve

- Insert the silicon hose probe and clamp unto the exhaust tail pipe (1)

4.3 Which ONE of the following types of equipment is used to determine the percentage leakage of a cylinder in an internal combustion engine?

- Bubble gauge

- Emission gas analyser

- Compression tester

- Cylinder leakage tester (1)

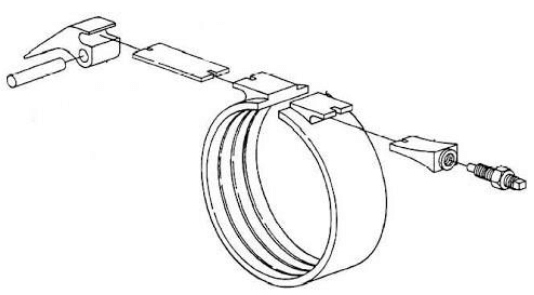

4.4 Identify the equipment shown in FIGURE 4.4 below.

FIGURE 4.4

- Pump

- Brake band

- Stator

- Impeller (1)

4.5 What is the name of the total volume displaced when a piston moves from bottom dead centre to top dead centre in an internal combustion?

- Clearance volume

- Swept volume

- Compression volume

- Cylinder volume (1)

4.6 What is the purpose of the waste gate of a turbocharger of an internal combustion engine?

- Provides more boost to the engine

- Cool the air coming to the inlet manifold

- Waste excess oxygen coming to the combustion chamber

- Waste some exhaust gases by causing it to bypass the turbocharger turbine (1)

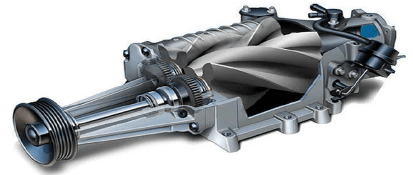

4.7 FIGURE 4.7 shown below is a supercharger.

FIGURE 4.7

Identify the type of supercharger:

- Roots supercharger

- Centrifugal supercharger

- Twin-screw supercharger

- Sliding-vane supercharger (1)

4.8 What is the purpose of a catalytic converter in the exhaust system of a spark ignition (SI) engine vehicle?

- Regulates the amount of oxygen in the exhaust manifold

- Permits the flow of exhaust gases in one direction only

- Prevents flow of exhaust gases

- Converts the pollutants in the exhaust gases of the engine into a non-toxic substance (1)

4.9 Lambda oxygen sensors are installed in the exhaust outlet of the turbine of turbo chargers to sense the oxygen content of the exhaust gases. Why are they installed in turbocharged cars?

- Turbocharged cars have a high carbon exhaust content

- Turbocharged cars have a high air boost in the inlet manifold

- Turbocharged cars have a high fuel consumption

- There is no air flow metre (1)

4.10 How does the idle speed control valve influence the speed of an engine at cold start?

- Increases the speed of an engine at cold start

- Decreases the speed of an engine at cold start

- Prevents the engine from overheating by regulating the idle speed at cold start

- Causes the engine to stop running as the temperature rises (1)

4.11 Which ONE of the following is the correct function of the throttle position sensor in an air induction system?

- Controls the oxygen content in the exhaust gases

- Adjusts the throttle valve for maximum performance

- Detects the position of the throttle valve

- Detects the position of the camshaft (1)

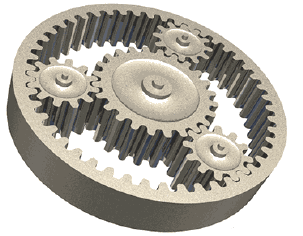

4.12 Identify the type of gear system arrangement displayed in FIGURE 4.12 below.

FIGURE 4.12

- Double gear arrangement

- Single gear arrangement

- Double epicyclic gear system

- Single epicyclic gear system (1)

4.13 Which ONE of the following is a possible cause of an engine over-heat?

- Faulty alternator

- Faulty water pump

- Too much oil in the sump

- Leakage in the fuel line (1)

4.14 How does camber affect tyre wears?

- One side of the tyre wears excessively

- Thin outer or inner edge wear

- Uniform tyre wear

- Prevents tyre wear (1)

[14]

QUESTION 5: TOOLS AND EQUIPMENT (SPECIFIC)

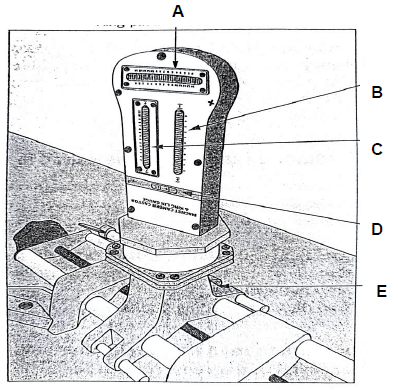

5.1 The figure below shows the alignment equipment used in an automotive workshop. Answer the questions that follow.

FIGURE 5.1

5.1.1 Identify the equipment in FIGURE 5.1. (1)

5.1.2 Label parts A–E. (5)

5.1.3 List THREE alignment angles that can be tested with the tool in FIGURE 5.1 above. (3)

5.2 In point form, describe the set-up procedures you must follow when reading the camber in the alignment settings of a car suspension system using a

bubble gauge. (5)

5.3 Name THREE faults that can be established when performing dynamic wheel balancing. (3)

5.4 What is the main purpose of the following tools in an automotive workshop?

5.4.1 Turn table (2)

5.4.2 Wheel balancer (2)

5.4.3 Optical alignment tool (2)

[23]

QUESTION 6: ENGINES (SPECIFIC)

6.1 A crankshaft is subject to vibrations as the engine runs. Give TWO factors responsible for this vibration. (2)

6.2 List TWO types of vibration damper used in an engine. (2)

6.3 How does the following built-in feature improve engine balance?

6.3.1 Crankshaft (2)

6.3.2 Connecting rods and pistons (2)

6.3.3 Flywheels (2)

6.4 State THREE factors that determine the configuration of an engine. (3)

6.5 List any TWO types of engine cylinder configurations. (2)

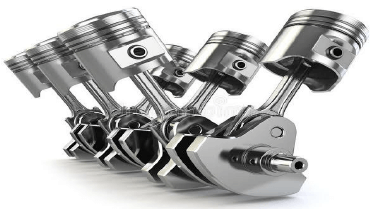

6.6 What type of engine configuration is displayed in FIGURE 6.6 below?

FIGURE 6.6 (1)

6.7 Give TWO factors that determine the firing order of an engine. (2)

6.8 What is the firing order of a five cylinder in-line engine? (1)

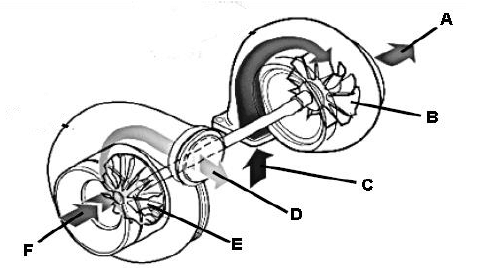

6.9 The figure below shows the internal components of a turbo charger. Label parts A–F. (6)

FIGURE 6.9

6.10 List any THREE disadvantages of using a turbocharger in an internal combustion engine. (3)

[28]

QUESTION 7: FORCES (SPECIFIC)

7.1 What do you understand by the term compression ratio? (2)

7.2 A compression ignition engine (CI) has a cylinder diameter of 90 mm, a stroke length of 110 mm and a clearance volume of 70 cm3.Calculate the compression ratio of the engine. (6)

7.3 What will be the new compression ratio of the engine IF the engine in QUESTION 7.2 undergoes overhauling and in the process the bore is increased to 96,1 mm in order to fit into a bigger, new piston? (4)

7.4 Give any FOUR methods that can be used to raise the compression ratio of an internal combustion engine. (4)

7.5 What do you understand by the term indicated power of an engine? (2)

7.6 The following data was recorded during a test carried out on a four-stroke, four-cylinder petrol engine:

- Mean effective pressure on the piston: 1 200 kPa

- Length of stroke: 86 mm

- Cylinder bore: 90 mm

- Revolutions per minute: 4 200 rpm

- Torque: 180 Nm @ 4200 rpm

- Number of cylinders: 4

Calculate the following:

7.6.1. Indicated power in kW (7)

7.6.2. The brake power in kW (3)

7.6.3. Mechanical efficiency (2)

7.7 What do you understand by the term mechanical efficiency of an internal combustion engine? (2)

[32]

QUESTION 8: MAINTENANCE (SPECIFIC)

8.1 A car exhaust gas was analysed and it was discovered that there was a high carbon monoxide reading.

8.1.1 State THREE possible causes that may be responsible for the high carbon monoxide reading. (3)

8.1.2 Give THREE necessary measures that can be taken to correct the faults. (3)

8.1.3 Name THREE other gases that may be analysed during the process of exhaust gas analysis. (3)

8.2 During the process of compression testing on a 6-cylinder SI engine, it was discovered that two of the cylinders had an unusually low reading. What will

be the next step to verify the condition of these two cylinders? (1)

8.3 During a cylinder leakage testing procedure, it was discovered that there are some signs of failure in the cylinders. What are the possible causes of the following failures?

8.3.1 Hissing sound from the inlet manifold (1)

8.3.2 Bubbles from radiator (1)

8.3.3 Hissing sound from the dip stick (1)

8.4 Give FOUR manufactural specifications that must be taken into account when conducting oil pressure testing. (4)

8.5 List THREE possible causes of low fuel pressure readings during fuel pressure testing. (3)

8.6 List any THREE possible components where the coolant could leak during cooling system pressure testing. (3)

[23]

QUESTION 9: SYSTEMS AND CONTROL (AUTOMATIC GEARBOX) (SPECIFIC)

9.1 What was the main purpose behind the design of an automatic gearbox in place of a manually driven gearbox? (2)

9.2 Give THREE advantages of using an automatic gear box. (3)

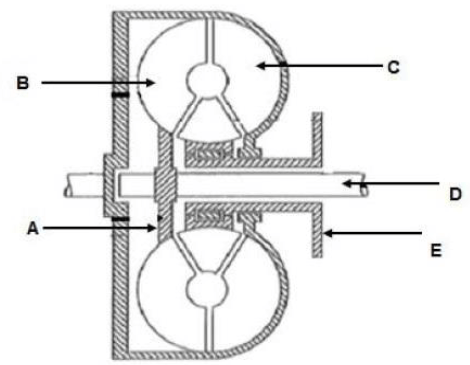

9.3 The diagram in FIGURE 9.3 below shows one of the components of an automatic transmission system.

FIGURE 9.3

Use the diagram to answer the following questions.

9.3.1 Identify the equipment in FIGURE 9.3 above. (1)

9.3.2 Label parts A–E in FIGURE 9.3 above. (5)

9.3.3 State THREE functions of the equipment in FIGURE 9.3 above. (3)

9.3.4 What is the function of the part labelled C? (2)

9.4 When the speed in a torque converter increases, how will it influence the torque multiplication? (2)

[18]

QUESTION 10: SYSTEMS AND CONTROL (AXLES, STEERING GEOMETRY AND ELECTRONICS) (SPECIFIC)

10.1 State FOUR properties of a good steering mechanism. (4)

10.2 With the aid of a neat and well labelled sketch, demonstrate the toe-in of the front wheel of a motor vehicle. (4)

10.3 State the purpose of each of the following angles:

10.3.1 Caster (2)

10.3.2 Ackermann principle (2)

10.3.3 King pin inclination (2)

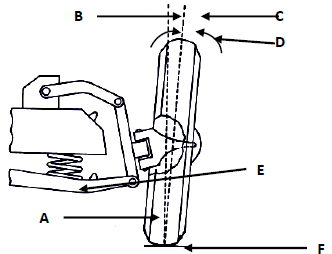

10.4 The diagram in FIGURE 10.4 below shows an alignment angle of a car front wheel. Answer the questions that follow.

FIGURE 10.4

10.4.1 Identify the type of alignment angle in FIGURE 10.4 above. (1)

10.4.2 Label the parts A–F in FIGURE 10.4 above. (6)

10.4.3 Briefly explain the type of alignment angle displayed in FIGURE 10.4 above. (2)

10.5 List FIVE factors that must be taken into account before wheel alignment can be checked or adjusted. (5)

10.6 What is the purpose of wheel balancing? (2)

10.7 Name the TWO types of wheel balancing used in tyre fitment centers. (2)

[32]

TOTAL: 200

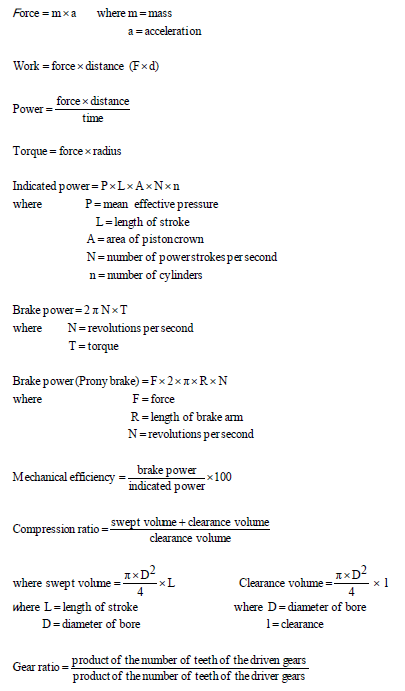

FORMULA SHEET FOR MECHANICAL TECHNOLOGY (AUTOMOTIVE)