Mechanical Technology: Fitting and Machining Grade 12 Questions - NSC Past Papers And Memos September 2020 Preparatory Examinations

Share via Whatsapp Join our WhatsApp Group Join our Telegram GroupINSTRUCTIONS AND INFORMATION

- Write your NAME on the ANSWER BOOK.

- Read ALL the questions carefully.

- Answer ALL the questions.

- Number the answers correctly according to the numbering system used in this question paper.

- Start EACH question on a NEW page.

- Show ALL calculations and units. Round off final answers to TWO decimal places.

- You may use a non-programmable scientific calculator and drawing instruments.

- The value of gravitational force should be taken as 10 m.s-2.

- All dimensions are in millimetres, unless stated otherwise in the question.

- A formula sheet is attached to the question paper.

- Write neatly and legibly.

- Use the criteria below to assist you in managing your time management.

QUESTION | CONTENT | MARKS | TIME In minutes |

GENERIC | |||

1 | Multiple-choice questions | 6 | 6 |

2 | Safety | 10 | 10 |

3 | Materials | 14 | 14 |

SPECIFIC | |||

4 | Multiple-choice questions | 14 | 10 |

5 | Terminology (Lathe and Milling) | 18 | 20 |

6 | Terminology (Indexing) | 28 | 25 |

7 | Tools and Equipment | 13 | 10 |

8 | Forces | 33 | 33 |

9 | Maintenance | 18 | 12 |

10 | Joining Methods | 18 | 12 |

11 | Systems and Control | 28 | 28 |

TOTAL | 200 | 180 | |

QUESTIONS

SECTION A: GENERIC

QUESTION 1: MULTIPLE-CHOICE (GENERIC)

Various options are provided as possible answers to the following questions. Choose the correct answer and write only the letter (A–D) next to the question numbers (1.1–1.6) in the ANSWER BOOK, for example 1.7 D.

1.1 Which of the following safety measures is applicable to guillotines in terms of the Occupational Health and Safety Act?

- Clamp the work piece securely to the table.

- Do not leave the chuck key on the machine .

- Machine must be fitted with fixed guards to prevent fingers from reaching through the point of operation.

- Use the table of the machine as an anvil. (1)

1.2 What is the purpose of cooling the blade of a band saw with cutting fluid?

- To cause friction

- To ensure clean cuts and remove metal waste

- To ensure straight cuts

- To move the blade forward and backwards (1)

1.3 Which ONE of the following safety procedures is applicable to the operation of a hydraulic press?

- Do not apply wrench to revolving work.

- Guards could be removed when pressing soft material.

- Pressure gauges must be tested regularly and adjusted or replaced if any malfunction occurs.

- Use the machine table as an anvil. (1)

1.4 Which ONE of the following tests is used to measure the ductility of a metal?

- Bend tests

- Sound tests

- Hardness tests

- Machining tests (1)

1.5 File tests are used as the simplest method of checking the ... of material.

- toughness

- hardness

- ductility

- softness (1)

1.6 Sound tests can be performed by tapping a material with a …

- hacksaw.

- spanner.

- hammer.

- file. (1) [6]

QUESTION 2: SAFETY (GENERIC)

2.1 Name any TWO pieces of personal safety equipment that you need to wear when using gas welding equipment. (2)

2.2 Give TWO safety rules that must be followed while the surface grinder is in operation. (2)

2.3 When completing a task on any machine, what safety aspect must be considered before leaving the machine? (1)

2.4 State TWO safety measures to observe before switching the angle grinder on. (2)

(2)

2.5 Why is it important to wear a welding helmet when using arc welding equipment? (1)

2.6 Name TWO types of workshop layouts. (2)

[10]

QUESTION 3: MATERIALS (GENERIC)

3.1 The following table shows the different types of tests and materials.

Copy and complete the table in your ANSWER BOOK by stating how these materials will react under the different tests.

| MATERIALS | DIFFERENT TYPES OF TESTS | ||

| Cast iron | Sound | Filing | Bend |

| Mild steel | |||

(6)

3.2 Explain the purpose of heat treatment processes. (1)

3.3 The hardness that can be achieved from a specific treatment depends upon THREE factors. Name any TWO factors. (2)

3.4 Explain the purpose of the following heat treatment processes:

3.4.1 Tempering (2)

3.4.2 Annealing (2)

3.5 What does the hardness of steel depend upon? (1)

[14]

QUESTION 4: MULTIPLE CHOICE (SPECIFIC)

Various options are provided as possible answers to the following questions. Choose the answer and write only the letter (A–D) next to the question numbers (4.1–4.14) in the ANSWER BOOK, for example 4.15 D.

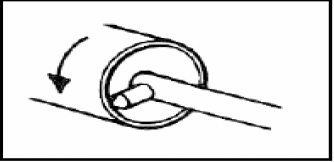

4.1 Which lathe operation is shown in FIGURE 4.1?

FIGURE 4.1

- Straight turning

- Internal parallel boring

- Thread cutting

- Reaming (1)

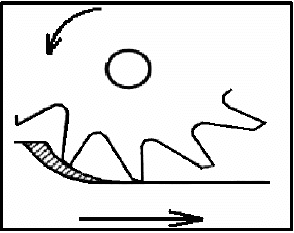

4.2 Identify the type of milling operation shown in FIGURE 4.2.

FIGURE 4.2

- Plain straight-tooth cutter

- Straight-tooth side-milling cutter

- Slitting saw

- Down-cut milling (1)

4.3 What is the purpose of cutting fluid?

- Acts as a non-lubricant

- Makes chips stick to the cutter

- Reduces the quality of the finish

- Cools a cutting tool and workpiece (1)

4.4 Compressive stress is stress that acts …

- against the length of an object.

- perpendicular to the surface.

- parallel to a surface.

- against the shortening of an object. (1)

4.5 What will the induced stress be, if a load of 50 N is applied to a square bar with a cross-sectional area of 144 × 10‾⁶ m² ?

- 347,22 kPa

- 3,47 kPa

- 0,347 kPa

- 34,7 kPA (1)

4.6 The main reason for performing a hardness test on engineering materials is to determine the …

- elasticity of the material.

- resistance of the material against denting

- corrosion of the material.

- fluidity of the material (1)

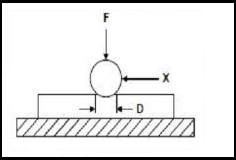

4.7 What does the symbol ‘X’ denote in the Brinell hardness test shown in FIGURE 4.7 below?

FIGURE 4.7

- Ball diameter

- Hardness number

- Test piece

- Force applied (1)

4.8 Which ONE of the following engineering materials is a thermo-hardened composite?

- Teflon

- Bakelite

- Bronze

- White metal (1)

4.9 What would the spindle speed be, if you were milling a material that has a cutting speed of 35 m/min with a cutter of 50 mm in diameter?

- 233 r/min

- 223 r/min

- 322 r/s

- 232 r/min (1)

4.10 Which ONE of the following indexing methods can be used to mill an angle of 41º 28’?

- Angular indexing

- Simple indexing

- Rapid indexing

- None of the above (1)

4.11 Which of the following is the definition of pressure?

- Pressure is the force acting on an object in a downward direction.

- Pressure is the force per unit area applied in a direction parallel to the surface

- Pressure is the force per unit area applied in a direction perpendicular to the surface

- Pressure is the force per unit volume applied in a direction parallel to the surface (1)

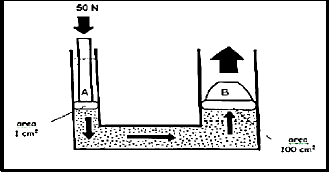

4.12 The hydraulic system shown in FIGURE 4.12 below is used to lift a load. What is the pressure exerted on piston A? Given: the area of piston A is 1 cm².

FIGURE 4.12

- 50 Pa

- 500 Pa

- 5 000 Pa

- 500 000 Pa (1)

4.13 Determine the width of a parallel key if the diameter is 36 mm.

- 8 mm

- 10 mm

- 9 mm

- 36 mm (1)

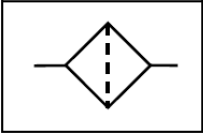

4.14 Identify the symbol, shown in FIGURE 4.14 below, which relates to a pneumatic system.

FIGURE 4.14

- Valve

- Fitter

- Compressor

- Motor (1)

[14]

QUESTION 5: TERMINOLOGY (LATHE AND MILLING MACHINE) (SPECIFIC)

5.1 Describe the function of the following centre lathe components:

5.1.1 Chuck (1)

5.1.2 Tool post (1)

5.1.3 Compound slide (1)

5.2 State the TWO classes of milling cutters and give ONE example of each. (4)

5.3 A 55 mm diameter shaft, 450 mm long, must be taper-turned with an included angle of 8.5º for a length of 250 mm. Calculate the small diameter of the taper.

(4)

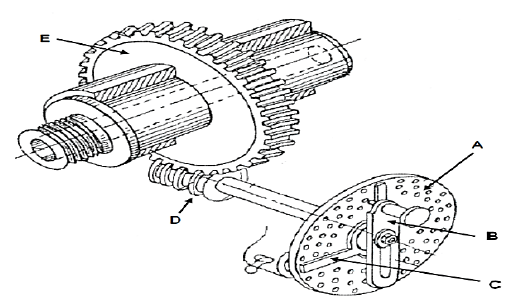

5.4 FIGURE 5.4 shows a drawing of a dividing head of a milling machine.

FIGURE 5.4

5.4.1 Label parts A–E. (5)

5.5 Calculate the lead of a triple start thread with a 1,75 mm pitch. (2)

[18]

QUESTION 6: TERMINOLOGY (SPECIFIC)

6.1 Explain the function of the following milling machine components:

6.1.1 Dividing head (1)

6.1.2 Index plate (1)

6.1.3 Sector arm (1)

6.2 Explain, step by step, the procedure used to cut an external metric V-screw thread with a pitch of 2 mm on a centre lathe using the compound slide method. (5)

6.3 Define the term indexing as applied to milling processes. (1)

6.4 State the TWO milling methods. (2)

6.5 Calculate the differential indexing of a gear with 113 teeth, determining:

6.5.1 The indexing required (Hint: Choose 120 divisions) (3)

6.5.2 The change gears required for the dividing head (5)

6.5.3 What is the meaning of the positive (+) sign and the negative (-) sign for the change of gears? (1)

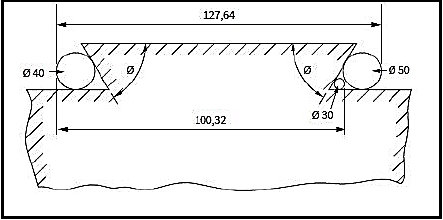

6.6 The drawing in FIGURE 6.7 shows two precision rollers placed in an external dovetail.

FIGURE 6.7

Calculate the angle θ using the values given in the drawing. (6)

6.7 State TWO disadvantages/constraints experienced when balancing is done practically. (2)

[28]

QUESTION 7: TOOLS AND EQUIPMENT (SPECIFIC)

7.1 With the aid of neat sketches, highlight the difference between the following testers:

7.1.1 Brinell hardness tester (3)

7.1.2 Rockwell hardness tester (3)

7.2 State THREE ways in which materials hardness is measured. (3)

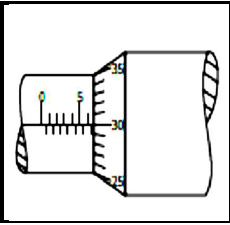

7.3 Determine the pitch from the screw thread micrometres shown in FIGURE 7.3.

FIGURE 7.3 (2)

7.4 Draw the depth micrometre reading of 41,25 mm. (2)

[13]

QUESTION 8: FORCES (SPECIFIC)

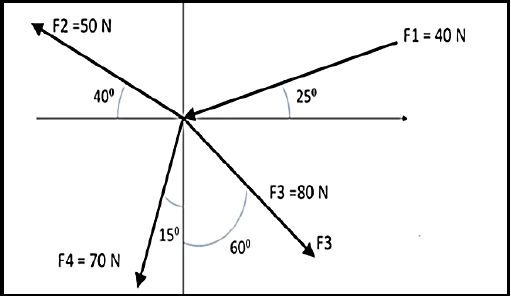

8.1 FIGURE 8.1 below shows a system of forces with four concurrently applied forces. Calculate the magnitude and direction of the equilibrant of this system of forces.

FIGURE 8.1 (12)

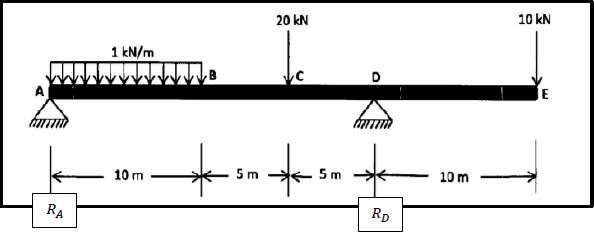

8.2 The diagram in FIGURE 8.2 below shows a beam with two vertically applied point loads of 10 kN and 20 kN and also a 1 kN/m uniformly distributed load on it.

FIGURE 8.2

Calculate the magnitude of reactions RA and RD. (5)

8.3 A tensile force of 10 kN is applied to a round steel bar with a diameter of 20 mm and a length of 2 m. Young’s modulus of elasticity for this steel is 200 GPa.

Calculate:

8.3.1 The stress (4)

8.3.2 The extension due to the tensile force (4)

8.4 Draw and label the stress/strain diagram. (6)

8.5 What does the abbreviation FOS stand for in relation to stress calculations? (1)

8.6 Define the term Young’s modulus. (1)

[33]

QUESTION 9: MAINTENANCE (SPECIFIC)

9.1 What is the purpose of the following thermo-hardened composites?

9.1.1 Bakelite (2)

9.1.2 Glass fibre (2)

9.1.3 Carbon fibre (2)

9.2 Why is it essential to use a cutting fluid on a milling or centre lathe? (1)

9.3 List THREE mechanical drives generally used in engineering. (3)

9.4 Give TWO reasons for using carbon fibre in the manufacture of bicycle frames. (2)

9.5 In tabulated form compare ONE property and ONE use of the following thermoplastic materials:

9.5.1 PVC (2)

9.5.2 Vesconite (2)

9.5.3 Nylon (2)

[18]

QUESTION 10: JOINING METHODS (SPECIFIC)

10.1 A product inspector inspects gears that have been manufactured, he finds out that there is some uncertainty regarding the gear specifications. You are requested to calculate the following gear terms of a straight-tooth gear with 60 teeth and a module of 4.

Determine, by means of calculations, the following:

10.1.1 The pitch-circle diameter (2)

10.1.2 The addendum (2)

10.1.3 The clearance (2)

10.1.4 The dedendum (2)

10.1.5 The outside diameter of the gear (2)

10.2 FIGURE 10.2 below shows a cutting tool suitable for cutting left-hand square screw thread, in position.

FIGURE 10.2 (4)

Label parts A–D.

10.3 Why would a multi-start thread be preferred mostly to a single start thread? (2)

10.4 Describe what is meant by screw thread fit. (2)

[18]

QUESTION 11: SYSTEMS AND CONTROL (SPECIFIC)

11.1 Describe the principle of operation of a gear drive. (2)

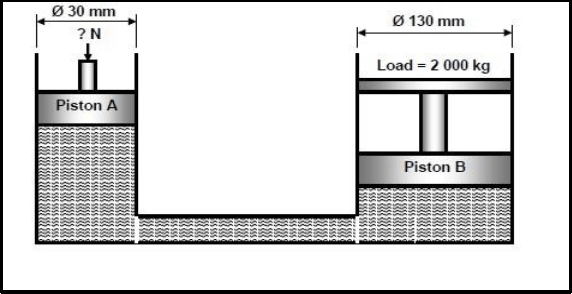

11.2 A hydraulic system is being used to lift goods when loading it into trucks. The specifications of the system are diagrammatically presented in FIGURE 11.2

Calculate the following:

11.2.1 Convert the 2 000 kg mass into weight in Newtons (2)

11.2.2 The fluid pressure in the hydraulic system when the system is in equilibrium. (4)

11.2.3 The force that needs to be exerted onto piston A (4)

11.2.4 State ONE application of the system above. (1)

11.3 Define what is meant by velocity ratio. (2)

11.4 A power saw’s motor has a pulley, 135 mm in diameter, that turns at

1 200 rpm. The speed at which the driven pulley drives the saw blades is 395 rpm. Calculate the diameter of the driven pulley. (3)

11.5 Give THREE applications where pneumatics systems are used. (3)

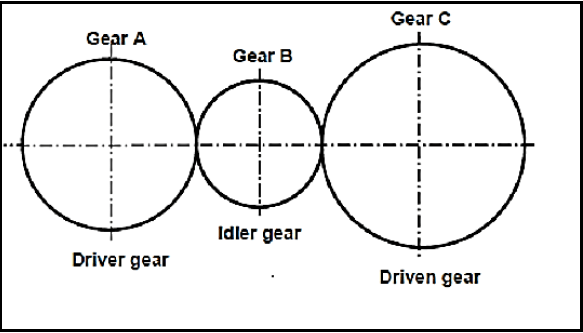

11.6 The gear system in FIGURE 11.6 below is used to control a hoisting device. The driver gear has 56 teeth and rotates at 700 r/min. The idler gear used to change the direction, rotates at 980 r/min. The driven gear has 64 teeth.

FIGURE 11.6

Calculate the:

11.6.1 Number of teeth on the idler gear (3)

11.6.2 The rotation frequency of the driven gear (3)

11.6.3 In which direction will the driven gear rotate if the driver gear rotates anti-clockwise? (1)

[28]

TOTAL: 200

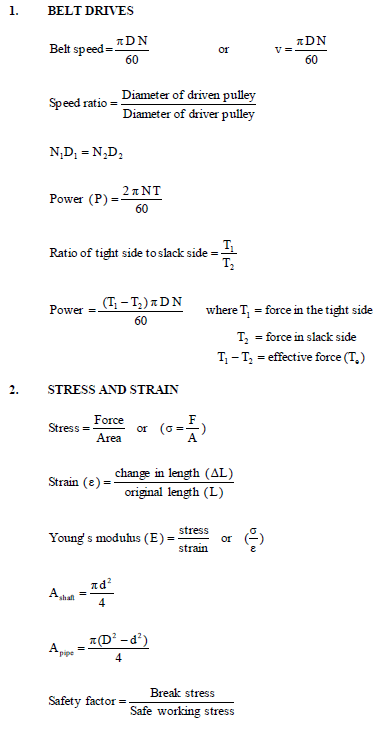

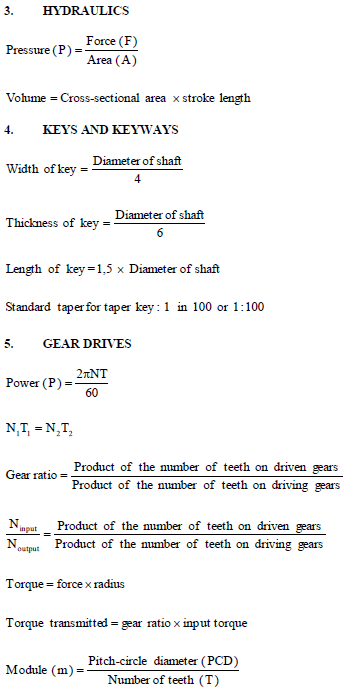

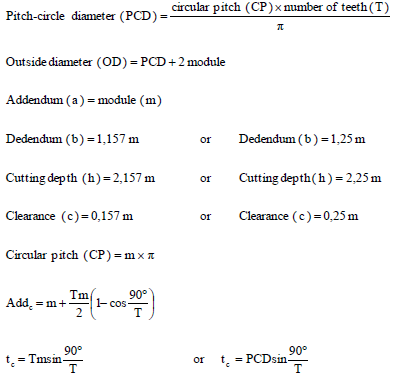

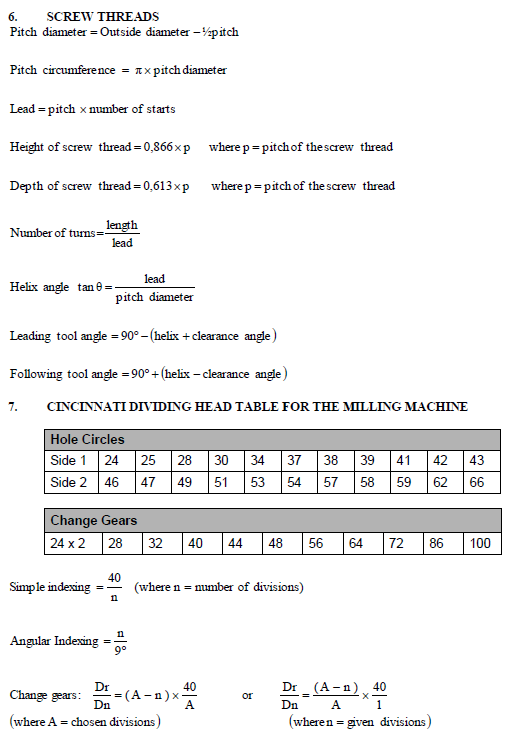

FORMULA SHEET FOR MECHANICAL TECHNOLOGY (FITTING AND MACHINING)