Mechanical Technology: Automotive Grade 12 Questions - NSC Exams Past Papers and Memos September 2019 Preparatory Examinations

Share via Whatsapp Join our WhatsApp Group Join our Telegram GroupINSTRUCTIONS AND INFORMATION

- Write your NAME on the ANSWER BOOK.

- Read ALL the questions carefully.

- Answer ALL the questions.

- Number the answers correctly according to the numbering system used in this question paper.

- Start EACH question on a NEW page.

- Show ALL calculations and units. Round off final answers to TWO decimal places.

- You may use a non-programmable scientific calculator and drawing instruments.

- The value of gravitational force should be taken as 10 m/s2.

- All dimensions are in millimetres, unless stated otherwise in the question.

- A formula sheet is attached to the question paper.

- Write neatly and legibly.

- Use the criteria below to assist you with your time management.

QUESTION | CONTENT | MARKS | TIME |

Generic | |||

1 | Multiple-choice questions | 6 | 6 minutes |

2 | Safety | 10 | 10 minutes |

3 | Materials | 14 | 14 minutes |

Specific | |||

4 | Multiple-choice questions | 14 | 10 minutes |

5 | Tools and Equipment | 23 | 20 minutes |

6 | Engines | 28 | 25 minutes |

7 | Forces | 32 | 25 minutes |

8 | Maintenance | 23 | 20 minutes |

9 | Systems and Control (Automatic Gearbox) | 18 | 20 minutes |

10 | Systems and Control (Axles, Steering Geometry and Electronics) | 32 | 30 minutes |

TOTAL | 200 | 180 minutes | |

QUESTIONS

QUESTION 1: MULTIPLE-CHOICE QUESTIONS (GENERIC)

Various options are provided as possible answers to the following questions. Choose the correct answer and write only the letter (A–D) next to the question numbers (1.1–1.6) in the ANSWER BOOK, for example 1.7 A.

1.1 Which of the following is NOT a basic first aid treatment?

- Examination

- Diagnosis

- Operate

- Basic comfort and safety (1)

1.2 Which ONE of the following items of personal protective (PPE) equipment is applicable when performing arc welding?

- Welding helmet

- Welding goggles

- Hard hat

- Dust mask (1)

1.3 Which of the following is a safety precaution in relation to the use of a bench grinder?

- The tool rest must not be more than 3 mm from the grinding wheel.

- Make sure the chuck is correctly tightened.

- Stand to the side when switching on the machine.

- Do not wear safety goggles. (1)

1.4 What is the colour of an oxygen gas cylinder?

- Maroon

- Grey

- Green

- Black (1)

1.5 Stopping devices on machinery are normally … in colour.

- red

- green

- black

- orange (1)

1.6 What is the maximum thickness of sheet metal that can be cut using a hand guillotine?

- 3,2 mm

- 1,6 mm

- 1,2 mm

- 2,1 mm (1) [6]

QUESTION 2: SAFETY (GENERIC)

2.1 Give TWO reasons why it is important to wear a helmet during arc welding. (2)

(2)

2.2 State TWO safety measures to be used when using the angle grinder. (2)

2.3 What is the maximum gap that the tool rest should be set from the grinding wheel of a bench grinder? (1)

(1)

2.4 Give THREE safety rules to be applied when using a band saw. (3)

2.5 State TWO safety precautions that must be observed when handling gas cylinders.

(2) [10]

QUESTION 3: MATERIALS (GENERIC)

3.1 Explain what you understand about quenching during the heat treatment process. (3)

3.2 Why is brine better than fresh water in quenching heat-treated materials? (2)

3.3 State the purpose for case-hardening mild steel. (3)

3.4 Name TWO methods by which case-hardening can be done. (2)

3.5 Explain the difference between annealing and normalising. (4) [14]

QUESTION 4: MULTIPLE-CHOICE QUESTIONS (SPECIFIC)

Various options are provided as possible answers to the following questions. Choose the correct answer and write only the letter (A–D) next to the question number (4.1–4.14) in your ANSWER BOOK, for example 4.15 A.

4.1 FIGURE 4.1 shown below is a card type compression tester. What is the advantage of using this type of compression tester over the conventional type?

FIGURE 4.1

- Gives accurate readings

- Easy to use

- The pressure readings are printed on the cards which serves as evidence on the state of the combustion chamber

- It can also determine the percentage leakage of a cylinder and the area where the leakage occurs (1)

4.2 What is the function of the compression release valve in a compression tester?

- To increase the pressure in the cylinder

- To reset the tool by relieving it of any built-in pressure caused by a previous test

- To prevent the vehicle engine from running during the process of the compression testing

- To control the pressure from exceeding the safety limit (1)

4.3 A bubble gauge is used to test the following wheel alignments except …

- toe-in and toe-out of a vehicle.

- king pin inclination.

- caster.

- camber. (1)

4.4 Identify the type of engine cylinder configuration shown below.

- Crankshaft for horizontally opposed engine

- Crankshaft for V-engine

- W-engine

- In-line crankshaft for an in-line engine (1)

4.5 The hissing sound heard from the exhaust manifold during a cylinder leakage testing indicates that …

- the inlet valve is worn out.

- the piston rings are worn out.

- the exhaust valve is worn out.

- there is a crack in the cylinder head. (1)

4.6 Which of the following methods is not applicable in raising the compression ratio in an internal combustion engine?

- Increase the bore of the cylinder

- Fit piston with suitable higher crown

- Machine metal from cylinder head

- Increasing the size of the Gudgeon pin (1)

4.7 Calculate the compression ratio of an engine with a bore of 91 mm and a stroke of 83 mm if its combustion chamber volume is 60 cm3.

- 12 : 1

- 10,5 : 1

- 8 : 1

- 10 : 1 (1)

4.8 Diode/rectifier is an important part of an alternator during the production electric current. What is the main function of the diode/rectifier in the process?

- Generate electricity

- Permit the flow of current only in one direction

- Prevent flow of current

- Increase the flow of current (1)

4.9 Coolant temperature sensor is a device fitted into the water jacket to measure the engine coolant temperature and supply the signal to the engine control module (ECM). How does this influence the performance of a vehicle engine?

- Controls the operation of the water pump

- Controls the pressure of the oil pump

- Controls the gear shift in an automatic transmission system as the coolant temperature rises

- Controls the rpm (revolution per minute) of an engine depending on the coolant temperature (1)

4.10 How does a negative camber alignment setting affect the tyre of a car?

- It wears the tyre from the outside

- It wears the tyre evenly

- It makes the tyre last longer

- It wears the tyre from the inside (1)

4.11 In an air induction system, which of the following is the correct function of the idle speed control (ISC) valve?

- Gives information to the engine control module (ECM) about the oxygen level in the exhaust gas outlet

- Regulates the fuel pressure in the fuel system

- Controls the volume of air that is allowed to by-pass the closed throttle valve for effective idling at different engine temperatures

- Increases the pressure in the inlet manifold at high engine temperature (1)

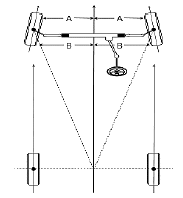

4.12 Identify the type of alignment setting in the vehicle below.

- Toe-out

- Positive caster

- Toe-in

- Negative caster (1)

4.13 Which of the following options is not a method of increasing the output frequency of an alternator?

- Increasing the magnetic fields

- Increase the number of diodes/rectifiers

- Increase the turns of wire on the stationary coil

- Increase the rotational frequency of the rotor (1)

4.14 The forced induction system developed as a result of the combination of turbo charger and super charger on the same engine is called …

- twin-charging

- full charging

- high charging

- boost (1) [14]

QUESTION 5: TOOLS AND EQUIPMENT (SPECIFIC)

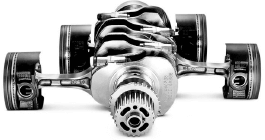

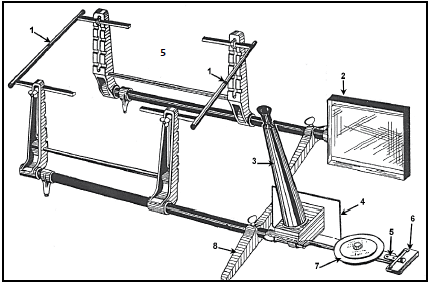

5.1 The figure below is an alignment equipment used in automotive workshops. Answer the questions that follow.

FIGURE 5.1

5.1.1 Identify the equipment in FIGURE 5.1. (1)

5.1.2 Label parts 1–8. (8)

5.1.3 Describe the function of the equipment. (1)

5.2 State any FOUR safety rules that must be followed in order to achieve accurate results during the process of using emission gas analysers to test the exhaust gases of a car. (4)

5.3 In point form describe the set-up procedure when using a card type compression tester. (6)

5.4 What is the main purpose of the following tools in an automotive workshop?

5.4.1 Gas analyser (1)

5.4.2 Wheel balancer (1)

5.4.3 Compression tester (1) [23]

QUESTION 6: ENGINE (SPECIFIC)

6.1 Explain the purpose of a vibration damper in an internal combustion engine. (2)

6.2 List TWO types of vibration dampers used in an engine. (2)

6.3 List TWO factors responsible for crankshaft vibration in an internal combustion engine. (2)

6.4 State THREE factors that determine the configuration of an engine. (3)

6.5 List any THREE types of engine cylinder configurations. (3)

6.6 Explain the principle of operation of a working turbocharger. (3)

6.7 Give THREE disadvantages that are commonly associated with a turbocharger. (3)

6.8 What is the main difference between a turbocharger and a supercharger? (2)

6.9 List any THREE types of superchargers that are used with internal combustion engines. (3)

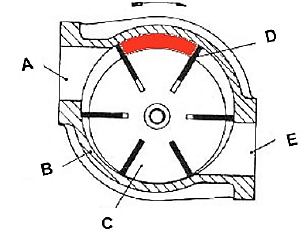

6.10 A supercharger is shown in FIGURE 6.10 below. Label parts A–E.

FIGURE 6.10 (5) [28]

QUESTION 7: FORCES (SPECIFIC)

7.1 Define the term compression ratio. (2)

7.2 A compression ignition engine (CI) has a cylinder diameter of 105 mm, a stroke length of 112 mm and a clearance volume of 98 cm3. Calculate the compression ratio of the engine. (6)

7.3 If the engine in QUESTION 7.2 undergoes overhauling and the bore was increased to 110 mm in the process in order to fit in a new but bigger piston, what will be the new compression ratio of the engine? (4)

7.4 What do you understand by indicated power of an engine? (2)

7.5 Briefly explain the application and use of each of the following tools used in automotive workshop:

7.5.1 Electric dynamometer (3)

7.5.2 Chassis dynamometer (3)

7.6 The following data was recorded during a test carried out on a four-stroke, four-cylinder petrol engine:

Mean effective pressure on the piston: 1600 kPa

Length of stroke: 92 mm

Cylinder bore: 99 mm

Revolutions per minute: 4600 rpm

Torque: 280 Nm @ 4200 rpm

Number of cylinders: 4

Calculate the following:

7.6.1 Indicated power in kW (7)

7.6.2 The brake power in kW (3)

7.6.3 Mechanical efficiency (2) [32]

QUESTION 8: MAINTENANCE (SPECIFIC)

8.1 A car exhaust gas was analysed and it was discovered that there was a high hydrocarbon reading.

8.1.1 State THREE possible causes that may be responsible for the high hydrocarbon reading. (3)

8.1.2 Give THREE necessary measures that need to be taken to correct the faults. (3)

8.1.3 Name TWO other gases that may be analysed during the process of exhaust gas analysing. (2)

8.2 During the process of compression testing on a 4-cylinder SI engine, it was discovered that one of the cylinders had an unusual low reading. What will be

the next step to verify if the cylinder is leaking or not? (1)

8.3 Explain the procedure to follow when conducting a cylinder leakage test in an internal combustion engine. (7)

8.4 State TWO possible faults, their possible causes and the corrective measures that needs to be taken to repair the possible faults when doing a cylinder

leakage test. (6)

8.5 Why must radiator cap pressure testing be done? (1) [23]

QUESTION 9: SYSTEMS AND CONTROL (AUTOMATIC GEARBOX) (SPECIFIC)

9.1 Briefly explain the principle of operation of a torque converter. (5)

9.2 What is the function of the following components in an automatic transmission system of a vehicle?

9.2.1 Torque converter (2)

9.2.2 Brake bands (2)

9.2.3 Hydraulic pistons (2)

9.2.4 Oil pump (2)

9.3 Briefly explain the following states of a torque converter in operation:

9.3.1 Stall speed (1)

9.3.2 Increasing speed (1)

9.4 What kind of oil is used in automatic transmission? (1)

9.5 Give TWO methods of cooling oil in an automatic transmission. (2) [18]

QUESTION 10: SYSTEMS AND CONTROL (AXLES, STEERING GEOMETRY AND ELECTRONICS) (SPECIFIC)

10.1 Briefly explain the purpose of the following alignment applications in vehicles:

10.1.1 Toe-in (2)

10.1.2 Toe-out (2)

10.1.3 Ackermann principles (2)

10.2 What type of alignment can be responsible for the tyre wear below? (1)

(1)

10.3 State the functions of the following steering angles:

10.3.1 Camber (2)

10.3.2 Caster (2)

10.3.3 King pin inclination (2)

10.4 List FOUR factors that must be taken into account before wheel alignment can be checked or adjusted.(4)

10.5 Name the TWO types of wheel imbalances. (2)

10.6 What is the function of an electric fuel pump? (2)

10.7 Name TWO types of electric fuel pumps. (2)

10.8 Give THREE advantages of an electric fuel pump. (3)

10.9 Name THREE factors that determine the injection quantity. (3)

10.10 Give THREE advantages of an alternator. (3) [32]

TOTAL: 200

FORMULA SHEET FOR MECHANICAL TECHNOLOGY (AUTOMOTIVE)