AGRICULTURAL TECHNOLOGY GRADE 12 QUESTIONS - NSC EXAMS PAST PAPERS AND MEMOS MAY/JUNE 2021

Share via Whatsapp Join our WhatsApp Group Join our Telegram GroupAGRICULTURAL TECHNOLOGY

GRADE 12

NATIONAL SENIOR CERTIFICATE EXAMINATIONS

MAY/JUNE 2021

INSTRUCTIONS AND INFORMATION

- GENERAL INSTRUCTIONS AND INFORMATION

1.1 This question paper consists of TWO sections, namely SECTION A and SECTION B.

1.2 BOTH sections are COMPULSORY.

1.3 Answer ALL the questions in the ANSWER BOOK.

1.4 Number the answers correctly according to the numbering system used in this question paper.

1.5 You may use a non-programmable calculator.

1.6 Write neatly and legibly. - SECTION A: SHORT QUESTIONS

2.1 This section consists of THREE questions.

2.2 Follow the instructions when answering the questions. - SECTION B: STRUCTURED LONG QUESTIONS

3.1 This section consists of FIVE questions.

3.2 Start EACH question on a NEW page.

SECTION A

QUESTION 1

1.1 Various options are provided as possible answers to the following questions. Choose the answer and write only the letter (A–D) next to the question numbers (1.1.1 to 1.1.10) in the ANSWER BOOK, e.g. 1.1.11 D.

1.1.1 … cameras are installed on drones to do surveillance work at night.

- Seismic

- Radar

- Infrared

- Doppler (2)

1.1.2 A … is used to load large round bales safely onto a truck.

- pulley

- trestle hoist

- loading ramp

- front-end fork loader (2)

1.1.3 device installed in a solar charger system that prevents the battery from overcharging:

- Multimeter

- Transformer

- Regulator

- Inverter (2)

1.1.4 … is NOT associated with the running expenses of a tractor.

- Depreciation

- Fuel

- Labour

- Supervising (2)

1.1.5 … is a term associated with agriculture, where all farm equipment and spares must comply with certain common requirements.

- Precision farming

- Standardisation

- Mechanisation

- Production (2)

1.1.6 A material that can be used effectively as a seal around the door of a cold storage room:

- Vesconite

- Fibre glass

- Teflon

- Rubber

(2)

1.1.7 The … determines the volume of the gas flow when welding with an oxyacetylene set.

- cutting lever

- size of the nozzle

- size of the cylinders

- flashback arrester(2)

1.1.8 The teeth of this type of gear run at an angle across the outer circumference of the gear:

- Ratchet gear

- Spur gear

- Ring gear

- Helical gear

(2)

1.1.9 The … can be used effectively in a chain drive system.

- V-belt

- sprocket

- fishbone gear

- worm gear

(2)

1.1.10 … is NOT a function of GPS navigation systems in modern combine harvesters.

- Yield monitoring

- Autonomous steering

- Identifying a mechanical problem

- Determining of position

(2)

1.2 Change the UNDERLINED word(s) in each of the following statements to make them TRUE. Write only the word next to the question numbers (1.2.1 to 1.2.5) in the ANSWER BOOK, e.g. 1.2.6 Tractor.

1.2.1 Hearing loss is associated with long work shifts, excessive workload and harassment. (2)

1.2.2 Shift the clutch to neutral after stopping a tractor when hitching an implement. (2)

1.2.3 Chromium as an alloy element in stainless steel decreases weldability. (2)

1.2.4 The catalyst and accelerator used in glass fibre repairs should always be stored separately to avoid poisoning. (2)

1.2.5 The hammers of a hammer mill must be replaced regularly to prevent vibration. (2)

1.3 Choose a word/term from COLUMN B that matches the description in COLUMN A. Write only the letter (A–H) next to the question numbers (1.3.1 to 1.3.5) in the ANSWER BOOK, e.g. 1.3.6 J.

| COLUMN A | COLUMN B |

| 1.3.1 A major factor to consider when welding in the overhead oxyacetylene position 1.3.2 Removes the melted metal when doing plasma cutting 1.3.3 Synthetic material used for the manufacturing of hygienic gloves 1.3.4 Equipment that is used to determine the moisture content of soil 1.3.5 Technology that is used to determine areas of stunted growth in a maize field |

|

(5 x 2) (10)

TOTAL SECTION A: 40

SECTION B

QUESTION 2: MATERIALS AND STRUCTURES

Start this question on a NEW page.

2.1 Stainless steel, mild steel, copper and aluminium are all metals that are used on a farm in different applications.

2.1.1 Which ONE of the metals above can be used to manufacture water pipes for farmhouses? (1)

2.1.2 Give a reason why the metal named in QUESTION 2.1.1 will be the most suitable for this application. (1)

2.1.3 Which joining method must be used to join two copper pipes permanently? (1)

2.1.4 Name the metal that will be best for transporting milk in a dairy. (1)

2.1.5 Give a reason why the metal named in QUESTION 2.1.4 would be most suitable for this specific application. (1)

2.1.6 Which joining method will be suitable for permanently joining stainless steel? (1)

2.1.7 Name a metal that will be the most economical for the manufacturing of a farm gate. (1)

2.1.8 Name a substance that can easily corrode copper. (1)

2.1.9 Name the metal that is commonly used in the food industry for storing purposes.(1)

2.2 PVC pipes that are joined with PVC weld can sometimes leak. Recommend THREE preparation procedures that must be followed before the adhesive is applied to ensure an effective joint. (3)

2.3 The picture below shows an electric fence.

2.3.1 Describe the earth leakage system of the electrical fence. (6)

2.3.2 Name the type of wire that should NOT be used in the construction of an electric fence. (1)

2.3.3 State TWO daily activities that the farmer must perform to maintain an electric fence properly. (2)

2.4 Explain why you would recommend Vesconite as the best material to use in the manufacturing of bushes. (5)

2.5 Name ONE electrical property of Teflon and give a reason for your answer. (2)

2.6 Name FIVE properties applicable to the safety screens used on a combine harvester. (5)

2.7 Give TWO reasons for using brass instead of copper in the manufacturing of electrical connections. (2)

[35]

QUESTION 3: ENERGY

Start this question on a NEW page.

3.1 Name TWO alternative energy sources that use a turbine and a generator to generate electricity. (2)

3.2 The picture below shows a 3 000-watt photovoltaic solar panel system.

3.2.1 How many of these systems do you need to provide sufficient power to a 6 kW submersible pump? (1)

3.2.2 Determine whether the panels should be connected in parallel or series. Give a reason for your answer. (2)

3.2.3 Give a reason for the use of silicon in the manufacturing of the solar cells. (1)

3.2.4 Name the layer of the solar panel that carries negative electrons. (1)

3.2.5 What can be done to ensure that electricity is also available during the night if you use a solar power electric system? (1)

3.2.6 Name THREE applications of electric solar panels on a game farm. (3)

3.3 State FOUR advantages of a geothermal power station. (4)

3.4 Name FOUR factors that must be considered when choosing a suitable location for installing a wind turbine on a farm. (4)

3.5 Name the process that is used to manufacture ethanol. (1)

[20]

QUESTION 4: SKILLS AND CONSTRUCTION PROCESSES

Start this question on a NEW page.

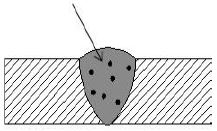

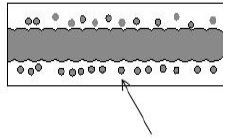

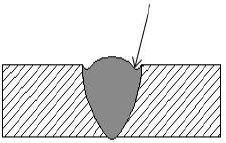

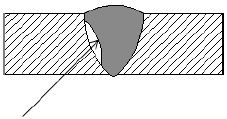

4.1 The table below shows four welding defects. Redraw the table in your ANSWER BOOK and write down the answers to QUESTIONS 4.1.1 to 4.1.8.

| ILLUSTRATION | NAME OF THE WELDING DEFECT | GIVE THE POSSIBLE CAUSES |

. | 4.1.1 | 4.1.2 |

. | 4.1.3 | 4.1.4 |

. | 4.1.5 | 4.1.6 |

. | 4.1.7 | 4.1.8 |

(8)

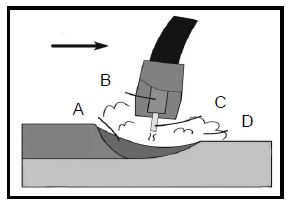

4.2 The illustration below shows the MIG welding process. Label A–D. (4)

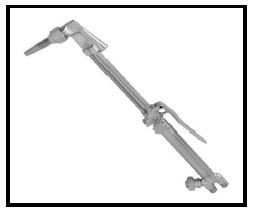

4.3 The image below shows an oxyacetylene cutting apparatus.

4.3.1 Name TWO types of materials that can be cut with the above apparatus.(2)

4.3.2 Explain FIVE steps to follow when making a straight cut on a 10 mm thick mild steel sheet using the oxyacetylene cutting apparatus. (5)

4.3.3 Give THREE tips to ensure a high quality welding joint when oxy-acetylene welding is done in the overhead welding position.(3)

4.4

Scenario

|

Use the information above and draw a neat design sketch of the work bench.

Marks will be allocated as follows:

| Design | 2 |

| Scale (Application) | 1 |

| Dimensions | 2 |

| Neatness | 1 |

4.5 Name a gas that could be used during plasma cutting to remove the melted metal. (1)

4.6 Use a table and compare the inverter welding machine with the MIG welding machine. (6)

[35]

QUESTION 5: TOOLS, IMPLEMENTS AND EQUIPMENT

Start this question on a NEW page.

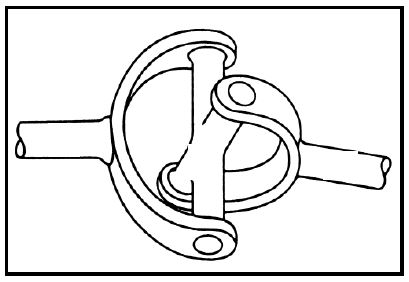

5.1 The sketch below shows three components working together in a system.

5.1.1 Identify the component in the sketch that serves as a connection between the parts. (1)

5.1.2 Name the substance that is used to lubricate the component identified in QUESTION 5.1.1. (1)

5.1.3 State ONE application of the component identified in QUESTION 5.1.1. (1)

5.1.4 Name TWO mechanisms installed in the drive system of a four-wheel drive vehicle that allows disconnection of drive to the front wheels and state ONE advantage of EACH mechanism. (4)

5.2 Indicate the type of hydraulic cylinder that can be used to activate the fork of a bale-handling mechanism when forced movement in reverse directions is required. (1)

5.3 Give the function of the lining on the clutch plate as found in the clutch assembly of a vehicle.(1)

5.4 Name TWO advantages of the differential lock as found on a tractor. (2)

5.5 Some universal joint bearings are manufactured without a grease nipple. Name ONE advantage of such a bearing. (1)

5.6 An electrical motor is connected to a centrifugal pump by means of pulleys and a V-belt. The pump pulley has a diameter of 450 mm and the electrical motor has a pulley of 150 mm.

5.6.1 Calculate the pulley ratio of the electrical motor to the pump. (Show ALL calculations.) (3)

5.6.2 Give FOUR reasons why a farmer would prefer V-belt drive systems to flat belt drive systems. (4)

5.6.3 Identify the part installed in the housing of the electrical motor to allow the rotor shaft to rotate freely.(1)

5.7 Blue smoke seen at the exhaust pipe of a tractor indicates oil in the combustion chamber. Give FOUR possible causes of the presence of oil in the combustion chamber of an engine. (4)

5.8 Describe the properties of a functional clutch. (5)

5.9 Name FOUR parts that must be examined on a second-hand tractor before you decide to buy it. (4)

5.10 State the functions of the following parts of a hammer mill:

5.10.1 Hopper (1)

5.10.2 Cyclone (1)

5.11 Give a reason for setting the wheels of a front-end loader to its widest possible position. (1)

5.12 Describe the servicing procedures that must be followed when preparing a combine harvester for the harvesting season. (4)

[40]

QUESTION 6: WATER MANAGEMENT

Start this question on a NEW page.

6.1 Name FOUR important factors that must be considered before deciding on a relevant irrigation method. (4)

6.2 What are the main goals with irrigation scheduling? (3)

6.3 Identify TWO structural problems on the sprinkler shown below that can negatively influence efficiency. (2)

6.4 Name a device that a farmer can use to measure the evaporation tempo in a maize field. (1)

6.5 Draw a labelled freehand sketch of a French water drainage system. Marks will be allocated as follows:

| Design | 1 |

| Drawing | 1 |

| Labels | 4 |

(6)

6.6 List FIVE items that should never be disposed of in a household septic tank system. (5)

6.7 Give THREE reasons why it is essential for a farmer to know how to determine the flow rate in a water pipe delivery system. (3)

6.8 The picture below shows a centre-pivot irrigation system.

6.8.1 Name THREE advantages of centre-pivot irrigation systems. (3)

6.8.2 Which THREE elements are built into the design of a centre-pivot irrigation system to ensure uniform distribution of water along the whole length of the system? (3)

[30]

TOTAL SECTION B: 160

GRAND TOTAL: 200