MECHANICAL TECHNOLOGY(WELDING) GRADE 12 MEMORANDUM - NSC PAST PAPERS AND MEMOS NOVEMBER 2019

Share via Whatsapp Join our WhatsApp Group Join our Telegram GroupMECHANICAL TECHNOLOGY: WELDING AND METALWORK

GRADE 12

NATIONAL SENIOR CERTIFICATE

NOVEMBER 2019

MEMORANDUM

QUESTION 1: MULTIPLE-CHOICE (Generic)

1.1 B ✓(1)

1.2 C ✓ (1)

1.3 A ✓ (1)

1.4 C ✓ (1)

1.5 A ✓ (1)

1.6 C ✓ (1)

[6]

QUESTION 2: SAFETY (Generic)

2.1 Machine safety rule:

- Know how to switch the machine off / emergency stop.✓

- Wear personal protective equipment (PPE). ✓

- Know how to use the machine.✓

- Ensure that all guards are in place. ✓

- No tools lying on the machine. ✓

- Work piece is properly secured. ✓

- Check the condition of the machine. ✓

- Follow manufacture's specifications before operating a machine. ✓

- Operator must have authorization to working on a machine. ✓

- Make sure the machine is not locked out. ✓

- Ensure that the machine setup is correct and safe. ✓

- Ensure that the machine area is clean and safe. ✓

(Any 1 x 1) (1)

2.2 Drill press safety precautions:

- To prevent injuries. ✓

- To improve accuracy. ✓

- To prevent work piece rotating/moving. ✓

- To prevent the drill bit from breaking. ✓

(Any 1 x 1) (1)

2.3 Hydraulic press safety rules:

- Make sure the press is in a good working condition. ✓

- Take notice of the pre-determined maximum pressure of the hydraulic press. ✓

- Make sure the area around the press is clean and free of oil, grease and water. ✓

- Ensure that the platform is rigid and square to the cylinder. ✓

- Ensure that suitable jigs and prescribed equipment is available. ✓

- Check hydraulic pipes for leaks or cracks. ✓

- Check supporting pins are not worn out and fitted properly. ✓

- Check fluid levels. ✓

- Compressive force must be applied at 90° to the object.✓

- Check cable and pulleys on the platform if equipped. ✓

- Correct PPE. ✓

- Pressure gauge must be checked and calibrated. ✓

- Ensure that all guards are in place. ✓

(Any 2 x 1) (2)

2.4 Reasons for wearing surgical gloves:

- To prevent HIV/AIDS or any blood related infections being transmitted✓

- To prevent contamination of the open wounds✓ (2)

2.5 Safe handling of portable electrical equipment:

- Ensure the electrical cord and plug, are in a good condition. ✓

- Ensure all safety guards are in place. ✓

- Ensure that the correct attachments (drill bits, blades etc.) are fixed in the correct way. ✓

- Do not force the machine/equipment.✓

- Operate according to manufacturer instructions. ✓

- Avoid contact with water.✓

- Keep the cable away from heat, oil, sharp edges and moving parts. ✓

- Make sure that the wires don't wrap around each other. ✓

- Avoid dropping the machine. ✓

- Check the condition of the equipment. ✓

(Any 2 x 1) (2)

2.6 Responsibility of employer:

- Provide and maintain working systems, work area, equipment and tools in a safe condition. ✓

- Eliminate or reduce any potential hazard. ✓

- Produce, handle, store and transport goods safely.✓

- Ensure that every person employed complies with the requirements of this OHS Act. ✓

- Enforce measures if necessary in the interest of health and safety. ✓

- Appoint a person who is trained and who have the authority to ensure that the employee takes precautionary measures. ✓

- Inform employees of the hazards to his health and safety attached to any duty or work situation. ✓

- Provide first aid equipment. ✓

(Any 1 x 1) (1)

2.7 Responsibility of employee:

- Pay attention to their own and other people's health and safety. ✓

- Co-operate with the employer regarding the OHS Act. ✓

- Carry out a lawful order given to them. ✓

- Report any situation that is unsafe or unhealthy.✓

- Report all incidents and accidents. ✓

- Not to interfere with any safety equipment or misuse such equipment.✓

- Obey all safety rules. ✓

(Any 1 x 1) (1)

[10]

QUESTION 3: MATERIAL (Generic)

3.1 Filing test:

- Use the right ✓ filing skills. ✓

- File on the tip or edge ✓✓ of the metal.

- By applying chalk ✓ to the file surface. ✓

(Any 1 x 2) (2)

3.2 Purpose of heat treatment of steel:

Heat treatment of steel is done to change ✓ the properties/grain structure ✓ of steel. (2)

3.3 Reasons for tempering hardened steel:

- To reduce ✓ the brittleness ✓ caused by the hardening process.

- To relieve ✓ strain ✓ caused during hardening process.

- To increase ✓ the toughness ✓ of the steel.

- To give hardened work piece a more ✓ fine-grained structure. ✓

(Any 2 x 2) (4)

3.4 Heat treatment processes on steel:

3.4.1 Annealing:

- The steel is heated to the prescribed temperature. ✓

- The steel is soaked at that temperature for the required time. ✓

- The steel is then cooled very slowly to produce maximum softness.✓ (3)

3.4.2 Hardening:

- The steel is heated slightly higher than the upper critical temperature. (AC3) ✓

- The steel is soaked at that temperature for the required time. ✓

- The steel is then rapidly cooled by quenching in rapid cooling medium. ✓(3)

[14]

QUESTION 4: MULTIPLE-CHOICE QUESTIONS (Specific)

4.1 D ✓ (1)

4.2 A ✓ (1)

4.3 C ✓ (1)

4.4 D ✓ (1)

4.5 B ✓ (1)

4.6 D ✓ (1)

4.7 D ✓ (1)

4.8 C✓ (1)

4.9 A ✓ (1)

4.10 C ✓ (1)

4.11 A ✓ (1)

4.12 C ✓ (1)

4.13 B ✓ (1)

4.14 D ✓ (1)

[14]

QUESTION 5: TERMINOLOGY (TEMPLATES) (Specific)

5.1 Abbreviation:

OSU Other ✓ Side Up ✓ (2)

5.2 Plate girder:

Is a combination of plates and angle iron ✓ welded together. ✓(2)

5.3 Purpose of supplementary welding symbols:

To indicate the additional/supplementary information regarding the weld. ✓ (1)

5.4 Fusion welds:

- Spot welding ✓

- Projection ✓

- Seam welding ✓

- Foil seam welding ✓

- Flash or resistance butt ✓

- Gas welding ✓

- MIG/MAGS Welding ✓

- Arc welding ✓

(Any 4 x 1) (4)

5.5 Supplementary weld symbols:

5.5.1 Grind ✓ (1)

5.5.2 Flame ✓ (1)

5.5.3 Machine ✓ (1)

5.5.4 Flush ✓ (1)

5.5.5 Convex ✓ (1)

5.6 Material calculations:

Mean diameter = Outside diameter - plate thickness

=300 - 20

= 280 mm

Mean circumference = π x mean diameter

= π x 280

= 879.65 mm, (7)

5.7 Weld dimensions:

- 30°: the included angle in degree ✓

- 5: root gap or root opening in mm ✓ (2)

[23]

QUESTION 6: TOOLS AND EQUIPMENT (Specific)

6.1.1 Power saw/Reciprocating saw:

- The blade is tensioned in the frame ✓ and cuts in a forward stroke and the blade is lifted in the backward (reciprocating) motion. ✓

- The blade assembly is raised and lowered ✓ by hydraulic controls to ensure that the cutting pressure is optimum. ✓ (4)

6.1.2 Manual guillotine:

- This guillotine is operated by a foot/hand pedal/lever that activates a pressure plate/blade guard. ✓

- The blade cuts the material. ✓

- The cut material is ejected at the back of the machine. ✓

- Extension bars lengthen the work surface and support longer pieces of material. ✓(4)

6.1.3 Horizontal pyramid rolls:

- Electrical/Power or hand driven. ✓

- The rollers are arranged so that, when viewed from the side, they give the impression of a pyramid. ✓

- All rollers are mounted in a horizontal position, with the bottom two fixed and rotating in unison. ✓

- The top roller is adjustable (up or down); applying downward pressure on the metal plate being rolled that will cause it to deflect and form the round shape. ✓ (4)

6.2 Bench Grinder:

- To sharpen cutting tools and drill bits. ✓

- To removing rough edges. ✓

- To removing excess material. ✓ (3)

6.3 Materials that can be cut with a plasma cutter:

- Mild steel ✓

- Alloy steels ✓

- Stainless steels ✓

- Non-ferrous metals ✓

(Any 3 x 1) (3)

[18]

QUESTION 7: FORCES (Specific)

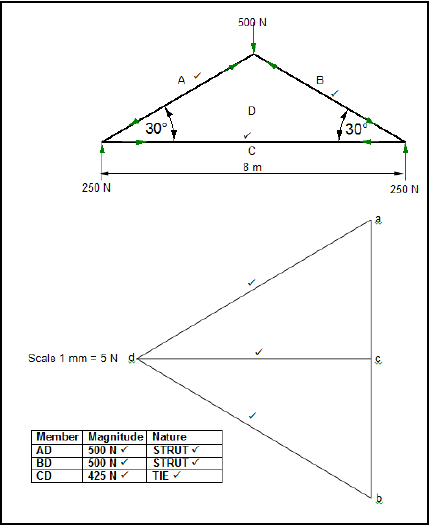

7.1 Frame works: (12)

7.2

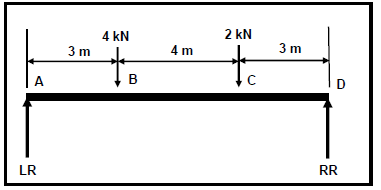

7.2.1 Reactions at supports RL and RR:

Take moments about RR:

LR x 10 = (4 x 7)+(2 x 3)

LR = 3,4 kN

Take moments about LR:

RR x 10 =(2 x 7)+(4 x 3)

RR = 2,6 kN (6)

7.2.2 Bending moments:

BMA = 0 3,4 0 kN.m A

BMB = (3 x 3,4) - (0 x 4) 10,2 kN.m B

BMC = (7 x 3,4) - (4 x 4) - (0 x 2) 7,8 kN.m C

BMD = (10 x 3,4) - (7 x 4) - (3 x 2) + (0 x 2,6) 0 kN.m D (4)

7.2.3 Shear forces:

SFA = 0kN A OR UFA = 3,4kN

SFB = 3,4- 4 -0,6 kN

SFC = 3,4 - (4 + 2) -2,6 kN

SFD = 0kN OR UFD 2,6kN (4)

7.2.4 SF and BM diagrams: (6)

7.3 Stress and Strain:

7.3.1 Stress:

A = πd 2

4

= π x 0,012

4

A = 7,85 x 10-5 m2

Stress = Load

Area

= 50 x 10 3

7,85 x 10-5

= 636942675,2 Pa

= 636,94MPa(5)

7.3.2 Strain:

Strain = ΔL

OL

= 0,6 x 10-3

20

= 3 x 10-5 (3)

7.3.3 Final length:

Final length = OL + ΔL

= 20 + 0,6 + 10-3

= 20,0006m (2)

7.3.4 Young’s modulus:

E = Stress

Strain

E = 636,94 x 106

3 x 10-5

E = 2,1231 x 1013 Pa

E 21231,33 GPa

QUESTION 8: JOINING METHODS (Inspection of weld) (Specific)

8.1 Causes of arc-welding defects:

8.1.1 Undercutting:

- To high welding current ✓

- Electrode at incorrect angle ✓

- Excessive weaving ✓

- Arc length too long ✓

- Travel speed to high ✓

(Any 2 x 1) (2)

8.1.2 Causes of slag inclusion:

- Defective consumables. ✓

- Inadequate shielding gas. ✓

- Joint contamination. ✓

- Too low current. ✓

- Improper slag removal from previous weld. ✓

- Excessive weaving ✓

- Electrode at incorrect angle ✓

(Any 2 x 1) (2)

8.2 Factors determining gas pressure for oxy acetylene welding:

- The nozzle size.✓

- Thickness of material. ✓ (2)

8.3 Factors determining current setting for welding:

- Base metal type.✓

- Base metal thickness. ✓

- Electrode diameter. ✓

- Position of the weld. ✓

(Any 2 x 1)(2)

8.4 Preventative measures for weld defects:

8.4.1 Porosity:

- Cleaning the welding surface. ✓

- Use dry electrodes. ✓

- Avoid rust on electrode. ✓

- Ensure that supply of shielding gas is not interrupted. ✓

- Avoid welding in windy conditions. ✓

- Use correct arc length. ✓

(Any 2 x 1) (2)

8.4.2 Incomplete penetration:

- Set to correct current setting. ✓

- Apply the correct electrode angle. ✓

- Increase the travel speed.✓

- Use the correct root gap. ✓

- Ensure the correct joint preparation.✓

(Any 2 x 1) (2)

8.5 Guided bend test:

- Lack of fusion.✓

- Incomplete penetration. ✓

- Cracks in the weld metal.✓

- Quality of the weld at the face and root of the weld. ✓

(Any 2 x 1) (2)

8.6 Visual inspection process:

- Shape of profile. ✓

- Uniformity of the surface. ✓

- Overlap. ✓

- Undercutting. ✓

- Penetration bead. ✓

- Root groove. ✓

- Slag inclusion. ✓

- Spatter. ✓

- Cracks. ✓

(Any 3 x 1) (3)

8.7 X-ray test:

- The X-ray or gamma ray source is placed in front of the object being tested. ✓

- The film is put behind the object being tested. ✓

- The source is activated and the X-rays/gamma penetrate the test piece. ✓

- As they pass through the areas of lower density (air pockets, cracks or inclusions) ✓the rays expose the film as lighter on the negative, indicating a welding defect.✓

- Film or picture need to be analyzed. ✓ (6)

[23]

QUESTION 9: JOINING METHODS (Stresses and Distortion) (Specific)

9.1 Distortion:

Weld distortion is the warping of the base plate ✓ caused by heat from the welding arc/flame. ✓ (2)

9.2 Effect of cold working on steel:

- To break down the crystal structure elongating the grains. ✓

- It gives the metal greater hardness and tensile strength. ✓

- It reduces ductility. ✓

- Steel can be made to recrystallize under the action of heat. ✓ (4)

9.3 Factors that affect distortion and residual stress:

- If the expansion that occurs when metal is heated is resisted ✓then deformation will occur. ✓

- When contraction that occurs on cooling is resisted ✓ then a stress will be applied. ✓

- If this stress causes movement ✓then distortion occurs.✓

- If this stress does not cause movement ✓ then there will be residual stress in the welded joint. ✓

(Any 2 x 2) (4)

9.4 Rate of cooling:

- The size of the work piece. ✓

- Weld thickness. ✓

- Thermal conductive properties of parent metal. (Type of material) ✓ (3)

9.5 The iron-carbon equilibrium diagram:

- Ferrite and pearlite ✓

- Ferrite and austenite ✓

- Austenite ✓

- Cementite and austenite ✓

- Pearlite and cementite ✓ (5)

[18]

QUESTION 10: MAINTENANCE (Specific)

10.1 Lockout on machines:

To ensure that nobody can turn on the machine✓ while maintenance is being carried out.✓ (2)

10.2 Tagging plates:

It has multiple holes, so that more than one technician can lock out the machine simultaneously. ✓ (1)

10.3 Aspects of plant and equipment maintenance:

- Do not ignore maintenance. ✓

- Do not ignore reports of damaged or unsafe equipment. ✓

- Do not ignore faulty or damaged equipment. ✓

- Do not ignore inspection. ✓

(Any 2 x 1) (2)

10.4 Maintenance guidelines of the horizontal band saw:

- Check electrical wiring and isolation. ✓

- Change the band saw blade as required. ✓

- Check band wheels at every blade change. ✓

- Monitor band wheel bearings.✓

- Inspect band guides. ✓

- Inspect the condition of the guards. ✓

- Check blade tension and alignment. ✓

- Inspect the hydraulic system and oil level.✓

- Check vice for wear on both stationary and movable parts. ✓

- Align vice with the blade. ✓

- Inspect the chip removal system daily. ✓

(Any 2 x 1) (2)

10.5 Effect of overloading of the rolling machine:

It limits the lifespan ✓ of bearings, gearbox and motor components. ✓(2)

[09]

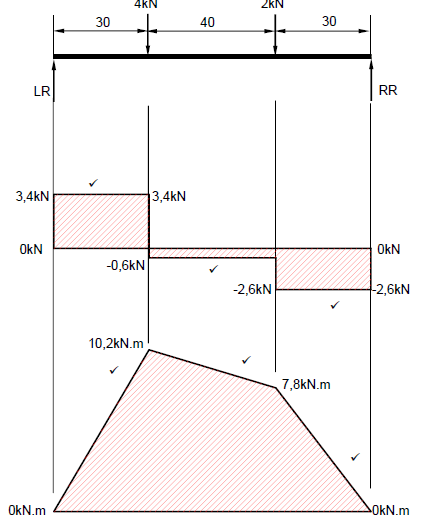

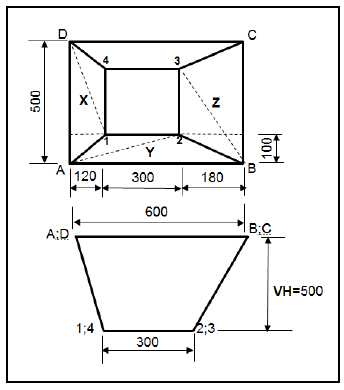

QUESTION 11: DEVELOPMENT (Specific)

11.1 Square to rectangular hopper off centre:

11.1.1 True lengths of A-1:

Vertical height = 500 mm

True length (A-1):

A - 1 = √1202 + 1002 + 5002

= √14400 + 10000 + 250000

= 523,83mm (4)

11.1.2 True length (A-2):

Vertical height = 500 mm

A - 2 = √1002 + 4202 + 5002

= √10000 + 176400 + 250000

= 660,61mm (4)

11.1.3 True length (B-2):

Vertical height = 500 mm

B - 2 = √1002 + 1802 + 5002

= √10000 + 32400 + 250000

= 540,74mm (4)

11.1.4 True length (B-3):

Vertical height = 500 mm

B - 3 = √1802 + 4002 + 5002

= √32400 + 160000 + 250000

= 665,13mm (4)

11.1.5 True length(D-1):

Vertical height = 500 mm

D - 1= √1202 4002 5002

= √14400 + 160000 + 250000

= 651,46mm (4)

[20]

TOTAL : [200]