MECHANICAL TECHNOLOGY: FITTING AND MACHINING GRADE 12 QUESTIONS - NSC PAST PAPERS AND MEMOS MAY/JUNE 2019

Share via Whatsapp Join our WhatsApp Group Join our Telegram GroupMECHANICAL TECHNOLOGY: FITTING AND MACHINING

GRADE 12

NATIONAL SENIOR CERTIFICATE EXAMINATIONS

MAY/JUNE 2019

INSTRUCTIONS AND INFORMATION

- Write your centre number and examination number in the spaces provided on the ANSWER BOOK.

- Read ALL the questions carefully.

- Answer ALL the questions.

- Number the answers correctly according to the numbering system used in this question paper.

- Start EACH question on a NEW page.

- Show ALL calculations and units. Round off final answers to TWO decimal places.

- Candidates may use non-programmable scientific calculators and drawing instruments.

- The value of gravitational acceleration should be taken as 10 m.s-2.

- All dimensions are in millimetres, unless stated otherwise in the question.

- Write neatly and legibly.

- A formula sheet is attached at the end of the question paper.

- Use the criteria below to assist you in managing your time.

| QUESTION | CONTENT | MARKS | TIME in minutes |

| GENERIC | |||

| 1 | Multiple-choice questions | 6 | 6 |

| 2 | Safety | 10 | 10 |

| 3 | Materials | 14 | 14 |

| SPECIFIC | |||

| 4 | Multiple-choice questions | 14 | 10 |

| 5 | Terminology (Templates) | 23 | 20 |

| 6 | Tools and Equipment | 18 | 15 |

| 7 | Forces | 45 | 30 |

| 8 | Joining Methods (Inspection of Weld) | 23 | 20 |

| 9 | Joining Methods (Stresses and Distortion) | 18 | 20 |

| 10 | Maintenance | 8 | 10 |

| 11 | Terminology (Developments) | 21 | 25 |

| TOTAL | 200 | 180 | |

QUESTION 1: MULTIPLE-CHOICE QUESTIONS (GENERIC)

Various options are provided as possible answers to the following questions. Choose the answer and write only the letter (A–D) next to the question numbers (1.1 to 1.6) in the ANSWER BOOK, e.g. 1.7 E.

1.1 Which Act is the code of good practice with regard to HIV/Aids and employment at the workplace?

- The Act on safety states that all employees must make sure that the workplace is safe and that employers are not at risk of becoming infected with HIV at work.

- The Act contains common guidelines on how employers, employees and trade unions should respond to HIV in the workplace.

- Employers may demote employees based on their HIV status (Act 33 of 2000).

- Employers can simply dismiss a person who has HIV (Act 34 of 2000). (1)

1.2 Which ONE of the following is a reason why oil and grease must NOT be allowed to come into contact with oxygen and acetylene fittings? It will …

- cause blockages.

- form a flammable mixture.

- make the oxygen fittings slippery.

- accumulate dust. (1)

1.3 Which ONE of the following is an advantage of the process workshop layout?

- There is high machine utilisation because more than one product is manufactured.

- Production is not always continuous.

- Transportation costs between process departments may be high.

- There may be damage to fragile goods as a result of extra handling. (1)

1.4 Which ONE of the following factors is important in the heat treatment of steel?

- Temperature

- Colour

- Length

- Shape (1)

1.5 What is the purpose of annealing steel?

- Harden it

- Temper it

- Harden the core

- Relieve internal stresses (1)

1.6 Which ONE of the following sounds will indicate cast iron when a sound test is carried out?

- Loud and clear sound

- Very dull sound

- High ringing sound

- High-frequency sound (1)

[6]

QUESTION 2: SAFETY (GENERIC)

2.1 A welded joint needs to be ground using an angle grinder. State TWO safety measures to be observed when using the angle grinder. (2)

2.2 Give TWO reasons why it is important to wear welding goggles during gas welding. (2)

2.3 Name TWO items of personal protective equipment (PPE) that one will use when working with a bench grinder. (2)

2.4 Explain the difference between the process workshop layout and the product workshop layout. (2)

2.5 Describe the employer's responsibility regarding equipment in the workplace. (2)

[10]

QUESTION 3: MATERIALS (GENERIC)

3.1 Name and describe the FOUR tests used to distinguish between the different types of materials. (8)

3.2 Give the reason why the following heat-treatment processes are performed on steel:

3.2.1 Tempering (2)

3.2.2 Normalising (2)

3.2.3 Hardening (2)

[14]

QUESTION 4: MULTIPLE-CHOICE QUESTIONS (SPECIFIC)

Various options are provided as possible answers to the following questions. Choose the answer and write only the letter (A–D) next to the question numbers (4.1 to 4.14) in the ANSWER BOOK, e.g. 4.15 E.

4.1 Which ONE of the following statements describes an advantage of the tailstock set-over method for taper turning on the centre lathe?

- One cannot use the automatic feed.

- Only internal tapers can be cut.

- Tapers with large angles can be cut.

- Good finishing is obtained. (1)

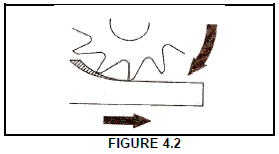

4.2 Identify the milling process shown in FIGURE 4.2 below.

- Down-cut milling

- Up-cut milling

- Slot milling

- Straddle milling (1)

4.3 Which ONE of the following indexing processes uses the universal dividing head to cut a surface at 16°30'?

- Differential indexing

- Angular indexing

- Rapid indexing

- Simple indexing (1)

4.4 What is meant by the term 'absolute programming' on a 3-axis digital read-out system? Point of reference being taken from …

- the previous point.

- the zero point.

- a common point.

- any point. (1)

4.5 If the addendum of a spur gear is 3 mm, what will be the module?

- 6

- 3

- 8

- 9 (1)

4.6 Which ONE of the following statements describes the function of the tensile tester?

- Illustrates the concept of stress-strain ratio of the triangle of forces.

- Determines the stress-strain ratio of a material.

- Illustrates the concept of the parallelogram of forces.

- Determines the compressive strength of a material. (1)

4.7 What is the measure unit for strain?

- Newton

- Pascal

- No unit

- Newton/metre (1)

4.8 What is the measure unit for moments?

- Nm

- Pa

- No unit

- N/m (1)

4.9 Which ONE of the following materials is classified as a thermo-hardened composite?

- Nylon

- Teflon

- Carbon fibre

- Vesconite (1)

4.10 What can be done to reduce the coefficient of friction between two surfaces?

- Increase the weight of the object

- Add lubrication between the surfaces

- Reduce lubrication between the surfaces

- Increase the perpendicular load on the surface (1)

4.11 Which ONE of the following refers to the helix angle of a screw thread? The angle that the thread makes with … of the screw thread.

- the pitch

- a line perpendicular to the axis

- the crest

- the root (1)

4.12 Unless stated otherwise, what clearance angle is normally used to calculate the leading and following tool angles of a square thread cutting tool?

- 90°

- 45°

- 5°

- 3° (1)

4.13 Which ONE of the following statements is an advantage of a belt drive system when compared with a gear drive system?

- Drive can take place over a long distance.

- Expensive parts are used.

- More power can be transmitted.

- Power transmission without slip is possible. (1)

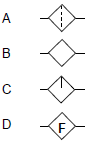

4.14 Which ONE of the following symbols is used to indicate a filter in a hydraulic flow diagram? (1)

(1)

[14]

QUESTION 5: TERMINOLOGY (LATHE AND MILLING MACHINE) (SPECIFIC)

5.1 Calculate the tailstock set-over required for turning a taper of 7° (included angle) on a centre lathe, if the taper is 320 mm long. (3)

5.2 Name THREE methods that can be used to cut multiple-start screw threads on a lathe. (3)

5.3 Calculate the following dimensions of a parallel key suitable for a 48 mm diameter shaft:

5.3.1 Width (2)

5.3.2 Thickness (2)

5.4 State TWO advantages of using the compound slide method rather than the cross-slide method to cut an external V-thread on the centre lathe. (2)

5.5 State ONE advantage of EACH of the following milling processes:

5.5.1 Down-cut milling (1)

5.5.2 Up-cut milling (1)

5.6 Use neatly labelled sketches to show the difference between gang milling and straddle milling. (4)

[18]

QUESTION 6: TERMINOLOGY (INDEXING) (SPECIFIC)

6.1 A spur gear has a pitch-circle diameter of 99 mm and a module of 3.

Calculate the following:

6.1.1 Number of teeth (2)

6.1.2 Outside diameter (2)

6.1.3 Cutting depth (2)

6.1.4 Addendum (1)

6.1.5 Dedendum (2)

6.1.6 Circular pitch (2)

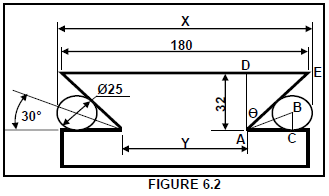

6.2 FIGURE 6.2 below shows a dovetail part. Calculate distances Y and X. (11)

6.3 A gear with 119 teeth must be cut on a universal milling machine with the help of a Cincinnati dividing head.

Determine the following by using differential indexing:

6.3.1 Indexing required (choose 120 teeth) (2)

6.3.2 Change gears required (3)

6.3.3 Direction of rotation of the index plate in terms of the index crank. (1)

[28]

QUESTION 7: TOOLS AND EQUIPMENT (SPECIFIC)

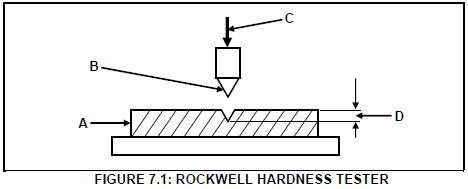

7.1 FIGURE 7.1 below shows the Rockwell hardness tester used to determine the hardness of a metal. Label A–D in FIGURE 7.1. (4)

7.2 What is the purpose of the moment tester? (2)

7.3 Describe the operation of the tensile tester. (4)

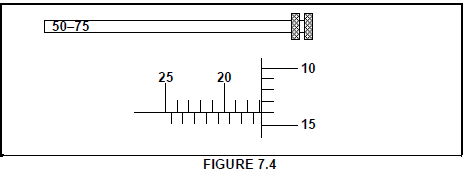

7.4 What is the reading on the depth micrometer as shown in FIGURE 7.4 below? (3)

(3)

[13]

QUESTION 8: FORCES (SPECIFIC)

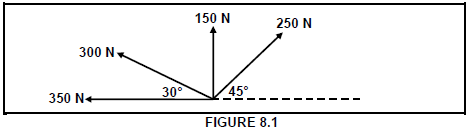

8.1 FIGURE 8.1 below shows a system of forces with four coplanar forces acting onto the same point. Use calculations and determine the magnitude and direction of the resultant force for this system of forces.

HINT: Draw and complete the diagram in FIGURE 8.1. Show ALL the horizontal and vertical components before you do the calculation. (13)

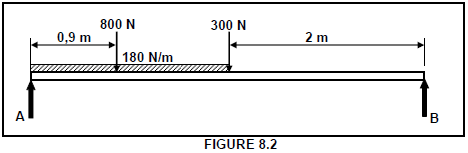

8.2 The diagram in FIGURE 8.2 below shows a 4 m long beam supported by two vertical supports, A and B. Two vertical point loads of 800 N, 300 N and a uniformly distributed load of 180 N/m is exerted over the left half of the beam. Calculate the magnitude of the reactions in supports A and B. (Draw and complete the diagram in FIGURE 8.2. Indicate the point load replacing the uniformly distributed load.) (8)

8.3 A load of 40 kN causes a tensile stress of 20 MPa in a solid brass shaft. The original length of the shaft is 2 m and Young's modulus of elasticity for brass is 90 GPa.

Determine the following with the help of calculations:

8.3.1 Diameter of the shaft (5)

8.3.2 Strain (4)

8.3.3 Change in length (3)

[33]

QUESTION 9: MAINTENANCE (SPECIFIC)

9.1 Give TWO reasons why preventative maintenance is important for mechanical drive systems. (2)

9.2 State TWO preventative maintenance procedures on gear drive systems. (2)

9.3 State TWO causes of the malfunctioning of belt drive systems. (2)

9.4 State TWO procedures that can be followed to reduce wear on a chain drive system. (2)

9.5 State TWO properties of EACH of the following materials:

9.5.1 Fibre glass (2)

9.5.2 Vesconite (2)

9.5.3 Carbon fibre (2)

9.6 Classify the following materials as thermoplastic composites or thermo-hardened (thermosetting) composites:

9.6.1 Teflon (1)

9.6.2 Bakelite (1)

9.6.3 Polyvinyl chloride (PVC) (1)

9.7 Which material, rubber or thermo composites, has the higher coefficient of friction? (1)

[18]

QUESTION 10: JOINING METHODS (SPECIFIC)

10.1 A three-start square thread with a lead of 30 mm needs to be cut on a lathe. The crest diameter of the thread is 75 mm and the clearance angle is 3°.

Calculate the following:

10.1.1 Pitch diameter (4)

10.1.2 Helix angle of the thread (4)

10.1.3 Leading tool angle (2)

10.1.4 Following tool angle (2)

10.2 A screw thread is identified as M16 x 2.

Give the meaning of EACH of the following:

10.2.1 M (1)

10.2.2 16 (1)

10.2.3 2 (1)

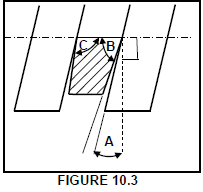

10.3 FIGURE 10.3 below shows a square cutting tool used to cut a left-hand square thread.

Identify the following angles:

10.3.1 A (1)

10.3.2 B (1)

10.3.3 C (1)

[18]

QUESTION 11: SYSTEMS AND CONTROL (DRIVE SYSTEMS) (SPECIFIC)

11.1 State TWO advantages of a chain drive system when compared with a belt drive system. (2)

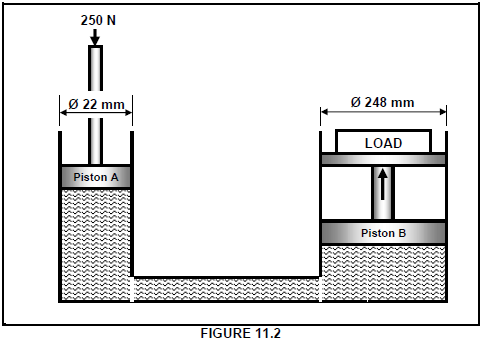

11.2 A hydraulic system is used to lift machine parts into position during the assembling process. The specifications of the system are diagrammatically presented in FIGURE 11.2 below.

Determine by means of calculations:

11.2.1 The fluid pressure in the hydraulic system if the system is in equilibrium (4)

11.2.2 The maximum load on piston B, if a force of 250 N is exerted onto piston A (6)

11.3 Describe the purpose of a filter in a hydraulic system. (2)

11.4 A V-belt is used in a belt drive system. The maximum force in the belt is 440 N and the ratio between the forces in the tight side and the slack side is 2,5. The belt speed is 10 m/s. Calculate the power transmitted. (5)

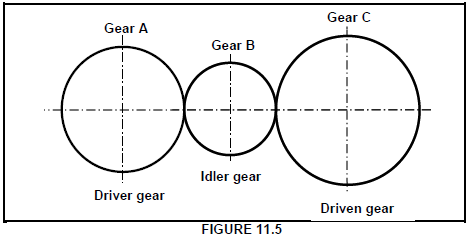

11.5 The gear system in FIGURE 11.5 below is used to control a garage door. The driven gear has 80 teeth and rotates at 260 r/min. The idler gear, used to change the direction, rotates at 800 r/min. The driver gear has 60 teeth.

Calculate:

11.5.1 The number of teeth on the idler gear (3)

11.5.2 The rotation frequency of the driver (3)

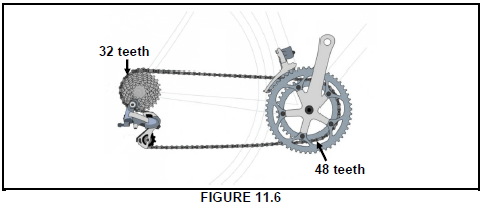

11.6 The chain drive system of a bicycle is shown in FIGURE 11.6 below. Calculate the gear ratio of the system. (3)

[28]

TOTAL: 200

FORMULA SHEET FOR MECHANICAL TECHNOLOGY (FITTING AND MACHINING)

- BELT DRIVES

Belt speed = πDN or v = πDN

60 60

Speed ratio= Diameter of driven pulley

Diameter of driver pulley

N1D1 = N2D2

Power (P) = 2πNT

60

Ratio of tight side to slack side = T1

T2

Power= (T1T2) π D N

60

where T force in the tight side

T2 = force in slack side

T1 - T2 = effective force (Te) - STRESS AND STRAIN

2.1 Stress = Force or σ = F

Area A

2.2 Strain (ε) = change in length (ΔL)

original length (L)

2.3 Young's modulus ( E ) = stress or ( σ )

strain ε

2.4 Ashaft = πd 2

4

2.5 Apipe =π(D2 - d2)

4

Safety factor = Break stress

Safe working stress - HYDRAULICS

Pressure (P) = Force (F) OR F1 = F2

Area (A) A1 A2

Volume = Cross-sectional area stroke length - KEYS AND KEYWAYS

Width of key = Diameter of shaft

4

Thickness of key = Diameter of shaft

6

Length of key = 1,5 Diameter of shaft

Standard taper for taper key 1 in 100 or 1:100 - GEAR DRIVES

Power (P) = 2πNT

60

N1T1 = N2T2

Gear ratio = Product of the number of teeth on driven gears

Product of the number of teeth on driving gears

Ninput = Product of the number of teeth on driven gears

Noutput Product of the number of teeth on driving gears

Torque = force x radius

Torque transmitted = gear ratio x input torque

Module ( m ) = Pitch -circle diameter (PCD)

Number of teeth ( T )

Pitch -circle diameter ( PCD ) = circular pitch ( CP ) number of teeth (T)

π

Outside diameter ( OD ) PCD 2 module

Addendum ( a ) module ( m )

Dedendum ( b ) 1,157 m or Dedendum ( b ) 1,25 m

Cutting depth ( h ) 2,157 m or Cutting depth ( h ) 2,25 m

Clearance ( c ) 0,157 m or Clearance ( c ) 0,25 m

Circular pitch ( CP ) m x π

Addc = m + Tm (1 - cos 90º)

2 T

tc= Tmsin 90º or tc= PCDsin 90º

T T - SCREW THREADS

Pitch diameter outside diameter - ½pitch

Pitch circumference π x pitch diameter

Lead = pitch x number of starts

Height of screw thread = 0,866 x p where p = pitch of the screw thread

Depth of screw thread = 0,613 x p where p = pitch of the screw thread

Number of turns = length

lead

Helix angle tan θ = lead

π x pitch diameter

Leading tool angle = 90º - (helix - clearance angle)

Following tool angle = 90 + (helix - clearance angle) - CINCINNATI DIVIDING HEAD TABLE FOR THE MILLING MACHINE

HOLE CIRCLES Side 1 24 25 28 30 34 37 38 39 41 42 43 Side 2 46 47 49 51 53 54 57 58 59 62 66 CHANGE GEARS 24 x 2 28 32 40 44 48 56 64 72 86 100 Simple indexing = 40 (where n Real number of divisions)

n

Angular indexing = n

9º

Change gears: Dr = (A - n ) x 40 or Dr = (A - n ) x 40

Dn A Dn A 1

(where A chosen divisions) (wheren Real number of divisions)