MECHANICAL TECHNOLOGY: FITTING AND MACHINING GRADE 12 MEMORANDUM - NSC EXAMS PAST PAPERS AND MEMOS NOVEMBER 2018

Share via Whatsapp Join our WhatsApp Group Join our Telegram GroupMECHANICAL TECHNOLOGY: FITTING AND MACHINING

GRADE 12

NSC EXAMS

PAST PAPERS AND MEMOS NOVEMBER 2018

MEMORANDUM

QUESTION 1: MULTIPLE-CHOICE QUESTIONS (GENERIC)

1.1 A ✔ (1)

1.2 C ✔ (1)

1.3 A ✔ (1)

1.4 B ✔ (1)

1.5 D ✔ (1)

1.6 A ✔ (1)

TOTAL QUESTION 1: [6]

QUESTION 2: SAFETY (GENERIC)

2.1 Angle grinder: (Before using)

- The safety guard must be in place before starting. ✔

- Protective shields must be placed around the object being grinded to protect the people around. ✔

- Use the correct grinding disc for the job. ✔

- Make sure that there are no cracks in the disc before you start. ✔

- Protective clothing and eye protection are essential. ✔

- Check electrical outlets and cord/plugs for any damages. ✔

- Ensure that lockable switch is disengaged. ✔

- Ensure that the disc and the nut are well secured. ✔

- Ensure that the removable handle is secured. ✔

- (Any 2 x 1) (2)

2.2 Welding goggles:

- To protect your eyes against sparks ✔

- To protect your eyes against heat ✔

- To be able to see where to weld ✔

- To protect your eyes from UV rays ✔

- (Any 2 x 1) (2)

2.3 PPE for Hydraulic Press:

- Overall ✔

- Safety shoes / boots✔

- Safety goggle ✔

- Leather gloves ✔

- Face shield ✔

- (Any 2 x 1) (2)

2.4 Workshop layouts:

- Process layout ✔

- Product layout ✔ (2)

2.5 Employer’s responsibility regarding first-aid:

- Provision of first-aid equipment ✔

- First aid training ✔

- First-aid services by qualified personnel ✔

- Any first aid procedures / treatment ✔

- Display first aid safety signs ✔

- First aid personnel must be identified by means of arm bands or relevant personal signage ✔

- (Any 2 x 1) (2)

TOTAL QUESTION 2: [10]

QUESTION 3: MATERIALS (GENERIC)

3.1 Bending test:

- Ductility ✔✔

- Malleability ✔✔

- Brittleness ✔✔

- Flexibility ✔✔

- (Any 1 x 2) (2)

3.2 Heat-treatment:

3.2.1 Annealing:

- To relieve internal stresses ✔

- To soften the steel ✔

- To make the steel ductile ✔

- To refine the grain structure of the steel ✔

- To reduce the brittleness of the steel ✔

- (Any 2 x 1) (2)

3.2.2 Case hardening:

- To require a wear resistant surface ✔ and it must be tough enough internally ✔ at the core to withstand the applied loads.

- Hard case ✔ and tough core. ✔

- (Any 1 x 2) (2)

3.3 Tempering process:

- To reduce ✔ the brittleness ✔ caused by the hardening process.

- Relieve ✔ strain ✔ caused during hardening process.

- Increase ✔ the toughness of the steel. ✔

- (Any 1 x 2) (2)

3.4 Factors for heat-treatment processes:

- Heating temperature / Carbon content ✔

- Soaking (Time period at temperature) / Size of the work piece ✔

- Cooling rate / Quenching rate ✔ (3)

3.5 Hardening of steel:

- Steel is heated to 30 – 50°C above the higher critical temperature. (AC3) ✔

- It is then kept at that temperature to ensure (soaking) that the whole structure is Austenite. ✔

- The steel is then rapidly cooled by quenching it in clean water, brine or oil. ✔ (3)

TOTAL QUESTION 3: [14]

QUESTION 4: MULTIPLE-CHOICE QUESTIONS (SPECIFIC)

4.1 C ✔ (1)

4.2 A ✔ (1)

4.3 D ✔ (1)

4.4 A ✔ (1)

4.5 B ✔ (1)

4.6 A ✔ (1)

4.7 B ✔ (1)

4.8 B ✔ (1)

4.9 D ✔ (1)

4.10 C ✔ (1)

4.11 B ✔ (1)

4.12 D ✔ (1)

4.13 D ✔ (1)

4.14 C ✔ (1)

TOTAL QUESTION 4: [14]

QUESTION 5: TERMINOLOGY (LATHE AND MILLING MACHINE) (SPECIFIC)

5.1 Advantages of using the tailstock to cut an external taper:

- Long an accurate taper can be cut. ✔

- The automatic feed can be used which result in a good finish. ✔ (2)

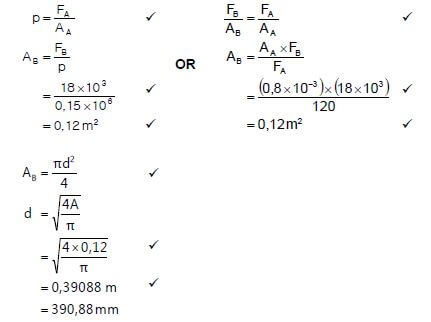

5.2 Calculate the compound slide set-over:

- Tan θ = D - d

2 2L

Tan θ = 60 - 28

2 2 × 85

= 0,188 ✔ ✔

θ = 10,66 º

2

OR

- X = D - d

2

= 60 - 28

2

= 16 mm - Tan θ = 16

2 85

θ = 10,66 º (5)

2

5.3 Centre gauge:

- To measure the form and angle of the screw cutting tool angle while grinding the tool ✔

- To set the screw cutting tool square/perpendicular to the axis of the work piece ✔ (2)

5.4 Parallel key:

Length:

- Length = 1,5 × diameter

= 1,5 × 42 ✔ ✔

= 63 mm ✔ (3)

5.5 Advantages of up-cut milling:

- Deeper cuts can be made as the cutting pressure on the cutter is lower than down cut milling. ✔

- The process enables hard steel to be cut, because the total cutting pressure is absorbed by the material at the back of the edge. ✔

- Metal with hard scale, such as castings or forgings, the cut is started under the scale where the material is softer which extends the life of the cutter. ✔

- A quicker/course feed can be used. ✔

- The strain on the cutter and arbour will be less. ✔

- Vibration is limited ✔

- Good finish ✔

- Low noise level ✔

- (Any 2 x 1) (2)

5.6 Disadvantage of down-cut milling:

- Vibration in the arbour is unavoidable. ✔

- A fine feed must be used. ✔

- When milling a material with hard scale the milling cutter will be damaged. ✔

- Process takes time because of slower feed. ✔

- Noisy process. ✔

- Bad finish because of vibration. ✔

- (Any 2 x 1) (2)

5.7 Methods of centring a milling cutter:

- Square and ruler method. ✔

- Set-over method by milling machine dial. ✔

- Dial indicator method ✔

- Using reference points on digital read out equipment ✔

- (Any 2 x 1) (2)

TOTAL QUESTION 5: [18]

QUESTION 6: TERMINOLOGY (INDEXING) (SPECIFIC)

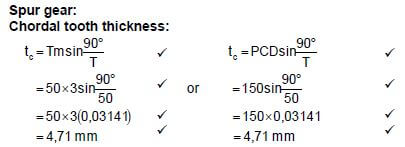

6.1 Spur gear:

Chordal tooth thickness:  (4)

(4)

6.2 Calculate simple indexing:

- Simple Indexing = 40

N

= 40

13

= 3 1

13

= 3 1 × 3

13 3 - = 3 3

39

3 full turns and 3 holes in a 39 hole circle (4)

6.3 Differential indexing:

6.3.1 Indexing required:

- Indexing = 40 = 40

n 127

= 40 = 40 ÷ 5

A 125 5

= 8

25

Indexing 8 holes on the 25 hole circle (3)

6.3.2 Change gears required:

- Dr = A-n × 40

Dn A 1

= 125 - 127 × 40

125 1

= 2 × 40

125 1

= -80 ÷ 5

125 5

= -16 × 4

25 4

= -64

100 (5)

6.3.3 Direction of rotation of index plate:

- The index plate will turn the opposite ✔ direction as the index crank handle. (1)

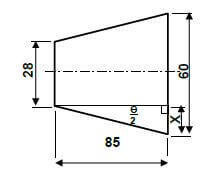

6.4 Calculate distance “x” between rollers:

- "x"=150 +2(AB)− 2(CD)− 2r

tanθ = BC

AB

AB = BC

tanθ

= 35

tan 60º

= 20,207 mm

= 20,21 mm - tanθ = DE

CD

CD = 15

tanθ

CD = 15

tan30º

= 25,98 mm

- " x" = 150 + 2(AB) - 2(CD) - 2r

= 150 + 2 (20,21) - 2 (25,98) - 2 (15)

= 150 + 40,42 - 51,96 - 30

= 108,454m m

= 108,45 m m ✔ (9)

6.5 Reasons for balancing work piece on a centre lathe:

- Prevent unnecessary bearing loads ✔

- Prevent excessive vibration ✔

- To obtain a good finish ✔

- To prevent clatter on the gear teeth ✔

- To prevent the spindle from bending ✔

- (Any 2 x 1) (2)

TOTAL QUESTION 6: [28]

QUESTION 7: TOOLS AND EQUIPMENT (SPECIFIC)

7.1 Hardness testers:

- Brinell-hardness tester ✔

- Rockwell-hardness tester ✔

- Vickers ✔

- (Any 2 x 1) (2)

7.2 Moment tester:

- To determine the reactions ✔ on either side of a simply loaded beam. ✔ (2)

7.3 Tensile test:

- A piece of material is subjected to an increasing axial load ✔ while measuring ✔ the corresponding elongation ✔ of the material. (3)

7.4 Depth micro-meter:

- Reading = 100 + 11,00 + 0,50 + 0,09 ✔

= 111,59 mm (5)

7.5 Measure depth:

- Vernier calliper ✔ (1)

TOTAL QUESTION 7: [13]

QUESTION 8: FORCES (SPECIFIC)

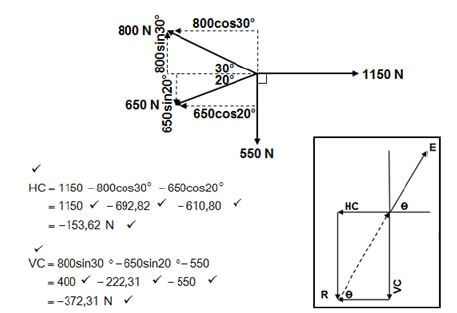

8.1 Forces:  (15)

(15)

Horizontal Components | Magnitudes | Vertical Components | Magnitudes |

1150cos0° | 1150N | 1150sin0° | 0N |

800cos150° | -692,82N | 800sin150° | 400N |

650cos200° | -610,80N | 650sin200° | -222,31N |

550cos270° | 0N | 550sin270° | -550N |

TOTAL: | -153,62N | TOTAL: | -372,31N |

- E2 = HC2 + VC2

√E2 = √(53,62 + 372,312)

E = 402,76N

Tanθ = VC

HC

= 372.31

153,62

θ = 67,58º

Equilibrant = 402,76N en 67,58º North from East (15)

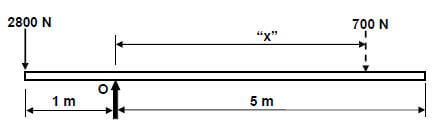

8.2 Moments:

Calculate “x”:

Take moments about O.

- ∑RHM = ∑LHM

700 × "x" 2800 × 1

700 × "x" 2800

"×" = 2800

700

"x" = 4m ✔ ✔ (4)

8.3 Stress and Strain:

8.3.1 Type of stress:

- Compressive stress ✔ (1)

8.3.2 Stress:

- A = π(D2 -d2)

4

= π(0,042 - 0,032)

4

= A = 0,55 × 10σ m2

σ = F

A

= 50 × 10σ

0,55 ×10σ

σ = 90,91 × 10σ Pa

σ = 90,91 MPa ✔

(NO UNIT – NO MARK) (5)

8.3.3 Change in length:

- E = σ

ε

ε = σ

E

= 90,91 × 106 ✔

90 × 109

= 1,01 × 10-3 ✔

(IF ANY UNIT IS GIVEN – NO MARK)

- ε = ΔL

L

ΔL = ε × L

= (1,01 × 10-3) × 80

= 0,08 mm ✔ (5)

8.3.4 Safety factor:

- Safety factor = Break stress

Safe workingstress

Safe workingstress = Break stress

Safety factor

= 600 × 106

4

= 150 × 106 Pa

= 150 MPa ✔(3)

TOTAL QUESTION 8: [33]

QUESTION 9: MAINTENANCE (SPECIFIC)

9.1 Lack of preventative maintenance:

- Risk of injury or death. ✔

- Financial loss due to damage suffered as a result of part failure and the waste of material. ✔

- Loss of valuable production time. ✔ (3)

9.2 Causes for the malfunctioning of chain drive systems:

- Lack of or incorrect lubrication ✔

- Lack of maintenance ✔

- Overloading ✔

- Misalignment of sprockets ✔

- Incorrect chain tension ✔

- Contamination of chain drive system such as dust or sand ✔

- (Any 2 x 1) (2)

9.3 Procedures to reduce the physical wear on a belt drive system:

- Check the belt alignment. ✔

- Checking the belt tension. ✔

- Prevent overloading of the system. ✔

- Keep the pulleys and belt clean. ✔

- Check that all covers are secure. ✔

- (Any 2 x 1) (2)

9.4 Procedures to replace the belt on a belt drive system:

- Ensure that the machine is switched off ✔

- Release the tension on the belt ✔

- Remove the belt from the pulleys ✔

- Fit the correct size replacement belt onto the pulleys ✔

- Check the pulley alignment ✔

- Apply adequate tension according to specification and lock the system ✔

- (Any 5 x 1) (5)

9.5 Properties of materials:

9.5.1 Poly vinyl chloride (PVC):

- Flexible ✔

- Rubber-like substance ✔

- Makes a dull sound when dropped ✔

- Tough ✔

- Act as an insulator ✔

- It is durable ✔

- Highly resistant to oxidative material ✔

- Oil, water and chemical resistant ✔

- (Any 1 x 1) (1)

9.5.2 Carbon fibre:

- Strong ✔

- Tough ✔

- Light weight ✔

- Good electrical conductor ✔

- (Any 1 x 1) (1)

9.6 Difference between “Thermoplastic” and “Thermo hardened (thermosetting)” composites:

- Thermoplastics can be reheated and deformed. / Recyclable ✔

- Thermo hardened cannot be reheated. / Non-recyclable ✔ (2)

9.7 Examples of thermo hardened composites:

- Carbon fibre or (Any application) ✔

- Glass fibre or (Any application) ✔

- Bakelite or (Any application) ✔

- Teflon or (Any application) ✔

- (Any 2 x 1) (2)

TOTAL QUESTION 9: [18]

QUESTION 10: JOINING METHODS (SPECIFIC)

10.1 Square thread:

10.1.1 The lead of the thread:

- Lead = pitch × no of starts

= 5 × 2 ✔

= 10 mm ✔ (2)

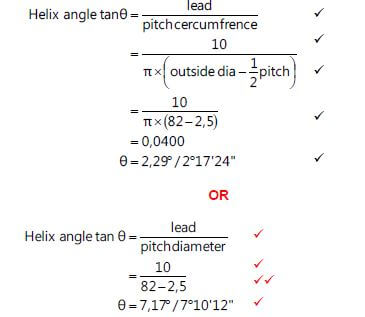

10.1.2 The helix angle of the thread:  (5)

(5)

10.1.3 The leading tool angle:

- Leadingtoolangle 90º helix angle + clearanceangle

= 90º - (2,29º + 3º)

= 84,71º /84º 42'36"

OR - Leadingtoolangle 90º helix angle + clearanceangle

= 90º - (7,17º + 3º)

79,83º / 79º 49'48" (2)

10.1.4 The following tool angle:

- Followingtoolangle = 90º + (helix angle - clearanceangle)

= 90º + (2,29º - 3º)

= 89,29º /89º 17'24"

OR - Following toolangle = 90º + (helix angle - clearanceangle)

= 90º + ( 7,17º - 3º)

= 94,17º / 94º 10'12" (2)

10.2 Measurements of a screw thread :

10.2.1 Metric screw thread ✔ (1)

10.2.2 Crest / Major / External / Basic / Nominal / Outside diameter ✔ (1)

10.2.3 Pitch ✔ (1)

10.3 Angles of a square thread cutting tool:

- A – Helix angle ✔

- B – Clearance angle ✔

- C – Leading tool angle ✔

- D – Following tool angle ✔ (4)

TOTAL QUESTION 10: [18]

QUESTION 11: SYSTEMS AND CONTROL (DRIVE SYSTEMS) (SPECIFIC)

11.1 Advantages of a belt drive system compared to a chain drive system:

- Silent operation ✔

- Less expensive ✔

- Drive can take place over a longer distance ✔

- No lubrication needed ✔

- (Any 2 x 1) (2)

11.2 Hydraulics:

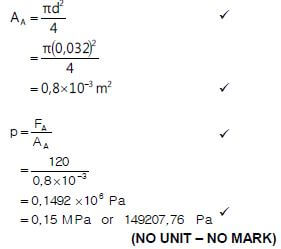

11.2.1 Fluid pressure:  (4)

(4)

11.2.2 Diameter of the ram:  (6)

(6)

11.3 Hydraulic symbols: One-way valve  (1)

(1)

11.4 Belt drives:

Rotation frequency of the drive pulley:

- NDRDDR = NDNDDN

NDR = NDN × DDN

DDR

= 80 × 240

75

= 256 r/min ✔ ✔ ✔ (4)

11.5 Gear drives:

11.5.1 Rotation frequency of the output:

- NA = Product of Driven gears

ND Product of Driver gears

ND = TA × TC

NA TB × TD

ND = TA × TC × NA

TB × TD

= 20 × 25 × 3000

35 × 30

ND = 1428,57 r/min

60

= 23,81 r/sec ✔

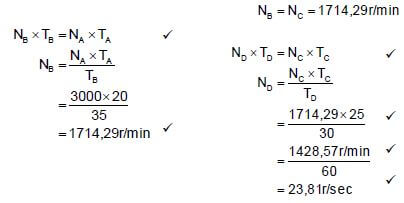

OR  (6)

(6)

11.5.2 Gear ratio:

- Gear ratio = Product of the number of teeth on driven gears✔

Product of the number of teeth on driver gears

=35 × 30

20 25

= 2,1 : 1 (3)

11.6 Work done:

- Work done F × s

= 250 × 15

= 3750 Jouleor N.m ✔(2)

TOTAL QUESTION 11: [28]

TOTAL: 200

(6)

(6)