MECHANICAL TECHNOLOGY GRADE 12 QUESTIONS - AMENDED SENIOR CERTIFICATE EXAMS PAST PAPERS AND MEMOS MAY/JUNE 2018

Share via Whatsapp Join our WhatsApp Group Join our Telegram GroupMECHANICAL TECHNOLOGY

GRADE 12

AMENDED SENIOR CERTIFICATE EXAMS

PAST PAPERS AND MEMOS

MAY/JUNE 2018

INSTRUCTIONS AND INFORMATION

- This question paper consists of TEN questions.

- Write your centre number and examination number in the spaces provided on the ANSWER BOOK.

- Read ALL the questions carefully.

- Answer ALL the questions.

- Number the answers correctly according to the numbering system used in this question paper.

- Start EACH question on a NEW page.

- Show ALL calculations and units. Round off ALL answers to TWO decimal places.

- Candidates may use non-programmable, scientific calculators and drawing instruments.

- Take the value of gravitational force as 10 m/s-2.

- All dimensions are in millimetres, unless stated otherwise in the question.

- A formula sheet for your use is attached to this question paper.

- Write neatly and legibly.

- Use the guidelines below to assist you in managing your time.

QUESTION | CONTENT | MARKS | TIME (minutes) |

1 | Multiple-choice questions | 20 | 15 |

2 | Safety | 10 | 10 |

3 | Tools and Equipment | 12 | 10 |

4 | Materials | 13 | 10 |

5 | Terminology | 30 | 20 |

6 | Joining Methods | 25 | 25 |

7 | Forces | 30 | 30 |

8 | Maintenance | 15 | 15 |

9 | Systems and Control | 25 | 25 |

10 | Turbines | 20 | 20 |

TOTAL | 200 | 180 | |

QUESTIONS

QUESTION 1: MULTIPLE-CHOICE QUESTIONS

Various options are provided as possible answers to the following questions. Choose the answer and write only the letter (A–D) next to the question number (1.1–1.20) in the ANSWER BOOK, for example 1.21 D.

1.1 What safety measure is applicable to the helical spring tester in terms of the Occupational Health and Safety Act, 1993 (Act 85 of 1993)?

- Make sure the spring is firmly in position.

- Use a hammer to remove the spring from the tester.

- Make sure that all contact surfaces between the compressor and the spring are well lubricated.

- Use wire to secure the spring in the tester. (1)

1.2 Which ONE of the following safety procedures applies to the gas analyser?

- Use water to remove dust from the exhaust system.

- Clean the gas inlet area with compressed air.

- Do not exceed the prescribed pressure in the tester.

- The work place must be well ventilated. (1)

1.3 Which ONE of the following equipment is used to test the compression in the cylinders of an internal combustion engine?

- Torsion tester

- Pressure tester

- Tensile tester

- Brinell tester (1)

1.4 Which property of material is determined with a Rockwell tester?

- Hardness

- Elasticity

- Tensile strength

- Brittleness (1)

1.5 What will be the result when steel is heated past the AC3 line?

- The grain structure will be at its finest.

- Steel will become brittle.

- It will start to lose magnetism.

- Steel will become a stronger magnet. (1)

1.6 Which ONE of the following is a property of ferrite?

- Brittle

- Soft

- Non-magnetic

- Hard (1)

1.7 What is the lead of a single-start metric V-screw thread with a pitch of 1,75 mm?

- 5,25 mm

- 3,5 mm

- 0,875 mm

- 1,75 mm (1)

1.8 What is a disadvantage of down-cut milling?

- The cutter blunts more rapidly.

- It cannot cut through thin pipes and tubes.

- A poor finish is produced.

- The coolant is not carried down to the teeth where it is required. (1)

1.9 How are welding defects observed when an X-ray test is performed on a welding joint? Welding defects are …

- visible on the weld.

- visible on film.

- determined by sound.

- visible on an oscilloscope screen. (1)

1.10 What is the purpose of applying a free-bend test on a welded joint?

- To detect internal defects

- To determine the hardness of the weld metal

- To detect external surface defects

- To determine the ductility of the weld metal (1)

1.11 What do you understand by the term stress in materials?

- External resistance in the material against an internal load

- External force in a material resisting an internal load

- Internal load caused by an external load

- Internal resistance in the material against an external load (1)

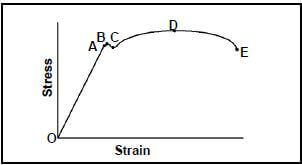

1.12 What does point D represents on the graph in FIGURE 1.12 below regarding the stress and strain?

FIGURE 1.12

- The proportionality between the stress and strain

- The maximum stress in the material

- The minimum stress in the material

- The difference between the stress and strain (1)

1.13 What is understood by 1 Pascal stress in material?

- 1 Pascal is the moments caused by a force of 1 Newton onto an area of 1 m2.

- 1 Pascal is the energy used by a force of 1 Newton over a distance of 1 meter.

- 1 Pascal is the amount of stress caused by a force of 1 Newton onto an area of 1 m2.

- 1 Pascal is the amount of work done by a force of 1 Newton onto an area of 1 m2. (1)

1.14 SAE 80 oil is used for …

- gearbox lubrication.

- engine lubrication.

- automatic transmission lubrication.

- power steering lubrication. (1)

1.15 The definition of the viscosity index of oil is a measure of how much the oil's viscosity changes as the ... changes.

- temperature

- pressure

- flow

- resistance (1)

1.16 Which ONE of the following statements defines Boyle's law? An ideal gas law where, at …

- constant pressure, the volume of an ideal gas is inversely proportional to its absolute temperature.

- constant volume, the temperature of an ideal gas is inversely proportional to its absolute pressure.

- constant temperature, the volume of an ideal gas is inversely proportional to its absolute pressure.

- constant temperature, the volume of an ideal gas is proportional to its absolute pressure. (1)

1.17 What will the velocity ratio of a belt drive system be if the driven pulley rotates at 1 000 r/min and the driver pulley at 500 r/min?

- 1 : 5

- 5 : 1

- 1 : 2

- 2 : 1 (1)

1.18 Which ONE of the following is a disadvantage of a flat belt drive system compared to a gear drive system?

- Flat belts can be used over long distances.

- The length of flat belts can be shortened.

- Flat belts can be rejoined after it snapped.

- Flat belts needs to be cleaned regularly. (1)

1.19 Which method is used to drive a turbocharger?

- Chain drive

- Belt drive

- Exhaust gasses

- Gear drive (1)

1.20 Identify the type of turbine in FIGURE 1.20 below regarding the principle of operation.

FIGURE 1.20

- Reaction turbine

- Extracting turbine

- Impulse turbine

- Induction turbine (1) [20]

QUESTION 2: SAFETY

2.1 Name any TWO pieces of personal safety equipment that you need to wear when working with an angle grinder. (2)

2.2 State THREE safety precautions you should observe before pressing a bearing from a shaft on a hydraulic press. (3)

2.3 Why is it important to wear an arc-welding helmet/shield during arc welding? (1)

2.4 State TWO safety precautions that should be adhered to before you start working on a milling machine. (2)

2.5 What safety aspect must be executed before leaving ANY machine after completing a given task? (1)

2.6 State ONE safety precaution you should observe when using a spring compressor to remove a coil spring from a motor vehicle's suspension. (1) [10]

QUESTION 3: TOOLS AND EQUIPMENT

3.1 Tools and equipment are very important to complete different tasks in the workplace. Explain the function of EACH of the following testing equipment:

3.1.1 Fuel pressure tester (2)

3.1.2 Torsion tester (2)

3.1.3 Cylinder leakage tester (2)

3.2 Give TWO reasons why it is necessary to perform a cylinder leakage test on an engine. (2)

3.3 Most welding companies use MIG/MAGS welding equipment for their welding.

3.3.1 State TWO advantages of the use of the MIG/MAGS welding process rather than the conventional arc welding process. (2)

3.3.2 Name TWO gasses used as inert gas in the MIGS/MAGS welding process. (2) [12]

QUESTION 4: MATERIALS

4.1 Define the term higher critical temperature in the heating of steel. (2)

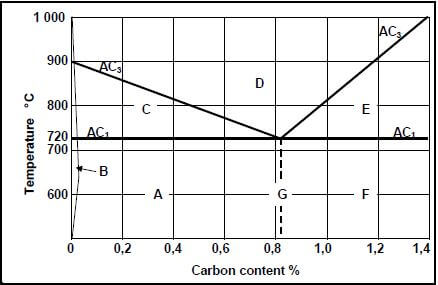

4.2 FIGURE 4.2 below shows a diagram. Answer the questions that follow.

FIGURE 4.2

4.2.1 Identify the diagram shown in FIGURE 4.2 above. (2)

4.2.2 Label structures A to G. (7)

4.2.3 To what temperature should steel, with a carbon content of 1,2%, be heated for hardening? (2) [13]

QUESTION 5: TERMINOLOGY

5.1 A parallel key must be machined to fit onto a 84 mm diameter shaft. Calculate the following:

5.1.1 The width of the key (2)

5.1.2 The thickness of the key (2)

5.1.3 The length of the key (2)

5.2 A spur gear with 106 teeth must be cut on a milling machine. Calculate the simple indexing needed to cut this gear with the help of a Cincinnati dividing head. (3)

5.3 The pitch of a metric V-screw thread is 2 mm. Calculate the depth of the screw thread. (HINT: H = 0,866 P) (2)

5.4 A spur gear has 48 teeth and a module of 3. Calculate the following:

5.4.1 Addendum (1)

5.4.2 Dedendum (2)

5.4.3 Clearance (2)

5.4.4 Pitch-circle diameter (PCD) (2)

5.4.5 Outside diameter (2)

5.4.6 Cutting depth (2)

5.4.7 Circular pitch (2)

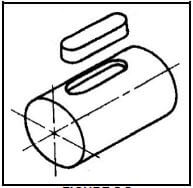

5.5 Identify the type of key shown in FIGURE 5.5 below.

FIGURE 5.5 (2)

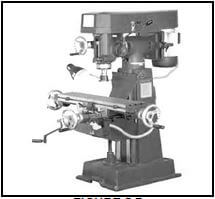

5.6 Identify the milling process shown in FIGURE 5.6 below.

FIGURE 5.6 (2) 5.7 Identify the engineering equipment shown in FIGURE 5.7 below.

FIGURE 5.7 (2) [30]

QUESTION 6: JOINING METHODS

6.1 State ONE cause of EACH of the following welding defects:

6.1.1 Porosity (1)

6.1.2 Undercutting (1)

6.1.3 Slag inclusion (1)

6.2 Name THREE destructive tests that can be executed onto a welded joint. (3)

6.3 Describe how the dye penetration test is done on a welded joint. (6)

6.4 What is the purpose of the inert gas used during the MIG/MAGS welding process? (3)

6.5 State THREE factors that should be considered during the MIG/MAGS welding process. (3)

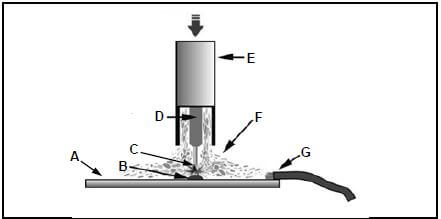

6.6 FIGURE 6.6 below shows the MIG/MAGS welding process. Label A to G. E

FIGURE 6.6 (7) [25]

QUESTION 7: FORCES

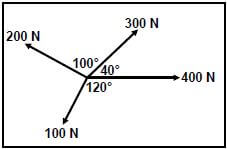

7.1 Four forces of are acting on the same point, as shown in FIGURE 7.1 below. Determine, by means of calculations, the magnitude and direction of the resultant of the system of forces in FIGURE 7.1.

FIGURE 7.1 (13)

7.2 A load of 80 kN is exerted onto a brass bush with an outer diameter of 62 mm and an inner diameter of 50 mm. The original length of the bush is 100 mm. Young's modulus for brass is 90 GPa.

Calculate the:

7.2.1 Stress in the bar (5)

7.2.2 Strain (3)

7.2.3 Change in length (3)

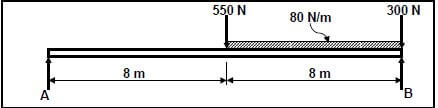

7.3 FIGURE 7.3 below shows a uniform beam that is supported by two vertical supports, A and B. A uniformly distributed force of 80 N/m is exerted over the right half of the beam. Determine, by means of calculations, the magnitudes of the reactions in supports A and B.

FIGURE 7.3 (6) [30]

QUESTION 8: MAINTENANCE

8.1 Why is it important to use oil with a higher viscosity in a manual transmission? (2)

8.2 Give the reason for using SAE20W50 oil in an internal combustion engine. (2)

8.3 Define the term pour point of a lubricant. (1)

8.4 State TWO properties of grease. (2)

8.5 State THREE maintenance measures for cutting fluid in a centre lathe or milling machine. (3)

8.6 Explain the effect when the viscosity of the oil used in an internal combustion engine is too low. (2)

8.7 Explain the reason for skimming the flywheel before installing a new clutch plate. (3) [15]

QUESTION 9: SYSTEMS AND CONTROL

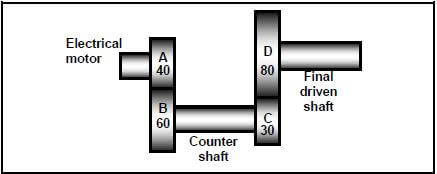

9.1 FIGURE 9.1 below shows a gear drive system. Driver gear A on the shaft of the electric motor has 40 teeth that mesh with gear B with 60 teeth on a counter shaft. On the counter shaft is another driver gear, C, with 30 teeth that mesh with gear D with 80 teeth on the final driven shaft.

FIGURE 9.1

Calculate the:

9.1.1 Rotation frequency of the final driven shaft if the electrical motor rotates at 1 440 r/min (3)

9.1.2 Velocity ratio between the input and output shafts (2)

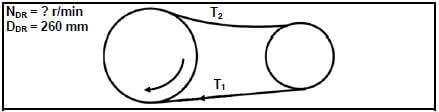

9.2 FIGURE 9.2 below shows a belt drive system with a 260 mm driver pulley. The belt speed of the system is 40 m.s-1. The tensile force in the slack side is 140 N and the ratio between the force in the tight side and the force in the slack side is 2,5.

FIGURE 9.2

Calculate the:

9.2.1 Rotation frequency of the driver pulley in r/min (revolutions per minute) (3)

9.2.2 Power transmitted (5)

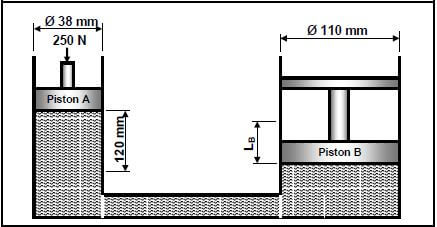

9.3 A hydraulic system is used to lift a machine. The specifications of the system are presented diagrammatically in FIGURE 9.3 below.

FIGURE 9.3

Calculate the:

9.3.1 Fluid pressure in the hydraulic system when in equilibrium (4)

9.3.2 Distance LB that Piston B will move with TEN strokes of Piston A (4)

9.4 State ONE advantage of the antilock braking system (ABS) in a motor vehicle compared to a system without ABS? (2)

9.5 Explain why the airbag safety system in a motor vehicle is referred to as an active safety feature. (2) [25]

QUESTION 10: TURBINES

10.1 Name TWO types of reaction turbines. (2)

10.2 Explain the operation of the impulse turbine. (6)

10.3 Why is it important to control the speed of a steam turbine? (2)

10.4 State THREE advantages of a gas turbine. (3)

10.5 What is the purpose of the waste gate in a turbocharger? (2)

10.6 What effect does a high altitude have on the performance of the engine of a motor vehicle? (2)

10.7 State ONE advantage of a turbocharger when compared to a supercharger. (1)

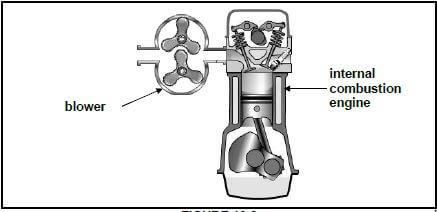

10.8 Identify the type of blower in FIGURE 10.8 used as a supercharger on an internal combustion engine.

FIGURE 10.8 (2)

[20]

TOTAL: 200

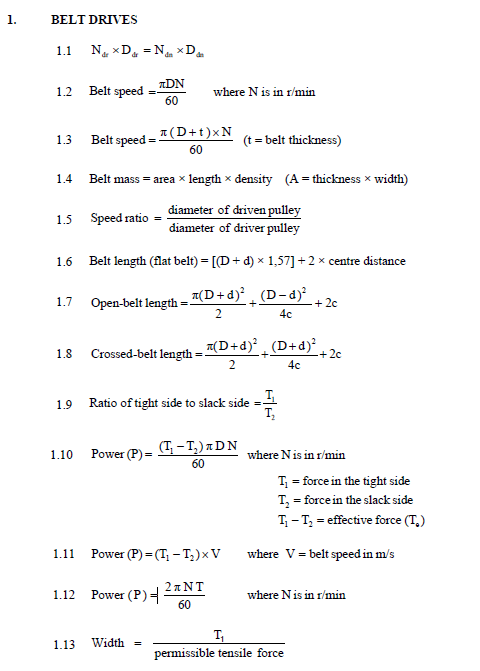

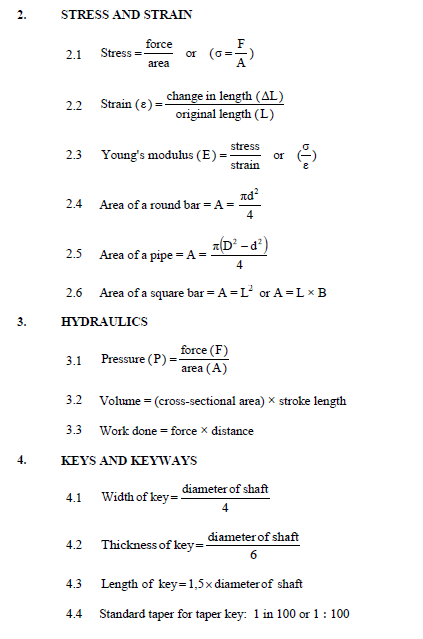

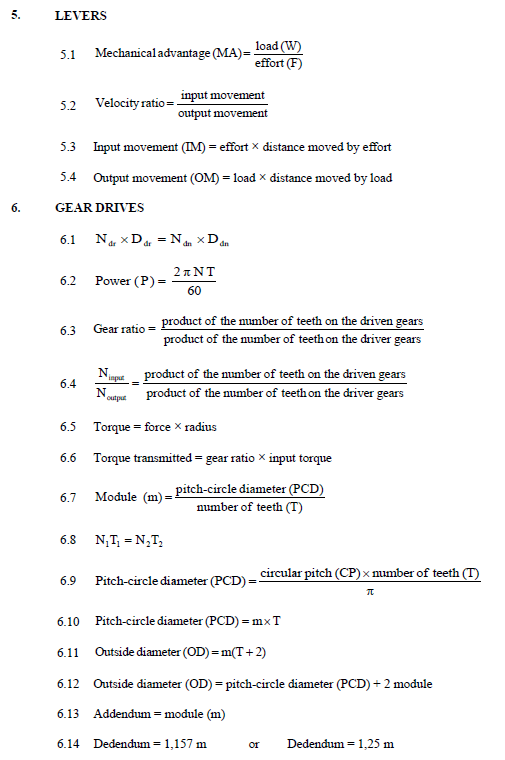

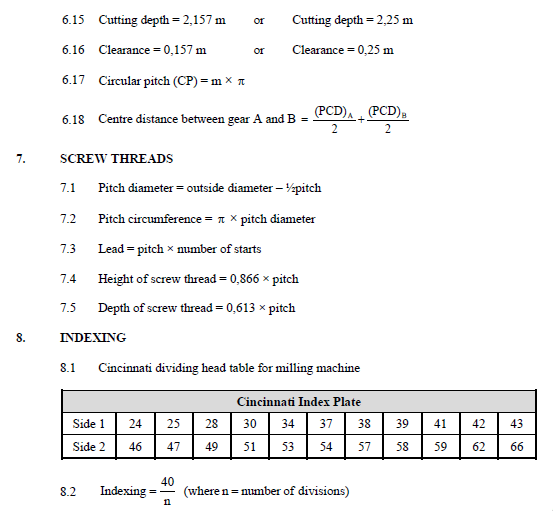

FORMULA SHEET