AGRICULTURAL TECHNOLOGY GRADE 12 MEMORANDUM - AMENDED SENIOR CERTIFICATE EXAMS PAST PAPERS AND MEMOS MAY/JUNE 2018

Share via Whatsapp Join our WhatsApp Group Join our Telegram GroupAGRICULTURAL TECHNOLOGY

GRADE 12

AMENDED SCE PAST PAPERS AND MEMOS

MAY/JUNE 2018 2018

MEMORANDUM

SECTION A

QUESTION 1

1.1

1.1.1 C✔✔ (2)

1.1.2 D✔✔ (2)

1.1.3 B✔✔ (2)

1.1.4 B✔✔ (2)

1.1.5 C✔✔ (2)

1.1.6 D✔✔ (2)

1.1.7 A✔✔ (2)

1.1.8 B✔✔ (2)

1.1.9 C✔✔ (2)

1.1.10 D✔✔ (2) (10 x 2) (20)

1.2

1.2.1 yellow✔✔ (2)

1.2.2 cell phone/two way radio✔✔ (2)

1.2.3 smart controller✔✔ (2)

1.2.4 oil✔✔ (2)

1.2.5 zinc✔✔ (2) (5 x 2) (10)

1.3

1.3.1 D ✔✔ (2)

1.3.2 G✔✔ (2)

1.3.3 A✔✔ (2)

1.3.4 B✔✔ (2)

1.3.5 E✔✔ (2) (5 x 2) (10)

TOTAL SECTION A: 40

SECTION B

QUESTION 2: MATERIALS AND STRUCTURES

2.1 The alloy metal that is specifically used to manufacture the following products and TWO reasons why that metal is used.

2.1.1 Milk tanks

Stainless Steel✔ (1)

- Resistant to air, water and many chemical acids and alkali.✔

- Resistance against corrosion.✔

- Can be welded well.✔ (Any 2) (2)

2.1.2 Fittings for hot water copper pipes

Brass✔ (1)

- Strength✔

- Machinability✔

- Wear resistance✔

- Hardness✔

- Corrosion resistance✔ (Any 2) (2)

2.1.3 Hammering tools that can be used in explosive atmospheres.

Bronze(Beryllium Copper)✔ (1)

- Does not generate sparks✔

- Low friction✔

- Resist corrosion✔ (Any 2) (2)

2.2 TWO hot working processes that can be used to change the structural properties of brass.

- Annealing✔

- Stress relieving✔

- Tempering✔ (Any 2) (2)

2.3

2.3.1 TWO reasons for preferring fibre-glass troughs instead of concrete troughs for cattle.

- Easy to move around. (Light)✔

- Easy to fix/repair✔

- Rust resistance✔ (Any 2) (2)

2.3.2 Description of 'resin' as used in the manufacturing in fibreglass products.

- They are low viscosity fluids✔that can be transformed✔to tough flexible solids by adding✔a hardening agent. (Any 2) (2)

2.3.3 TWO methods used to join fibreglass parts.

- Pop rivet✔

- Bolt and nut✔

- Fibreglass✔

2.4 FIVE reasons why Vesconite is proven as the best material in the manufacture of bushes.

- It is ideal for many marine applications.✔

- It does not swell and seize.✔

- It remains hard.✔

- It does not delaminate.✔

- It has low friction.✔

- It does not corrode.✔

- Bushes can easy be removed.✔

- Does not contain any asbestos (healthy)✔/Safer to work with.

- Easy to machine.✔ (Any 2) (2) (Any 5) (5)

2.5 Description of how an adhesive should be applied to a surface to ensure sufficient cohesion.

- First clean the surface properly.✔

- If the surface is very slippery, the surface can be sanded to make it coarse.✔

- Apply a thin base coat if the surface is very porous.✔

- Apply only a thin layer of adhesive because a thick layer of adhesive will result in a weak joint.✔

- Apply adhesive to both surfaces.✔ (Any 4) (4)

2.6

2.6.1 The procedure that must be followed when testing the earth system of an electric fence.

- Firstly short out the live fence line to the ground.✔

- Switch the energizer ON.✔

- Measure the voltage between the GROUND and the Earth Spike with a meter.✔

- If this is above 200 volts the earth installation is inefficient.✔ (4)

2.6.2 TWO examples of the application of electric fences on the farm.

- Protection✔/Farm security purposes.

- Temporary fences.✔

- Fencing dangerous animals.✔ (Any 2) (2)

2.6.3 THREE alternative energy sources that can be used to provide energy for an electrical fence.

- Wind✔

- Solar✔

- Water✔ (3) [35]

QUESTION 3: ENERGY

3.1 The TWO parts labelled as A and B of the turbine, and the function of each.

A | Propeller-type blades✔ | Shaped to catch the wind, transfer wind energy into drive/kinetic/rotational energy.✔ (2) |

B | Generator✔ | Generates electricity and send it to the transformer and electric grid.✔ (2) |

3.2 3.2.1 The working of the solar hot water geyser.

- The sun heats the water in the glass tubes, the heated water rise to the highest point in the system.✔

- The heated water enters the geyser through a closed copper pipe network that runs through the geyser.✔

- The hot water inside the copper pipes heats up the cold water inside the geyser.✔

- The cooled water flows downwards back to the solar tubes where it is reheated.✔ (4)

3.2.2 FOUR benefits of using solar energy to heat water.

- Environmentally friendly energy source/No pollution.✔

- Installation is relative cheap and simple.✔

- Solar power is limitless.✔

- Transition losses are limited.✔

- Does not use a lot of space.✔ (Any 4) (4)

3.3

3.3.1 TWO geological aspects that should be investigated to determine the specific area to construct a geothermal energy plant.

- Rocks that is soft enough to drill✔/Type of rock

- Volcanic activities✔

- Accessibility✔ (Any 2) (2)

3.3.2 TWO advantages of a geothermal energy plant.

- A geothermal system does not create any pollution.✔

- The cost of the land to build a geothermal power plant on is usually less.✔

- Because geothermal energy is very clean, you may receive tax cuts, and/or no environmental bills.✔

- No fuel is used to generate the power.✔

- The running costs for the plants are very low.✔

- The overall financial impact of these plants is positive.✔ (Any 2) (2)

3.4

3.4.1 TWO alternative fuels that are obtained from plants.

- Ethanol✔

- Methanol✔

- Biodiesel✔ (Any 2) (2)

3.4.2 TWO crops that can be used to produce bio-fuel.

- Sugar cane✔

- Sunflower✔

- Maize✔

- Vegetables✔

- Sorghum✔ (Any 2) (2) [20]

QUESTION 4: SKILLS AND CONSTRUCTION PROCESSES

4.1

4.1.1 The origin and purpose of the cloud formed around a welding area.

- The inserted gas✔is fed through the pipe and nozzle and exit through the holes in the nozzle.

- The function is to shield the molten puddle✔from oxygen contamination.✔ (3)

4.1.2 The procedure that must be followed when the feed wire burns onto the copper welding tip.

- Release the trigger.✔

- Take a plier and cut the blob from the welding tip.✔

- Use a file and file the welding tip.✔

- Ensure that the feeding wire is separated from the tip and continue welding.✔ (4)

4.1.3 TWO circumstances that can cause the feed wire from melting onto the welding tip.

- Gap between the nozzle and work piece is too small.✔

- Wire feed is too slow.✔

- Welding too close to your material.✔

- Building up too much heat on the tip of the welding torch.✔ (Any 2) (2)

4.1.4 THREE causes of cracks forming on the welding bead when performing MIG welding.

- Root gap too small in restrained joint.✔

- Current too high.✔

- Deep narrow weld bead. ✔(with centre line cracking)

- Inadequate filling of crater.✔

- Inadequate pre-heat on high tensile and low alloys.✔

- Incorrect composition of electrode.✔ (Any 3) (3)

4.2

4.2.1 Description of 'shrinking' as it occurs in a welding joint.

- When metal is heated it expands and when cooling down it shrink.✔

- The shrinking of welded metal and weld runs cause distortion of metal when they cool down.✔

- Shrinking take place in all directions simultaneously and therefore cause various kinds of distortion.✔ (3)

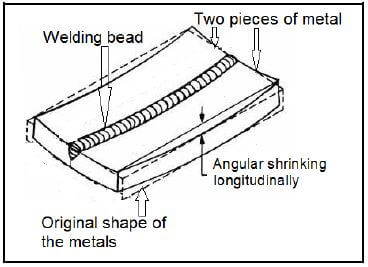

4.2.2 A free hand drawing to illustrate angular shrinking longitudinally on a welded project. The dimensions of the two flat bar pieces that must be welded together is 50 mm x 10 mm x 100 mm.

- Two pieces of metal✔ (1)

- Welding bead✔ (1)

- Shrinking✔ (1)

- Original shape of the metals✔ (1)

4.2.3 Prevention of metal distortion when welding on metal.

- Pre-setting✔

- Welding of patch work✔

- Clamping✔

- Spot welding✔ (Any 2) (2)

4.3 4.3.1 Reasons why sunglasses are not recommended when cutting with the oxy-acetylene set.

- They do not filter the ultraviolet light effectively.✔

- Sunglasses will not protect your eyes sufficiently from flying sparks.✔ (2)

4.3.2 The possible end results for the gas cylinder when it accidentally topples over.

- The main valve may break off.✔

- The cylinder will turn into a missile and cause extreme damage.✔ (explodes) (2)

4.3.3 TWO types of metals that can be cut with an oxy-acetylene welding set.

- Mild steel✔

- Carbon steel✔

- Cast iron✔

- Stainless steel✔ (Any 2) (2)

4.4 Technical advice to a farmer who wants to purchase a plasma cutting machine for general use on the farm.

- Buy a machine according to the thickness of the metal that must be cut.✔

- You need a compressor large enough for the required working pressure✔

- Buy a well-known brand/quality.✔ (Any 2) (2)

4.5 FOUR pieces of personal protective equipment (PPE) that must be used when doing plasma cutting.

- Fireproof gloves✔

- Face shield✔

- Flame resistant clothing✔

- Leather shoes✔ (4)

4.6 Factors that cause poor cutting performance when using the plasma cutting machine.

- The working pressure of the machine is too low.✔

- A too small compressor that provides insufficient air pressure.✔

- Water in the air system.✔

- Electrode and tip are worn.✔

- Use of a too thin air hose.✔

- Blocked air filters.✔ (Any 2) (2)

[35]

QUESTION 5: TOOLS, IMPLEMENTS AND EQUIPMENT

5.1

5.1.1 TWO disadvantages of mechanization on the farm.

- High initial input cost✔

- Higher salaries✔

- Skilled labourers are needed✔

- Labour regulations✔

- Loss of jobs✔ (Any 2) (2)

5.1.2 TWO examples of fixed capital on the farm.

- Land✔

- Buildings✔

- Kraals✔

- Boreholes✔

- Pumps✔ (Any 2) (2)

5.2 TWO functions of a shear bolt used in the drive system of a baling machine.

- Prevents heavy objects from being taken into the baler.✔

- Protects the pick-up if it is impeded by anything.✔

- Protects the auger if it becomes overloaded.✔ (Any 2) (2)

5.3 THREE parts of a clutch assembly A, B and C.

A = Pressure plate✔

B = Release bearing✔

C = Clutch plate✔ (3)

5.4 Is it possible that a vehicle can turn around a bend if the differential is locked? Explain your answer.

- No✔

- When the vehicle turn around a bend the wheels will momentarily turn around a common centre,✔

- but when the differential is locked this cannot happen because the half axle shaft of the outer wheel cannot revolve faster than that of the inner wheel.✔ (3)

5.5 TWO advantages of using a bearing in a drive system.

- Bearings increase efficiency.✔

- Bearings reduce friction and wear.✔

- Allows extended use at high speeds.✔

- Avoids overheating and premature failure of a drive system.✔ (Any 2) (2)

5.6 TWO advantages of thermoplastic universal joints.

- They are light weight✔

- They have negligible backlash✔

- Are corrosion resistant✔

- They have the capability for high-speed operation✔

- They are self-lubricating✔

- Does not delaminate or soften✔

- Easy removable✔

- Easy to machine✔

- Does not swell or seize✔ (Any 2) (2)

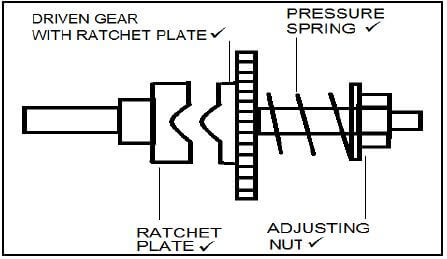

5.7 Freehand drawing of a ratchet type slip clutch and indicating of the following components.

- Ratchet plate (1)

- Pressure spring (1)

- Driven gear with ratchet plate (1)

- Adjusting nut (1)

(4)

(4)

5.8 Reasons why it is better moving heavy loads with a rear attachments rather than with the front-end loader.

- Rear tyres are better suited/stronger to carry the extra weight.✔

- There is less chance of side overturns because the bale is not lifted high.✔

- More stress on the front wheels causes difficult steering.✔ (Any 2) (2)

5.9 The situation in case the top link between a tractor and plough are removed when ploughing.

- The back of the plough will tend to lift up out of the soil✔or the nose of the tractor will tend to lift up.✔ (2)

5.10 Parts where a quick coupling can be connected to a tractor.

- Two lifting arms✔

- Top link✔ (2)

5.11 THREE systems on a combine harvester that must be set to prevent the loss of cornels during harvesting.

- The pickup system must be set correctly.✔

- Set the drum speed correctly.✔

- Sieves must be set correctly.✔

- Gears/pulleys.✔ (Any 3) (3)

5.12 THREE aspects to consider in order to prevent a hammer mill from vibrating.

- Hammers should be checked to ensure that their mass is the same.✔

- When replacing hammers, the whole set of hammers should be replaced at the same time.✔

- Hammers that are reversed should be replaced in its original place.✔

- Nothing should be added or removed from the rotor.✔

- Run the hammer mill at the correct speed.✔

- The hammer mill must be properly anchored.✔ (Any 3) (3)

5.13 TWO places on a tractor where the automatic depth control mechanism can be installed.

- Where the top link is fitted.✔

- In the differential housing.✔

- At the base of the lifting arms.✔ (Any 2) (2)

5.14 THREE advantages of transmission oil in tractor hydraulic systems.

- Not compressible✔

- Good lubrication qualities✔

- Remains liquid over a large temperature range✔

- Not volatile✔

- Relatively cheap✔

- Easily conductible in pipes✔

- Flows through filters, pipes, oil pumps and cylinders with ease✔

- Contains detergents that keeps parts clean✔

- Contains anti-foam detergent✔

- Good cooling qualities✔ (Any 3) (3)

5.15 A diesel tank with a surface area of 9 m² needs to be painted. Use a corrosion resistant paint with a covering capability of 3 m² per litre.

Determine how much paint is required by showing all calculations, if TWO coats of paint are required on the tank.

- Paint required = 9 m² / 3 m² (covering capability per litre)✔

= 3 litres needed

= 2 coats X 3 litres per coat✔

= 6 litres of paint✔ (3)

[40]

QUESTION 6: WATER MANAGEMENT

6.1 Completion of the table regarding different irrigation systems.

6.1.1 Centre pivot irrigation✔ (1)

6.1.2 PVC pipes with plastic or brass sprinklers✔ (1)

6.1.3 Sprinklers can irrigate areas such as small farms, parks and pastures✔ (1)

6.1.4 Lateral wheel line irrigation✔ (1)

6.2 FOUR disadvantages of flood irrigation. (4)

- When water supply is weak flood irrigation is impossible.✔

- Surface gradient (steep) leads to erosion.✔

- Infiltration tempo not constant.✔

- Drainage problems.✔

- High costs of levelling of land.✔

- Increase salinity in soil.✔ (Any 4) (4)

6.3 The functions of the following irrigation system parts.

6.3.1 Sand filter Prevent blockage of sprinkler nozzles / filters the water.✔ (1)

6.3.2 Sprinkler Provide water to plants.✔ (1)

6.3.3 Pump Provide water to the system / sprinklers.✔ (1)

6.3.4 Solenoid valve Controlling the water flowing through the system.✔ (1)

6.3.5 One way valve Prevent water from flowing back to the pipe.✔ (1)

6.4

6.4.1 TWO devices, A and B.

A Tensio meter✔

B Evaporation pan/Class – A pan✔ (2)

6.4.2 The main purpose of the devices shown.

- To determine the water evaporation rate in a specific field.✔ (1)

6.5 TWO devices that are used to control garden watering systems.

- Electronic irrigation timer✔

- Mechanical timer✔ (2)

6.6 Operation of a septic tank system.

- Sewage is broken down by anaerobic bacteria in the first tank.✔

- Very little solids remain when the watery sewerage flows to the second tank.✔

- Only liquid sewage remains and drains away through the outlet pipe or stone trench.✔ (3)

6.7 THREE points to consider when choosing a suitable location for installing a septic tank.

- The tank should not be built near boreholes and drinking water installations.✔(water source)

- A suitable distance away from the house.✔

- Not near traffic.✔

- Not near where people eat, wash or work regularly.✔ (Any 3) (3)

6.8 The operation of a pipe drainage system.

- The water drains through the surface gravel✔and seeps into the pipe's perforations✔before traveling out the end of the pipe into an area that can accommodate extra water.✔ (3)

6.9 THREE types of water purification systems that make use of a membrane to purify household water.

- Reverse osmosis✔

- Faucet filters✔

- Jug or pitched filter✔

- Inline filter✔

- Whole house purification system✔ (Any 3) (3)

[30]

TOTAL SECTION B: 160

GRAND TOTAL: 200

(4)

(4)