MECHANICAL TECHNOLOGY GRADE 12 MEMORANDUM - NSC PAST PAPERS AND MEMOS FEBRUARY/MARCH 2018

Share via Whatsapp Join our WhatsApp Group Join our Telegram GroupMECHANICAL TECHNOLOGY

GRADE 12

NSC PAST PAPERS AND MEMOS

FEBRUARY/MARCH 2018

MEMORANDUM

QUESTION 1: MULTIPLE-CHOICE QUESTIONS

1.1 C ✔ (1)

1.2 C ✔ (1)

1.3 B ✔ (1)

1.4 D ✔ (1)

1.5 C ✔ (1)

1.6 D ✔ (1)

1.7 A ✔ (1)

1.8 A ✔ (1)

1.9 A ✔ (1)

1.10 B ✔ (1)

1.11 A ✔ (1)

1.12 C ✔ (1)

1.13 B ✔ (1)

1.14 A ✔ (1)

1.15 D ✔ (1)

1.16 A ✔ (1)

1.17 C ✔ (1)

1.18 A ✔ (1)

1.19 B ✔ (1)

1.20 A ✔ (1) [20]

QUESTION 2: SAFETY

2.1 Spring tester

- Use correct attachments of the valve spring tester to compress the spring. ✔

- Do not exceed the prescribed pressure. ✔

- Ensure that the spring does not slip out. ✔

(ANY 2 x 1) (2)

2.2 Welding helmet

- To protect your eyes against the dangerous ultra-violet rays. ✔

- To protect your skin against the dangerous ultra-violet rays. ✔

- To protect your eyes against the sparks. ✔

- To protect your skin against the sparks. ✔

(ANY 1 x 1) (1)

2.3 Spot welding

- To prevent the electrodes from overheating. ✔ (1)

2.4 Testers

2.4.1 Brinell tester

- The tester must be mounted on the rigid spot on a workbench ✔

- The force must be applied at an angle of 90° to the test piece ✔

- Do not exceed the prescribed load ✔

- Make sure the test piece is placed securely into position ✔

(ANY 1 x 1) (1)

2.4.2 Tensile tester

- Make sure all safety guards are in place ✔

- Do not exceed the prescribed load ✔

- See that the test piece is securely placed in position ✔

- Make sure the dial indicator is mounted properly ✔

(ANY 1 x 1) (1)

2.4.3 Torsion tester

- Fasten the tester to the workbench ✔

- When you add pieces of different mass, you should attach them very gently otherwise you could get a skew reading of the torsion on the rod ✔

- Get specification (torsion) of the different materials and of the size rods you would like test ✔

(ANY 1 x 1) (1)

2.5 Bearing puller

- Perpendicular or 90° to the bearing. ✔ (1)

2.6 Cylinder leakage tester

2.6.1

- To prevent damage to the seals and tester ✔

- To ensure the correct reading ✔

(ANY 1 x 1) (1)

2.6.2

- To prevent damage to the tester and spark plug hole or injector hole ✔

- To ensure the correct reading ✔

(ANY 1 x 1) (1) [10]

QUESTION 3: TOOLS AND EQUIPMENT

3.1 Testers

3.1.1 Cylinder leakage tester

- Is used to determine a leakage in the cylinder✔.

- Determine the volume of leakage✔ (2)

3.1.2 Fuel pressure tester

- Is used to test the fuel operating pressure in the system ✔

- Is used to test the fuel pressure in the fuel line that runs to the direct injection. ✔ (2)

3.1.3 Torsion tester

- Is used to investigate the relationship between momentum or torque applied to material ✔

- Is used to investigate influence of material length on torsional deflection. ✔ (2)

3.2 Reasons for high CO2 reading

- Lean fuel mixture setting ✔

- Low compression ✔

- Faulty high tension leads ✔

(ANY 2 x 1) (2)

3.3 MIGS/MAGS-welding

3.3.1 Reasons for using inert gas during MIGS/MAGS welding

- Stabilises the arc on the parent metal ✔

- Shields the arc and weld pool from atmospheric gases like oxygen ✔ (2)

3.3.2 Advantages of MIGS/MAGS welding

- Can weld in any position ✔

- Less operator skill required ✔

- Continuous welding can be done ✔

- Causes less deformation ✔

- Faster than arc welding ✔

- Minimal post weld cleaning ✔

- No slag removal is required ✔

(ANY 2 x 1) (2) [12]

QUESTION 4: MATERIALS

4.1 Characteristics of structures

4.1.1 Austenite

- Soft ✔

- Coarse grain structure ✔

- Non-magnetic ✔

(ANY 2 x 1) (2)

4.1.2 Ferrite

- Soft ✔

- Ductile ✔

- Magnetic ✔

(ANY 2 x 1) (2)

4.2 Iron-carbon equilibrium diagram

4.2.1 Lower critical point (AC1) of steel

- The structure starts to change ✔✔ (2)

4.2.2 Higher critical point (AC3) of steel

- The structure turns into complete Austenite ✔✔

- The steel completely loses its magnetic properties ✔✔

- The structure turns into its finest grain size ✔✔

(ANY 1 x 2) (2)

4.3 Reasons to enhance properties of a crankshaft

- To produce a hard face with a tough core. ✔

- To induce toughness ✔ (2)

4.4 Reasons for the tempering of a camshaft

- To increase the lifespan of the camshaft ✔

- To eliminate brittleness caused by hardening. ✔

(ANY 2 x 1) (2)

4.5 Heat treatment process on piston rings

- Hardening ✔ (1) [13]

QUESTION 5: TERMONOLOGY

5.1 Key dimensions

5.1.1 The width of the key

- Width = D

4

= 120 ✔

4

= 30 mm ✔ (2)

5.1.2 The thickness of the key

- Thickness = D

6

= 120 ✔

6

= 20 mm ✔ (2)

5.1.3 The length of the key

- Length = D × 15 ✔

= 120 × 15 ✔

= 180 mm (2)

5.2 Indexing

- Indexing = 40

n

= 40 ÷ 2 ✔

124 2

= 20 ✔

62

No full turns and 20 holes in a 62 hole circle (3)

5.3 Height of screw the screw thread

- H = 0 866

= 3 × 0 866 ✔

= 2 6 mm ✔ (2)

5.4 Gear terminology

5.4.1 Addendum = m

- = 3 mm ✔ (1)

5.4.2 Dedendum

- = 1,157 m or =1,25 m

= 1,157 x 3 ✔ =1,25 x 3 ✔

= 3,47 mm ✔ =3,75 mm ✔ (2)

5.4.3 Clearance

- = 0,157 m or =0,25m

= 0,157 x 3 ✔ =0,25 x 3 ✔

= 0,47 mm ✔ =0,75 mm ✔ (2)

5.4.4

- Module = PCD

T

PCD = m × T ✔

= 3 × 48 ✔

= 144 mm ✔(2)

5.4.5

- OD = PCD + 2m ✔

= 144 + 2(3)

= 144 + 6

= 150 mm ✔ (2)

5.4.6 Cutting depth

- = 2,157 m ✔ or =2,25m ✔

= 2,157 x 3 =2,25 x 3

= 6,47 mm ✔ =6,75 mm ✔ (2)

5.4.7 Circular pitch

- = m x π✔

= 3 x π

= 9,42 mm ✔ (2)

5.5 Setting of the lathe and cutting tool to cut a metric V-screw thread:

- Set the lathe to the correct speed for screw cutting ✔

- Set the lead screw according to the required pitch ✔

- Set the dial gauge to position with the required worm gear ✔

- Set the compound slide to half the included angle of the thread (30°) ✔

- Set the cutting tool centre height and 90° to the work piece with the help of a centre gauge ✔

- Set cross slide and compound slide collars to zero with the tool touching the work piece ✔ (6) [30]

QUESTION 6: JOINING METHODS

6.1 Welding defects

6.1.1 Slag inclusion

- Welding speed too fast ✔

- Not removing the slag from the previous weld run before welding the next run ✔

- Current too low ✔

(ANY 2 x 1) (2)

6.1.2 Incomplete penetrations

- Welding speed too fast ✔

- Faulty joint design ✔

- Electrode too large ✔

- Current too low ✔

(ANY 2 x 1) (2)

6.2 Atmospheric contamination during MIGS/MAGS welding

- Inadequate shielding gas flow ✔

- Excessive shielding gas flow ✔

- Severely clogged nozzle ✔

- Damaged gas supply system ✔

- Excessive wind in the welding area ✔

(ANY 2 x 1) (2)

6.3 Nick break test

- Make a hacksaw cut at both edges, through the centre of the weld ✔

- Place the saw-nicked specimen on two steel supports ✔

- Use a sledge hammer to break the specimen by striking it in the zone where you made the saw cuts ✔

- Defects like incomplete fusion, slag inclusion and brittleness will be exposed in the break ✔

- Any defects bring it to the attention to the welder to rectify it ✔ (5)

6.4 Reasons for destructive tests

6.4.1 Bend test

- To determine the ductility/elongation ✔✔ of the weld metal. (2)

6.4.2 Machinability test

- To determine the welds hardness ✔ and its strength. ✔ (2)

6.5 X-ray test

- To detect internal defects in the weld metal✔✔ (2)

6.6 Weld crater

- Forms where welding is resumed at the bottom of the previous weld instead of on the top ✔✔ (2)

6.7 MIGS/MAGS welding

6.7.1 Welding process

- MIGS/MAGS welding ✔ (1)

6.7.2 Labelling

- A. Parent metal ✔

- B. Arc ✔

- C. Electrode wire ✔

- D. Gas shroud ✔

- E. Shielding gas ✔ (5) [25]

QUESTION 7: FORCES

7.1 Resultant

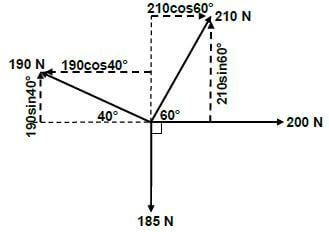

- ∑HC = 200 + 210cos60 - 190cos 40º ✔

= 200 + 105 - 145.55 ✔ ✔ ✔

= 159,45 N ✔ (4) - ∑VC = 210sin 60º + 190sin 40º - 185

= 181,87 + 122,13 - 185 ✔✔

= 119 N ✔ (3)

OR

Horizontal components | Magnitudes | Vertical components | Magnitudes |

200N | 200 N ✔ | 210NSin60º | 181,87N ✔ |

210N | 105 N ✔ | 190NSin40º | 122,13 N ✔ |

190N Cos40º | -145,45 N ✔ | -185 N | -185 N |

TOTAL | 159,45 N ✔ | TOTAL | 119 N ✔ |

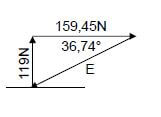

2 2 2

- E2 = HC2 + VC2

E = √ 159,452 + 1192

E = 198,96 N ✔ ✔ (3)

(3)

Tan θ = VC✔

HC

= 119

159,45N

= 36,74º E

E = 198,96N 36,73º south of west ✔

OR

= 36º 44' minutes south of west ✔ (3)

7.2 Stress and Strain

7.2.1 Resistance area

- A = π (D2 - d2)

4

= π (0,0562 - 0,0382) ✔

4

= 1,33 × 10-3m2 ✔ (2)

7.2.2 Stress

- Stress = force

area

stress = 20 × 103

1,33 × 10-3

=15037593,98 Pa

Stress= 15,04MPa ✔(3)

7.2.3 Strain

- Strain = Δl ✔

OL

Strain = 50 - 49,975

50

Strain = 0,025

50

= 0,5 × 10-3 ✔ (3)

7.2.4 Young’s Modulus of Elasticity

- Youngs Modulus of Elasticity = Stress ✔

Strain

E = 15,04 × 106

0,5 10-3

= 30,08 × 109 Pa

= 30,08 GPa ✔ (3)

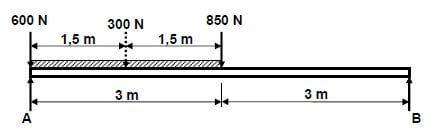

7.3 Moments

7.3

Calculate B. Moments about A:

- ∑LHM =∑ RHM

( B × 6) = (300 × 1,5) + (850 × 3) ✔

6B = 3000 ✔

6 6

B = 500N ✔

Calculate A. Moments about B:

- ∑RHM =∑LHM

(A × 6) =(850 × 3) +(300 × 4,5) + (600 × 6)

6A = 2550 + 1350 + 3600

6A = 7500 ✔

6 6

B = 1250N ✔(6) [30]

QUESTION 8: MAINTENANCE

8.1 Reason using SAE 20W50

- This to ensure that the oil is able to satisfy the operational ✔ requirements over a range of temperature ✔ from start-up to running hot. (2)

8.2 Maintain V-belt drive systems

- Check the contact surfaces of the pulley to prevent the belt from being damaged.✔

- Check the belt condition and replace if it is worn.✔

- Correct installation procedure must be followed. ✔

- Belt drives should be well guarded to prevent foreign objects to come into contact with the belts and pulleys.✔

- Keep guard mesh free of papers, rags, etc. that can cause insufficient air flow. ✔

- Check that the belt deflection is according to specification. ✔

- Store replacement belts in a cool, well ventilated place. ✔

- Correct alignment of pulleys. ✔

(ANY 2 x 1) (2)

8.3 Flash point

- It is the lowest temperature ✔ at which the oil gives off vapours ✔ which can ignite. ✔ (3)

8.4 Maintaining cutting fluid

- Avoid contamination of the cutting fluid by draining and regularly replacing it. ✔

- Always clean the machine's splash tray of metal cutting after use. ✔

- Regularly wipe cutting fluid splashes of machine parts. ✔

- Ensure that the sump is topped up from time to time and check that there is sufficient flow of cutting fluid to the cutting tool. ✔

(ANY 2 x 1) (2)

8.5 Functions of the clutch plate

- It provides friction between the flywheel and pressure plate. ✔

- It serves as a link between the clutch and the gearbox main shaft. ✔ (2)

8.6 Reasons for skimming the flywheel

- To remove the grooves caused by the clutch plate. ✔

- To ensure a full contact surface between the flywheel and the clutch plate. ✔

- To prolong the life of the clutch plate. ✔

(ANY 2 x 1) (2)

8.7 Properties of grease

- It must be water resistant, it must not mix with water ✔

- Prevents rust/corrosion ✔

- Good for load pressures ✔

- High melting point ✔

- Low freezing point ✔

- Prevent gumming ✔

- Be able to lubricate ✔

- High viscosity ✔

(ANY 2 x 1) (2) [15]

QUESTION 9: SYSTEMS AND CONTROL

9.1 Gear drives

9.1.1 Rotation frequency of input shaft

- NA = TB × TD × TF

NF TA × TC × TE

NA = TB × TD × TF × NF

TA × TC × TE

= 30 × 46 × 80 × 160

20 × 18 × 42

= 1401,90r/min (3)

9.1.2 Velocity ratio

- VR= NA

NF

VR= 1401,90

160

= 8,76: 1 ✔ (2)

9.2 Belt drives

9.2.1 Rotation frequency of driver pulley

- NDR × DDR = NDN × DDN

NDR = NDN × DND

DDR

= 733,33 × 0,36

0,24

= 200r/min (3)

9.2.2 Power transmitted

- P = (T1 - T2)πDn

60

P= (360 - 90)π × 0,36 × 733,33

60

= 3732,20 Watts

=3,73 kW (2)

9.2.3 Belt speed

- Belt speed = πDN

60

= π × 0,36 × 733,33

60

= 13,83m.s-1 ✔ (2)

9.3 Hydraulics

9.3.1 Fluid pressure

- AB = πD2

4

= π0,042

4

= 1,26 × 10-3m2 - PB = F

AB

= 275

1,26 × 10-3

= 218253,97 pa

or

= 218,25 kPa (5)

9.3.2 Diameter of piston B

- PB =PA

PB = FB

AB

AB = FB

PB

AB = 5,56 × 103

218,25 × 103

AB = 25,48 × 10-3m2

AB = πD2

4

DB = √AB × 4

π

= √25,48 × 10-3 × 4

π

=0,18 m

or

=180 mm (4)

9.4 ABS

- ABS prevents wheels from skidding ✔ when breaking hard ✔ in difficult conditions. (2)

9.5 ECU

- Electronic Control Unit ✔ (1)

9.6 Traction Control

- Prevent wheels from spinning. ✔

- Improves road holding ✔

(ANY 1 x 1) (1) [25]

QUESTION 10: TURBINES

10.1 Reaction turbines

- Francis ✔

- Kaplan ✔

- Tyson ✔

Gorlov ✔ (ANY 2 x 1) (2)

10.2 Supercharger boost

- Boost refers to the increase in intake manifold pressure ✔ that exceeds normal atmospheric pressure✔ (2)

10.3 Blowers

- Roots ✔

- Centrifugal ✔

- Vane-type ✔

- Twin screw type ✔

(ANY 2 x 1) (2)

10.4 Gas turbine

- A = Clean air inlet ✔

- B = Compression ✔

- C = Combustion ✔

- D = Exhaust ✔

- E = Turbine ✔

- F = Combustion chamber ✔ (6)

10.5 Application of a gas turbine

- Jet engines ✔

- Naval ships ✔

- Hi-performance vehicles and boats ✔

- Generating electricity ✔

(ANY 2 x 1) (2)

10.6 Advantages of a gas turbine

- Less complex than internal combustion piston engines ✔

- Only one moving part (Common shaft for: compressor and turbine) ✔

- Operate at higher revolutions per minute ✔ (ANY 2 x 1) (2)

10.7 Waste gate

- A waste gate is a valve that diverts exhaust gases away from the turbine wheel ✔ to regulate the turbine/compressor speed and boost.✔ (2)

10.8 Oil cooler

- To cool the oil ✔ that lubricates the turbocharger bearings and shaft. ✔ (2) [20]

TOTAL: 200

(3)

(3)