MECHANICAL TECHNOLOGY PAPER 2 GRADE 12 (AUTOMOTIVE) QUESTIONS - 2018 SEPTEMBER PREPARATORY EXAM PAPERS AND MEMOS

Share via Whatsapp Join our WhatsApp Group Join our Telegram GroupMECHANICAL TECHNOLOGY (AUTOMOTIVE)

GRADE 12

NATIONAL SENIOR CERTIFICATE

SEPTEMBER 2018

INSTRUCTIONS AND INFORMATION

- Write your NAME on your ANSWER BOOK.

- Read ALL the questions carefully.

- Answer ALL the questions.

- Number the questions correctly according to the numbering system used in this question paper.

- Start EACH question on a NEW page.

- Show ALL calculations and units. Round off final answers to TWO decimal places.

- Candidates may use non-programmable scientific calculators and drawing instruments.

- Take the value of gravitational acceleration should be taken as 10 m/s2.

- All dimensions are in millimetres, unless stated otherwise in the question.

- A formulae sheet is attached to the question paper.

- Write neatly and legibly.

- Use the criteria below to assist you in managing your time management.

| QUESTION | CONTENT COVERED | MARKS | TIME |

| Generic | |||

| 1 | Multiple-choice questions | 6 | 6 minutes |

| 2 | Safety | 10 | 10 minutes |

| 3 | Materials | 14 | 14 minutes |

| Specific | |||

| 4 | Multiple-choice questions | 14 | 10 minutes |

| 5 | Tools and Equipment | 23 | 20 minutes |

| 6 | Engines | 28 | 25 minutes |

| 7 | Forces | 32 | 25 minutes |

| 8 | Maintenance | 23 | 20 minutes |

| 9 | Systems and Control (Automatic Gearbox) | 18 | 20 minutes |

| 10 | Systems and Control (Axles, Steering Geometry and Electronics) | 32 | 30 minutes |

| TOTAL | 200 | 180 minutes | |

QUESTION 1: MULTIPLE-CHOICE QUESTIONS (GENERIC)

Various options are provided as possible answers to the following questions. Choose the correct answer and write only the letter (A–D) next to the question number (1.1–1.6) in the ANSWER BOOK, for example 1.7 A.

1.1 Which of the following laws in South Africa protect the people living with HIV/Aids?

- Occupational Health and Safety Act (OHS)

- The Bill of Rights

- The Labour Relations Act

- All of the above(1)

1.2 Identify the safety measure below that is applicable to the bench grinder in terms of the Occupational Health and Safety Act:

- All surfaces of the machine must be well oiled

- Guards must be removed when grinding

- Wear safety goggles when grinding

- Ensure that the machine is running (1)

1.3 The following safety precautions must be followed when handling gas bottles:

- Wear approved PPE to shield the skin from the arc rays

- Use completely insulated electrode holders

- Wear leather spats and safety boots when welding

- Never stack cylinders on top of one another (1)

1.4 The process of relieving stresses, set up by cold working is termed …

- annealing.

- hardening.

- tempering.

- normalising. (1)

1.5 Materials can be tested differently in the workshop and industry.

How can metals be tested?

- Sound test

- Bend test

- Filing test

- All of the above. (1)

1.6 Which of the following carbon steels has short, very white or light yellow carrier lines with forking and considerable many star-like bursts?

- Low carbon steel

- High carbon steel

- Cast iron

- Medium carbon steel (1)

[6]

QUESTION 2: SAFETY (GENERIC)

2.1 List FOUR unsafe conditions in a mechanical workshop. (4)

2.2 Describe at least some of the procedures to follow when assessing a first aid situation. (2)

2.3 Give the advantages of the following workshop layouts:

2.3.1 Product layout of machines (2)

2.3.2 Process layout of machines (2)

[10]

QUESTION 3: MATERIALS (GENERIC)

3.1 State the purpose of case hardening mild steel. (2)

3.2 The hardness that can be achieved with a given heat-treatment depends on which THREE factors? Mention these three factors. (3)

3.3 List FOUR kinds of quenching mediums. (4)

3.4 Why is it important that hardened steel be tempered as soon as possible during the heating process? (2)

3.5 Tabulate the findings on the different tests on the materials indicated below.

| Material | |||

| Type of test | Mild Steel | High Speed Steel | Cast Iron |

| Sound Test | 3.5.1 | 3.5.2 | 3.5.3 |

(3)

[14]

QUESTION 4: MULTIPLE-CHOICE QUESTIONS (SPECIFIC)

Various options are provided as possible answers to the following questions. Choose the correct answer and write only the letter (A–D) next to the question number (4.1–4.14) in the ANSWER BOOK, for example 4.15 A.

4.1 Identify the equipment shown below.

- Compression tester

- Cylinder leakage tester

- Gas analyser

- Battery charger (1)

4.2 Which ONE of the following types of equipment is used to test the rate of leakage in the cylinders of an internal combustion engine?

- Spring tester

- Pressure tester

- Tensile tester

- Cylinder leakage tester (1)

4.3 The most commonly used firing order of a four-cylinder in-line engine is …

- 1,3,4,2 OR 1,2,4,3.

- 3,2,4,1 OR r 1,2,3,4.

- 2,3,4,1 OR 1,4,3,2.

- 3,4,1,2 OR 1,2,4,3. (1)

4.4 Which ONE of the following is responsible for an engine vibration and a weak power output of an SI engine?

- Too much oil in the engine sump

- Valves not properly closed or worn out

- Inefficient cooling system

- Bad oil filter (1)

4.5 Which of the following criteria does not suit a good injector?

- Precise fuel flow rate

- Good spray characteristics

- Low noise

- Fuel leakage (1)

4.6 The low oil pressure warning light turns on when the oil pressure in the engine galleries is too low. The following factors are the possible causes of this problem.

Choose the ONE that is not a possible cause.

- Worn oil pump

- Blocked oil pump pick-up screen in the sump

- Too much oil in the sump

- Blocked or restricted oil filter (1)

4.7 Calculate the torque applied to lock a bolt on a cylinder head using a torque wrench with a length of 500 mm when a force of 380 N is applied.

- 190 000 Nm

- 190 Nm

- 1,32 Nm

- 132 Nm (1)

4.8 Which ONE of the following safety precautions must be adhered to when you use a compression tester?

- Disconnect power to the ignition system

- Leave the throttle valve closed

- Connect the ignition system before testing

- Disconnect the cables without identification or labelling (1)

4.9 An engine has a combustion chamber volume of 54 cm3 and a compression ratio of 12 : 1. Calculate the swept volume.

- 594 cm3

- 295 cm3

- 495 cm3

- 54 cm3 (1)

4.10 Which ONE of the following options is a function of an optical alignment tool?

- It is used to read kingpin inclination

- It is used to determine the correct castor

- It is used to check the toe-in and toe-out of a vehicle

- It used to carry out dynamic wheel balancing (1)

4.11 Which term describes the condition when the driver of a turbo charged vehicle felt a delay between pressing the accelerator pedal and feeling the kick-in?

- Torque speed

- Lag

- Boost

- Stall speed (1)

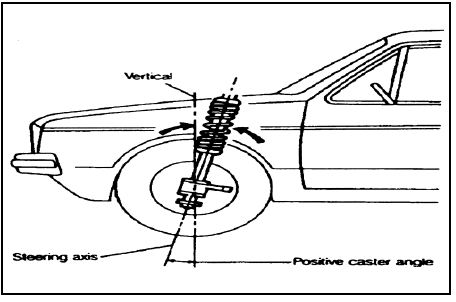

4.12 What type of alignment is displayed below?

- Positive castor

- Negative castor

- Positive chamber

- Negative chamber (1)

4.13 An epicyclic gear system consists of a central gear generally known as …

- planet gear.

- ring gear.

- pinion gear.

- sun gear. (1)

4.14 Which ONE of the following is the purpose of an oil pump in a three-speed automatic gearbox?

- To control the break band and the multi-disc clutches

- To regulate the speed of the sun gear

- To activate the smooth transfer of power

- To drive the plates of both clutches to rotate with the turbine (1)

[14]

QUESTION 5: TOOLS AND EQUIPMENT (SPECIFIC)

5.1 Name TWO functions of a diagnostic scanner. (2)

5.2 Explain how to couple up a diagnostic scanner on an engine. (3)

5.3 What is the main purpose of the following wheel alignment equipment?

5.3.1 Bubble gauge (2)

5.3.2 Turntable (2)

5.4 State THREE disadvantages of car wheels with incorrect alignment settings. (3)

5.5 Explain the set-up procedure for static balancing of wheel and tyre assembly. (3)

5.6 Give TWO reasons why you must carry out wheel balancing. (2)

5.7 Explain how to set up and take readings with a bubble gauge for camber angles. (5)

5.8 What is the advantage of using card-type compression meter? (1)

[23]

QUESTION 6: ENGINES (SPECIFIC)

6.1 State TWO functions of a crankshaft in an engine. (2)

6.2 A crankshaft is subject to vibrations as the engine is running or idling. Give TWO reasons responsible for these vibrations. (2)

6.3 What is the cause of the twisting effect on the crank shaft? (2)

6.4 Give FOUR built-in features applicable in improving engine balance. (4)

6.5 Define static balancing of a crankshaft. (2)

6.6 Identify THREE areas on a crankshaft where the balance mass piece can be fitted or removed in order to be perfectly balanced. (3)

6.7 Name TWO factors that determine the firing order of an engine. (2)

6.8 Briefly explain THREE possible ways you can use to determine the firing order of a vehicle engine. (3)

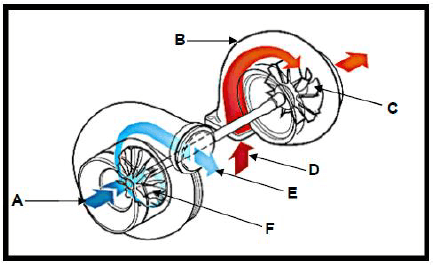

6.9 FIGURE 6.9 shows a turbocharger. Answer the questions that follow.

6.9.1 Label the parts A–F. (6)

6.9.2 What is the function of part C? (1)

6.9.3 What is the function of part F? (1)

[28]

QUESTION 7: FORCES (SPECIFIC)

7.1 Briefly explain the following terms in the cylinder of an internal combustion engine.

7.1.1 Swept volume (1)

7.1.2 Clearance volume (1)

7.1.3 Compression ratio (1)

7.1.4 Mechanical efficiency (1)

7.2 Briefly explain any FOUR methods used in raising the compression ratio of an engine. (4)

7.3 Calculate the compression ratio of an engine with a bore of 90 mm and a stroke of 86 mm if the combustion chamber volume is 61 cm3.. (6)

7.4 If the compression ratio gotten from QUESTION 7.3 above is increased with 30% by increasing the bore only, what will be the new diameter of the bore?

(4)

7.5 The following data was recorded during a test carried out on a four-stroke, four-cylinder petrol engine:

Mean effective pressure on the piston: 1400 kPa

Length of stroke: 78 mm

Cylinder bore: 98

Revolutions per minute: 4800 rpm

Torque: 280 Nm @ 3800 rpm

Number of cylinders: 4

Calculate the following:

7.5.1 Indicated power in kW (8)

7.5.2 The brake power in kW (4)

7.5.3 Mechanical efficiency (2)

[32]

QUESTION 8: MAINTENANCE (SPECIFIC)

8.1 State FOUR different types of gases coming out of the exhaust system that are analysed. (4)

8.2 Give THREE possible causes of high carbon monoxide (CO) readings from the exhaust of an internal combustion engine. (3)

8.3 Briefly explain THREE corrective measures that need to be followed when there are high oxygen readings from an exhaust system. (3)

8.4 After a cylinder leakage test has been conducted on an internal combustion engine, the results indicated high percentage leakage in the cylinders. Three possible faults were detected. State the faults in each of the following cases.

8.4.1 Hissing sound from the inlet manifold (1)

8.4.2 Hissing sound from the exhaust manifold (1)

8.4.3 Hissing sound from the dipstick (1)

8.5 Name THREE manufacturer’s specifications that are needed when doing a fuel pressure test. (3)

8.6 Briefly explain FOUR possible causes of low fuel pressure readings. (4)

8.7 Why must cooling system pressure testing be done? (1)

8.8 List TWO possible components in a cooling system where coolant could leak from during pressure testing. (2)

[23]

QUESTION 9: SYSTEMS AND CONTROL (AUTOMATIC GEARBOX) (SPECIFIC)

9.1 State TWO functions of an automatic transmission gearbox. (2)

9.2 Give THREE disadvantages of automatic transmission. (3)

9.3 Explain the operation of the double epicyclic gear train in low gear. (4)

9.4 Name THREE main components of the torque converter. (3)

9.5 Give TWO methods of cooling the oil in an automatic transmission. (2)

9.6 Give FOUR advantages of transmission control units in automatic-transmission drive. (4)

[18]

QUESTION 10: SYSTEMS AND CONTROL (AXLES, STEERING GEOMETRY AND ELECTRONICS) (SPECIFIC)

10.1 What is the function of a steering mechanism? (2)

10.2 State FOUR properties that a good steering mechanism must have. (4)

10.3 Use a neat sketch to explain the difference between positive and negative camber. (4)

10.4 Give THREE advantages of positive camber alignment. (3)

10.5 Briefly explain the purpose of the following alignment incorporation:

10.5.1 King pin inclination (2)

10.5.2 Ackermann principle (2)

10.6 Pre-check on a wheel must be carried out before balancing can be done. Give any THREE possible conditions that are expected to be checked. (3)

10.7 What is the purpose of a catalytic converter? (1)

10.8 Give THREE requirements for a catalytic converter to function effectively. (3)

10.9 Briefly explain the function of the following air-induction electronic components:

10.9.1 Manifold absolute pressure (MAP) sensor (2)

10.9.2 Idle speed control (ISC) valve (2)

10.9.3 Throttle position sensor (TPS) (2)

10.9.4 Mass air flow (MAF) meter (2)

[32]

TOTAL: 200

FORMULA SHEET FOR MECHANICAL TECHNOLOGY (AUTOMOTIVE)

Force = m x a

where m = mass

a = acceleration

Work = force x distance( F x d)

Power = force x distance

time

Torque = force x radius

Indicated power = P x L x A x N x n

where P mean effective pressure

L length of stroke

A area of piston crown

N number of power strokes per second

n number of cylinders

Brake power = 2 x π x N x T

where N = revolutions per second

T = torque

Brake power (P rony brake) F x 2 x π x R x N

where F force

R length of brake arm

N revolutions per second

Mechanical efficiency = brake power x 100

indicated power

Compression ratio= swept volume + clearance volume

clearance volume

where swept volume = π x D2 L

4

where L length of stroke

D = diameter of bore

Clearance volume = π x D2 x I

4

where D = diameter of bore

l = clearance

Gear ratio= product of the number of teeth of the driven gears

product of the number of teeth of the driver gears