FITTING AND MACHINING GRADE 11 PAT TASK 2021

Share via Whatsapp Join our WhatsApp Group Join our Telegram GroupMECHANICAL TECHNOLOGY

FITTING AND MACHINING

GRADE 11

PRACTICAL ASSESSMENT TASKS

2021

TABLE OF CONTENTS

SECTION A: (Educator Information)

- Background

- The structure of the PAT

- Administration of the PAT

- Assessment and moderation of the PAT

4.1 Assessment

4.2 Moderation

SECTION B: (The Learner task: Practical Assessment Task-PAT)

Phase 1

Phase 2

Phase 3

Phase 4

ANNEXURES:

Annexure A: Tolerances

Annexure B: Declaration of Authenticity – to be completed by Learner and Educator.

SECTION A: EDUCATOR GUIDELINES FOR PAT GRADE 111.

- Background

The 17 National Curriculum Statement subjects which contain a practical componentall include a Practical Assessment Task (PAT), i.e. a Practical or Performance Assessment Task. These subjects are:

AGRICULTURE: Agricultural Management Sciences, Agricultural Technology

ARTS: Dance Studies, Design, Dramatic Arts, Music, Visual Arts

HSS: Life OrientationSCIENCES: Computer Applications Technology, Information Technology

SERVICES: Consumer Studies, Hospitality Studies, Tourism

TECHNOLOGY: Civil Technology, Electrical Technology, Engineering Graphics and Design, MECHANICAL TECHNOLOGY

A PAT allows the Educator to directly and systematically observe applied competence. The PAT comprises the application/ performance of the knowledge,skills and values particular to that subject and counts 25% (i.e. 100 marks) of the total promotion/ certification mark out of 400 for the subject. In the two Arts subjects Design and Visual Arts, the PAT counts 37.5% (i.e. 150 marks) of the total promotion/ certification mark out of 400 for the subject.

The PAT is implemented across the first three terms of the school year andshould be undertaken as one extended task, which is broken down into differentphases or a series of smaller activities that make up the promotion PAT mark. The planning and execution of the PAT differs from subject to subject.

Section A are guidelines to Educators, Section B should be given to Learners at the beginning of the year.

Any profession requires of its members a thorough grounding in both practice andtheory, and MECHANICAL TECHNOLOGY is no exception. It is emphasized that the goal of the Practical Assessment Task is not to produce a skilled craftspersonbut a Mechanical Technology Learner in the broadest sense. A nation’s true wealthis in its human potential / resource and education should aim to develop the talentsof Learners so that they can contribute to the well-being of society by using scientificand technological resources with the greatest efficiency and by continuing to develop them.

To prepare a Learner in MECHANICAL TECHNOLOGY for one or more of these activities his/ her education should develop in him/ her:

A mentality which can selectively assimilate ideas, evidence and facts, and by drawing logical conclusions put them to good use creatively and with imagination;A capability to express ideas and information clearly by speech, writing, sketching orformal drawing by hand or computer package;

A willingness and capability to accept and exercise responsibility, to make decisions,and to learn by experience.

Attributes such as these cannot all be achieved in a classroom. A sound knowledgeof applicable technical science and maths is essential to the MECHANICALTECHNOLOGY Learner, so also is the close practical acquaintance with theprocesses. There is no substitute for acquiring the “feel” of things on the shop floor,where training in the art of making things, the essential bridge between theory andpractice, can be so readily obtained.

Practical application in the workshop must therefore be made an interesting andchallenging experience, mentally and physically, with encouragement to the Learnerto use their initiative, curiosity and persistence in finding things out for themselves.Learning by watching should be kept to the bare minimum. Enabling the Learner withsome degree of responsibility during practical application is very important as astimulus and to develop self-confidence.

PAT tasks must not be confused with the practical application of the subject during workshop practice sessions that is assessed informally. These artefacts are to bekept as proof of progress – Learners names / form of identification must be clearlyattached to these artefacts. - The structure of the PAT for Mechanical Technology

The Practical Assessment Task is designed and developed for a Learner to use anddemonstrate the various skills they acquired during workshop practice to manufacture a project of a high quality. The PAT is made up of an integration (or acombination) of various topics as is found in the CAPS document. Safety and tools will always form an integral part of the PAT’s.

Take Note: The Technological Process per se, which was covered in detail, in the GET Phase, does not form part of the Practical Assessment Task in the FET Phase– Yet the concepts and methods form the foundation in the planning and execution of all tasks and processes. The focus and emphasis now, will be on a Learner's ability to read and follow instructions in order to produce accurate quality projects.Each Learner must complete the four phases of the PAT under controlled conditionsand under the supervision of the teacher. No group work is allowed.

The Practical Assessment Task consists of FOUR phases that the Learner mustcomplete as set out in the table on the next page. Phase four will be a combinationof skills that have been shown in phases one to three.

Educators must attend to the following in their preparation:STRUCTURE OF THE PAT PROCESS OF THE PAT TOPIC MARKS TERM 1 Phase 1 Task Terminology / Outside Taper Turning 50 Phase 4 Task Teacher to Prepare (material and equipment) TERM 2 Phase 2 Task Terminology / Inside Taper Turning 50 Phase 4 Task Under construction TERM 3 Phase 3 Task Terminology / Manufacturing 50 Phase 4 Task Terminology / Lathe machines / Complete Task 100 TOTAL MARKS Convert to 100

The planning process;

The knowledge and skills to be achieved;

The safety and environmental aspects to be considered;

The applicable calculations, sketches and/ or diagrams;

The starting time and ending time – how long it took to complete from start to finish;

Bill of materials;

List of tools needed; and

Any other information that is relevant to the project. - Administration of the PAT

The PAT (all phases) should be completed in the first three terms. The PAT mustbe completed under controlled conditions.

Educators must attach their own due dates for the different phases of the PAT(Refer: Mechanical Technology CAPS Gr10 – 12 Document.

In this manner, Learners can easily assess their progress. Instances where formal assessments take place, it is the responsibility of the Educator to administer the assessment.

Educators are requested to make copies of Section B and distribute to Learners atthe beginning of the year. Learners should receive the assessment criteria of the PAT at the beginning of the year when the PAT is handed out and this must bemediated with the Learners. - Assessment and moderation of the Practical Assessment Task

To ensure national standardization the PAT’s for Grade 12 are externally set andmoderated, but internally assessed. The PAT’s for Grade 10 and 11 have to follow asimilar standardization process but this is done provincially and thus are set byallocated people and moderated by the Subject Advisers for Mechanical Technology.

4.1 Assessment

Frequent developmental feedback by the Educator is needed to guide and givesupport to the Learner to ensure that the Learner is progressing as envisaged.

Both formal and informal assessment should be conducted on the different phasesthat constitute the PAT. Informal assessment can be conducted by the Learnersthemselves, by a peer group of Learners, or by the Educator. Formal assessment should always be conducted by the Educator and must be recorded on the working mark sheets distributed by the Subject Advisers, these also constitute the final marksheet for the subject and must always be available in printed format in the EducatorsFile. These mark sheets must be updated and printed after each formal assessment.Note that the School and District structures may require results to be transferred toother documents/ systems like SASAMS, in this instance ALL results must correspond on all systems. Any differences must be brought to the attention of theSubject Advisor so that the error can be rectified.

4.2 Moderation

During moderation of the PAT, the project/ skills tasks will be presented to themoderator with the assessment criteria and marks obtained on the facets mark sheet and the combined Excel working mark sheet.

Where required, the moderator should be able to call on the Learner to explain thefunction, principles of operation and also request the Learner to exhibit the skills acquired through the capability tasks for moderation purposes.

4.3 Time planning:

Phase 1: Complete at the end of first term – April.

Phase 2: Complete at the end of second term – July.

Phase 3: Complete during third term - End of September.

Phase 4: Plan and start task during the first term and completeat the end of September.

SECTION B: THE PRACTICAL ASSESSMENT TASK GRADE 11

FITTING AND MACHINING

The Practical Assessment Task (PAT) consists of FOUR Phases, one per term over term 1to 3, with the Phase 4 Task to be started in the First Term and completed in the Third Term – Thus spanning all three terms. Term 4 is reserved for the final theoretical contentand revision.

NO PAT’s are planned or to be completed in in the fourth term! PAT’s will only beallowed to be completed in exceptional situations.

Terminology - Turning Task

Procedure:

The following task is to let the learners get to know how to work with the lathe machine.

Choice of material to be used is Aluminium or Nylon / Teflon.

READ ALL THE INSTRUCTIONS FIRST - THEN PROCEED

FOLLOW ASSESSMENT INSTRUCTIONS - AS INDICATED

Resources Required:

- Aluminium or steel Ø50mm rough cut at 150mm long

- Centre lathe with related attachments and tools.

- Lathe cutting tools for facing, parallel turning, taper cutting and parting off

- Vernier and other measuring equipment (callipers, steel rule etc).

- Marking medium (Engineers blue, Koki pen, chalk etc.)

- Marking off instruments (Square, scriber etc.)

- Appropriate Personal Protection Equipment (PPE).

Activity Outcome

- Learners familiarize themselves with the use of tools and machines.

- Learners apply theoretical and practical knowledge in which they obtained during Grade 10practical.

Requirements:/Tools:

- Lathe machine

- Tool bit holder and key

- Tool facing and cutting parallel surfaces

- Chuck and Tailstock centre

- Two tool bits

- Vernier calliper

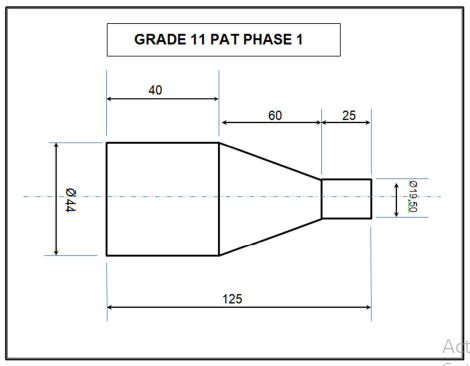

Fitting and Machining – Phase 1 PAT Task

Method

- Material needed: 150 – 200mm aluminium bar (steel may also be used)

- Face both ends and centre drill each end

- Reduce diameter to 44mm

- From one end – reduce diameter for a length of 25mm to 19,50mm

- Calculate the degrees that the compound slide must be set to in order to cut the taper of a length of 60mm where the big diameter is 44mm and the small diameter is19,50mm. (If the measurements are out, the learner must use his own measurementto calculate the taper in order for the taper to be still correct)

- From the end of the taper, measure a length of 40mm and part the project. The totallength must come then to a measurement of 125mm.

Marking Rubric – PAT Task 1 - Phase 1 – External Taper

| GRADE: 11 | YEAR: 2021 | SCHOOL: | |||||||||||

| DATE STARTED: | DATE COMPLETED: | ||||||||||||

| FITTING AND MACHINING | EDUCATOR: | ||||||||||||

| PROJECT: PAT TASK 1 | NUMBER OF LEARNERS: | ||||||||||||

| Page 1 of 1 | |||||||||||||

| Turning Task | |||||||||||||

| NAMES OFLEARNERS | Facing | Parallel & TaperTurning | Length | TOTAL | |||||||||

| FACETS | Facing x 2 sides | Drilling centre holes x 2 | Ø 44 mm | Ø 19,50mm | Taper Calculations | Cutting of taper | 25mm Length (Ø 19,50) | 60mm Length (Taper) | 40mm Length (Ø 44) | Finishing | -1 For every day late | ||

| Marks | 4 | 4 | 6 | 6 | 6 | 5 | 5 | 5 | 5 | 4 | -1 | 50 | |

| 1 | |||||||||||||

| 2 | |||||||||||||

| 3 | |||||||||||||

| 4 | |||||||||||||

| 5 | |||||||||||||

| 6 | |||||||||||||

| 7 | |||||||||||||

| 8 | |||||||||||||

| 9 | |||||||||||||

| 10 | |||||||||||||

| 11 | |||||||||||||

| 12 | |||||||||||||

| 13 | |||||||||||||

| 14 | |||||||||||||

| 15 | |||||||||||||

| 16 | |||||||||||||

| 17 | |||||||||||||

| 18 | |||||||||||||

| SIGNATURE OF EDUCATOR: | Date: | ||||||||||||

| SIGNATURE OF HEAD OF DEPARTMENT: | Date: | ||||||||||||

| SIGNATURE OF PRINCIPAL: | Date: | ||||||||||||

| SIGNATURE OF SUBJECT ADVISOR: | Date: | ||||||||||||

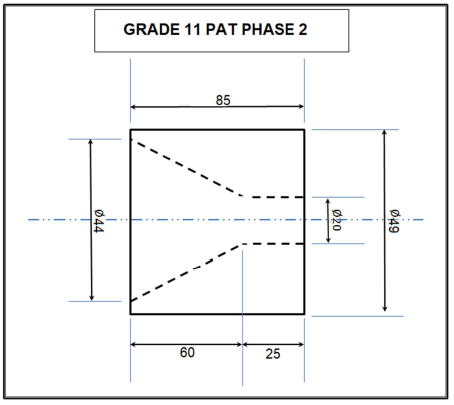

Fitting and Machining – Phase 2 PAT Task – Internal Taper

Method:

- Material needed: 100 – 150mm aluminium bar (steel may also be used)

- Face both ends and centre drill each end

- Reduce diameter to 49mm

- Drill a 15mm centre hole in the work piece and then bore to a size of 20mm (Itmust be deep enough when parting is done, the end is open)

- Calculate to what degree the compound slide must be set to in order to cut the internal taper

- Use the appropriate boring bar to cut the taper.

- The taper must be at the big end 44mm in diameter and a length of 60 mm.

- When the cutting procedure is completed, the PAT Task from Term 1 must beable to fit neatly in this internal taper.

Marking Rubric – PAT Task Phase 2 -Term 2 – Internal Taper

| GRADE: 11 | YEAR: 2021 | SCHOOL: | |||||||||||

| DATE STARTED: | DATE COMPLETED: | ||||||||||||

| FITTING AND MACHINING | EDUCATOR: | ||||||||||||

| PROJECT: PAT TASK 2 | NUMBER OF LEARNERS: | ||||||||||||

| Page 1 of 1 | |||||||||||||

| Turning Task | |||||||||||||

| NAMES OFLEARNERS | Facing | Parallel & TaperTurning | Length | TOTAL | |||||||||

| FACETS | Facing x 2 sides | Drilling centre holes x 2 | Ø 49 mm | Ø20mm Hole bored | Taper Calculations | Cutting of taper | 85mm Length | 60mm Length (Taper) | 25mm Length (Ø 20 Hole) | Finishing | -1 For every day late | ||

| Marks | 4 | 4 | 6 | 6 | 6 | 5 | 5 | 5 | 5 | 4 | -1 | 50 | |

| 1 | |||||||||||||

| 2 | |||||||||||||

| 3 | |||||||||||||

| 4 | |||||||||||||

| 5 | |||||||||||||

| 6 | |||||||||||||

| 7 | |||||||||||||

| 8 | |||||||||||||

| 9 | |||||||||||||

| 10 | |||||||||||||

| 11 | |||||||||||||

| 12 | |||||||||||||

| 13 | |||||||||||||

| 14 | |||||||||||||

| 15 | |||||||||||||

| 16 | |||||||||||||

| 17 | |||||||||||||

| 18 | |||||||||||||

| 19 | |||||||||||||

| SIGNATURE OF EDUCATOR: | Date: | ||||||||||||

| SIGNATURE OF HEAD OF DEPARTMENT: | Date: | ||||||||||||

| SIGNATURE OF PRINCIPAL: | Date: | ||||||||||||

| SIGNATURE OF SUBJECT ADVISOR: | Date: | ||||||||||||

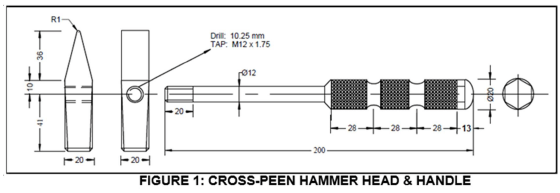

Fitting and Machining – Phase 3 & 4 PAT Task – Cross Peen Hammer

The Hammer head is manufactured during Phase 3. The hammer handle is done during phase 4 because of the availability of machinery. For example, there may be too few lathes for the number of learners. It gives the learners the opportunity to work on the machinery throughout the year.

PHASE 3 – HAMMER HEAD

Phase 3: Specifications

| ITEM NO | DESCRIPTION | MATERIAL | SIZE | QUANTITY |

| 1 | Cross-peen hammer head | Any of the following:

| 20 x 20 x90 mm | 1 |

Phase 3: Processes

- File the sides square and mark off the hole and the sides.

- Drill the 10,25 mm hole and tap to M12 x 1,75.

- Mill the cross-peen sides of the head.

- File the cross peen and polish.

Phase 3: Time frame

- Commencement date: July 2021

- Completion date: September 2021

Phase 3: Assessment

Annexure

| FITTING AND MACHINING GRADE 11 | |||||||||||||||||||

| SUBJECT: FITTING AND MACHINING | SCHOOL: | ||||||||||||||||||

| YEAR: 2021 | TEACHER: | ||||||||||||||||||

| GR:11 | NUMBER OF LEARNERS: | ||||||||||||||||||

| DATE STARTED: | DATE COMPLETED: | ||||||||||||||||||

| PROJECT: PEEN HAMMER HEAD | PAGE: 1 OF | ||||||||||||||||||

| FACETS | Mark Allocation | Names of Learners | |||||||||||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | |||

| Mill one end andone side flat | Mill length of 87mm | 3 | |||||||||||||||||

| Mill to thickness of 20mm | 2 | ||||||||||||||||||

| Mark off the hole to be drilled and the profile of the cross peen According to drawing | Marking off hole position accurately according to drawing | 2 | |||||||||||||||||

| Center punch where hole is drilled | 2 | ||||||||||||||||||

| Mark off cross peen on all sides | 4 | ||||||||||||||||||

| Accuracy | 2 | ||||||||||||||||||

| Drill hole and tap to fit handle | Hole centred - 4mm from each side | 2 | |||||||||||||||||

| Drill with correct size drill | 2 | ||||||||||||||||||

| Hole 5mm from taper edge | 2 | ||||||||||||||||||

| Squareness to surface | 2 | ||||||||||||||||||

| Tap hole correctly without crossthread | 2 | ||||||||||||||||||

| Set-up in milling machine | Mount workpiece in machine vice | 2 | |||||||||||||||||

| Set to angle to be milled | 2 | ||||||||||||||||||

| Mill side 1 - 41mm | 3 | ||||||||||||||||||

| Mill side 2 - 41mm | 3 | ||||||||||||||||||

| Mill the cross peen | Accuracy of Milling | 3 | |||||||||||||||||

| Surface finish | 2 | ||||||||||||||||||

| Mark off and file the borrom and sides | Marking off according to drawing | 2 | |||||||||||||||||

| Filing bottom and sides and finish | 3 | ||||||||||||||||||

| Overall finishing | 5 | ||||||||||||||||||

| Time (-1 for every day late) | -1 | ||||||||||||||||||

| TOTAL | 50 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| SIGNATURE OF TEACHER | DATE | SIGNATURE OF PRINCIPAL | DATE: | ||||||||||||||||

| SIGNATURE OF HOD | DATE | SIGNATURE OF SENIOR EDUCATIONAL SPECIALIST: | DATE: | ||||||||||||||||

PHASE 3 – HAMMER HANDLE

Phase 4: Specification

| ITEM NO. | DESCRIPTION | MATERIAL | SIZE | QUANTITY |

| 1 | Cross-peenhammer handle | Any of the following:• Aluminium• Mild steel | Ø 20 x 200 mm | 1 |

Phase 4: Processes

- Face both ends of the shaft• Centre drill both ends

- Turn to required diameters

- Mill hexagon on one end

- Knurl, taper turn and cut threads according to drawing

Phase 4: Time frame

- Commencement date: January 2021

- Completion date: September 2021

Phase 4: Assessment

| CROSS-PEEN HAMMER HANDLE | |||||||||||||||||||||||||

| SUBJECT: FITTING AND MACHINING | SCHOOL: | ||||||||||||||||||||||||

| YEAR: 2021 | TEACHER: | ||||||||||||||||||||||||

| GR:11 | NUMBER OF LEARNERS: | ||||||||||||||||||||||||

| DATE STARTED: | DATE COMPLETED: | ||||||||||||||||||||||||

| PROJECT: PHASE 4 | PAGE: 1 | ||||||||||||||||||||||||

| FACETS | Mark Allocation | Names of Learners | |||||||||||||||||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | ||||

| Facing and centre drill | 5 | ||||||||||||||||||||||||

| Diameter turning Ø12mm | 7 | ||||||||||||||||||||||||

| Diameter turning Ø20mm | 7 | ||||||||||||||||||||||||

| Calculate thread depth - M12 x 1,75 | 5 | ||||||||||||||||||||||||

| Calculate indexing | 5 | ||||||||||||||||||||||||

| Cut M12 x 1,75 thread on centre lathe | Length of thread | 5 | |||||||||||||||||||||||

| Thread smoothness | 5 | ||||||||||||||||||||||||

| Thread depth measure correct | 5 | ||||||||||||||||||||||||

| Cut hexagon | Cutting depth correct | 7 | |||||||||||||||||||||||

| Flat side distance correct | 7 | ||||||||||||||||||||||||

| Distance across sides correct | 7 | ||||||||||||||||||||||||

| Knurl handle neatly (deep enough and not smooth ) | 5 | ||||||||||||||||||||||||

| Cut grooves (Same depth and groove distance ) | 4 | ||||||||||||||||||||||||

| Chamfering (Front of knurl / back -3mm each ) | 4 | ||||||||||||||||||||||||

| Handle length - 100mm | 7 | ||||||||||||||||||||||||

| Total length - 200mm | 7 | ||||||||||||||||||||||||

| Assembly (Handle fit proper and square) | 3 | ||||||||||||||||||||||||

| Time (-1 for every day late) | -1 | ||||||||||||||||||||||||

| TOTAL | 100 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | ||

| SIGNATURE OF TEACHER: | DATE | SIGNATURE OFPRINCIPAL: | DATE | ||||||||||||||||||||||

| SIGNATURE OF HOD: | DATE | SIGNATURE OF SENIOREDUCATIONALSPECIALIST: | DATE | ||||||||||||||||||||||

ABSENCE/NON-SUBMISSION OF TASKS

If a learner's practical assessment task is incomplete or unavailable for avalid reason, the learner will be given three weeks before the commencement of the final end-of-year examinations to submit the outstanding task. Should a learner fail to fulfil the outstanding PAT requirement such a learner will be awarded a zero (0) for that PATcomponent.

A learner's results are regarded as incomplete if he/she does not offer anycomponent of the PAT task. He/She will be given another opportunitybased on the decision of the Head of the Assessment Body.

Should the learner fail to fulfil the outstanding PAT requirement, themarks for these components will be omitted and the final mark for Mechanical Technology will be adjusted for promotion purposes in terms ofthe completed tasks.

TIME FRAMES

January:

Phase 1:Manufacturing external taper

Phase 4:Although Phase 3 task the hammer head forms partof the Phase 4 PAT, it will only be assessed once, inTerm 3 for 50 marks.

April:

Phase 2:Manufacturing internal taper

Phase 4:Project under construction

July:

Phase 3:Manufacturing hammer head

Phase 4:Project under construction

September:

Phase 3/4:Complete the cross-peen hammer handle and head at the end of third term

ANNEXURE A

| TOLERANCE | Marks | TURNING | FILING | MILLING flat surfaces | |

| Diameter | Length | Measure 4 places | Measure 4 places | ||

| + 0.8 | + 0.8 | + 0.8 | + 0.8 | ||

| - 0.8 | - 0.8 | - 0.8 | - 0.8 | ||

| DEVIATION | 7 | 0,10 = 100% | 0,1 = 100% | 0,10 = 100% | 0,1 = 100% |

| 6 | 0,15 = 85% | 0,2 = 85% | 0,15 = 85% | 0,2 = 85% | |

| 5 | 0,20 = 70% | 0,3 = 70% | 0,20 = 70% | 0,3 = 70% | |

| 4 | 0,25 = 60% | 0,4 = 60% | 0,25 = 60% | 0,4 = 60% | |

| 3 | 0,30 = 40% | 0,5 = 40% | 0,30 = 40% | 0,5 = 40% | |

| 2 | 0,35 = 25% | 0,6 = 25% | 0,35 = 25% | 0,6 = 25% | |

| 1 | 0,40 = 10% | 0,7 = 10% | 0,40 = 10% | 0,7 = 10% | |

GRADE 11

PRACTICAL ASSESSMENT TASKS

PHASES ONE, TWO, THREE and FOUR

ANNEXURE B

DECLARATION OF AUTHENTICITY

NAME OF THE SCHOOL: …………………………………………………….

NAME OF LEARNER: ………………………………………………………...

(FULL NAME(S) AND SURNAME)

EXAMINATION NUMBER: ………………………………………………….

NAME OF TEACHER: ……………………………………………………….

SCHOOL STAMP

|

I hereby declare that the project submitted for assessment is my own, original work and has not been previously submitted for moderation.

___________________________________ ________________

SIGNATURE OF CANDIDATE DATE

As far as I know, the above declaration by the candidate is true and I accept that thework offered is his or her own.

___________________________________ ________________

SIGNATURE OF TEACHER DATE