MECHANICAL TECHNOLOGY AUTOMOTIVE PAT TASK GRADE 11 2021

Share via Whatsapp Join our WhatsApp Group Join our Telegram GroupMECHANICAL TECHNOLOGY

PRACTICAL ASSESSMENT TASK

AUTOMOTIVE

GRADE 11

2021

TABLE OF CONTENTS

| Page | |

| 1. INTRODUCTION/BACKGROUND | 3 – 4 |

| 2. TEACHER GUIDELINES 2.1 Administration of PAT 2.2 Assessment of PAT 2.3 Moderation of PAT 2.4 Consequences of absence/non-submission of tasks 2.5 Time management 2.5 Declaration of authenticity 6 | 4 4 4 5 5 5 6 |

| 3. LEARNER GUIDELINES 3.1 Instructions to the learner 7 | 7 7 |

| 4. SPECIALISATION - SECTION B: AUTOMOTIVE | 8 8-18 |

- INTRODUCTION/BACKGROUND

The 16 Curriculum and Assessment Policy Statements subjects which contain a practical component all include a Practical Assessment Task (PAT), i.e. a Practical or Performance Assessment Task. These subjects are:- AGRICULTURE: Agricultural Management Practices, Agricultural Technology

- ARTS: Dance Studies, Design, Dramatic Arts, Music, Visual Arts

- SCIENCES: Computer Applications Technology, Information Technology

- SERVICES: Consumer Studies, Hospitality Studies, Tourism

- TECHNOLOGY: Civil Technology, Electrical Technology, MECHANICAL

TECHNOLOGY and Engineering Graphics and Design.A PAT allows the educator to directly and systematically observe applied competence. The PAT comprises the application/performance of the knowledge, skills and values particular to that subject and counts 25% (i.e. 100 marks) of the total promotion/certification mark out of 400 for the subject.

The PAT is implemented across the first three terms of the school year, which is broken down into different practical skills that make up the PAT.

Any profession requires of its members a thorough grounding in both theory and practice, and MECHANICAL TECHNOLOGY is no exception. It is emphasized that the goal of the Practical Assessment Task is to produce a skilled learner in each specialisation field. A nation's true wealth is in its manpower and education should aim to develop the talents of the learner so that he/she can contribute to the wellbeing of society by using scientific and technological resources with the greatest efficiency and by continuing to develop them.

To prepare a learner to develop skills in MECHANICAL TECHNOLOGY, in each specialisation field:- An attitude where the learner can selectively assimilate ideas, gather evidence and facts, and drawing logical conclusions and put them to good use creatively and with imagination;

- A capability to express ideas and information clearly by speech, writing, sketching or drawing;

- A willingness and capability to accept and exercise responsibility, to make decisions, and to learn by experience.

Attributes such as these cannot all be achieved in a classroom. A sound knowledge of engineering science is essential to equip the MECHANICAL TECHNOLOGY learner with the necessary practical capabilities for the required processes. Training is the art of acquiring essential skills to bridge between trade theory and practice.

Practical application in the workshop must therefore be made an interesting and challenging experience, mentally and physically, with encouragement to the learner to use his/her initiative, curiosity and persistence in finding things. The giving of some degree of responsibility during practical application is very important as a stimulus and to develop self-confidence.

- TEACHER GUIDELINES

2.1 Administration of the PAT

Teachers are requested to make copies of the different assessment criteria of the PAT document. These documents need to be distributed to the learners at the beginning of each phase of PAT to be completed. The Practical Assessment Task for Grade 11 is internally set and moderated.

Teachers must attach due dates for the different terms of the PAT task (refer to the CAPS document). In this manner, learners can easily assess their progress.

Instances where formal assessments take place, it is the responsibility of the teacher to administer assessment.

The PAT should be completed in the first three terms. The PAT should be based and completed under controlled conditions (Refer to the Mechanical Technology CAPS Grade 10–12).

Teachers must ensure that each learner has a portfolio of evidence and that it is kept in a safe place.

The must be available at all times when requested for by a department official for scrutiny or moderation.

2.2 Assessment of PAT

Frequent and developmental feedback is needed to guide and give support to the learner to ensure that the learner is on the right track.

Both formal and informal assessment should be conducted in different terms to ensure that the embedded skills are covered for the PAT. Informal assessment can be conducted only to monitor progress of the term in which the learners are engaged. Formal assessment should always be conducted by the teacher and will be recorded.

2.3 Moderation of PAT

During moderation of the PAT, the term tasks will be presented to the moderator with the assessment criteria and marks obtained.

Where required the moderator should be able to call on the learner to explain the function, principles of operation and also request the learner to demonstrate the skills acquired through the capability tasks for moderation purposes.

Upon completion the moderator will, if necessary, adjust the marks of the group up or downwards depending on the decision reached as a result of moderation.

2.4 CONSEQUENCES OF ABSENCE/NON SUBMISSION OF TASKS.

If a learners’ Practical Assessment Task is incomplete or unavailable with valid reason, the learner will be given three weeks before the commencement of the final end-of-year examination to submit outstanding task. Should the learner fail to fulfill the outstanding PAT requirement, such a learner will be awarded a zero for that PAT component.

A learner's results are regarded as incomplete if he/she does not offer any component of the PAT task. He/she will be given another opportunity based on the decision of the Head of the assessment body.

Should the learner fail to fulfill the outstanding PAT requirement, the marks for these components will be omitted and the final mark for Mechanical Technology will be adjusted for promotion purposes in terms of the completed

2.5 Management Plan:

Phase 1: Complete at the end of first term – April.

Phase 2: Complete at the end of second term – July.

Phase 3: Complete during third term - End of September.

Phase 4: Plan and start task during term one and complete at the end of

September (third term).

2.6 DECLARATION OF AUTHENTICITY

NAME OF THE SCHOOL: ………………………………………………………..

NAME OF LEARNER: …………………………………………..………………...

(FULL NAME(S) AND SURNAME)

EXAMINATION NUMBER: ……….……………………………………………….

NAME OF TEACHER: …………………………………………………………….

I hereby declare that the project submitted for assessment is my own, original work and has not been previously submitted for moderation.SCHOOL STAMP

Any theoretical questions in the practical task were done under exam conditions and assessed by the teacher. Answers were not copied from the text books.

________________________ ____________

SIGNATURE OF CANDIDATE DATE

As far as I know, the above declaration by the candidate is true and I accept that the work offered is his or her own.

Each learner was tested individually on the tasks he/she performed individually under my supervision and marked/assessed whiles he/she performed the task under exam conditions.

___________________________________ ____________

SIGNATURE OF TEACHER DATE - LEARNER GUIDELINES

3.1 Instructions to the learners

- The Practical Assessment Task (PAT) consists of specialisation task in Automotive. The practical work is spread over three terms as set out in each of the specialisation areas.

- All tasks must be completed according to the time frames set out in each of the tasks.

- Learners are required to actively engage in all practical assessment tasks.

- Learners who are un-cooperative will receive demerits or a zero mark allocation for that particular section of the work.

- Learners, who act unsafely in the workshop and place other learners in danger, will be removed from the workshop and given additional corrective tasks to improve their safety awareness.

- ALL PRACTICAL TASKS MUST BE DONE ON ACTUAL ENGINES OR COMPONENTS AS SUPPLIED BY THE TEACHER TO YOU (EXCEPT FOR THE RESEARCH TASKS).

- LEARNERS TO COMPLETE THE PHASES OF EACH PAT AFTER HE/SHE HAD TIME TO EXPLORE AND PRACTICE THE TASK. ONLY THEN THE TASK IS TO BE COMPLETED UNDER THE SUPERVISION OF THE TEACHER

- WORKSHEETS OR ANY WRITTEN WORK DONE BY YOU MUST BE KEPT IN AN PORTFOLIO FILE AS EVIDENCE

SECTION B: THE PRACTICAL ASSESSMENT TASK GRADE 11

The Practical Assessment Task (PAT) consists of FOUR Phases, one per term over term 1 to 3, with the Phase 4 Task that can be started in the First Term and completed in the Third Term – Thus spanning all three terms. Term 4 is reserved for the final theoretical content and revision.

NO PAT’s in fourth term!

AUTOMOTIVE

Engines - Valves

Term: 1 (Phase 1)

Start date: January 2021

Completion date: April 2021

Mark allocation: 50

Duration of assessment: 12 hours

PRACTICAL LEARNER ASSESSMENT WORKSHEET: VALVES AND VALVE TIMING

Name:_____________________ Class:___________

Valves:

1.1 State ONE type of engine valve and its function

| 1 | Type: | (1) |

| 2. | Function: | (1) |

1.2 Identify TWO different types of overhead valve arrangements in your workshop. Complete the table after you identified them.

| Name Type | Sketch/diagrams of valve arrangement – label sketch | |

| 1 | 3 | 1+3 (4) |

| Name Type | Sketch/diagrams of valve arrangement – label sketch | |

| 1 | 3 | 1+3 (4) |

2 Obtain specifications for the engine in the workshop you are going to use for the practical task below

Type of engine: _________________________________________

| 2.1 | Valve clearance setting if any. | (2) |

| Explain why there is no clearance setting | or (2) |

3 Torqueing of the cylinder head. Same engine as above:

| 3.1 | Specifications: | (2) |

| 3.2 | Make a neat sketch in opposite Colum to show the sequence used to torque cylinder head bolts | (2) |

Determine valve timing on same engine used to set valve clearance:

This section of the task may be done in a group of two. Each person will check each other for accuracy.

Each learner to create their own timing disc for marks.

Put your name on disc and hand to teacher to check and mark.

Valve clearances must be checked if necessary for accuracy.

THE TASK MUST BE DONE PRACTICALLY BY EACH LEARNER.

THEORETICALLY TASKS WILL NOT BE ACCEPTED

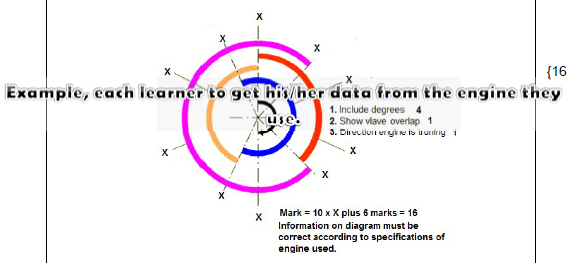

| 4.1 | Create a valve timing disc that will fit the front pulley of your engine. | (6) |

| Mark disc of in degrees from zero to 360º | (2) | |

| Attach disc to front pulley with Pritt or something similar. | (1) | |

| Line your zero mark to the TDC line. | (2) | |

| Specifications of the engine: | (1) | |

| 4.2 | Remove tappet cover/rocker cover. | (2) |

| 4.3 | Turn engine and use degrees on disc to determine the valve timing for the specific engine. Record the valve lead and valve lag. Compare to the specifications. Marks allocated on timing diagram according to accuracy to specifications and correctness. | |

| 4.4 | Draw a valve timing diagram to show the following:

| (16) |

| 4.4 | Explain the effect that incorrect valve clearance setting will have on your valve timing diagram | (2) |

| TOTAL | [50] |

Systems and Control – differential OR Systems and Control – hydraulic brakes

Teacher may choose one of the above two tasks for learners to complete for phase 2

Term: 2 (Phase 2)

Start date: April 2021

Completion date: July 2021

Mark allocation: 50

Duration of assessment: 12 hours

PRACTICAL LEARNER ASSESSMENT WORKSHEET: Choice 1 – Differential

Name:_____________________ Class:___________

Differential:

Type of differential used by each learner (give a short description)

Requirements:

- Transaxle transmissions

or

- Conventional differentials

or

- Limited slip differentials

- Hand tools

- Measuring equipment

- Consumables

Teacher:

- Teacher make available differentials to learners (After the component has been taught to the learners) – could be any of above mentioned or all three types whatever is available in your workshop.

- Teacher to facilitate dismantling of differentials

- Teacher to number any 10 components on the stripped differential with example masking tape and Koki pen.

- After practical task has been completed teacher facilitate assembling of differential.

- Teacher to mark this task while each learner is busy completing it.

Learner:

- Dismantle differential under teacher’s supervision. (5)

- Clean all differential components.

- Lay out all components in an exploded view on work bench.

- Identify the 10 numbered components and give the function of each. (20)

- Examine each component for wear and tear.

- Compile a condition report on the 10 numbered components. (10)

- Work out the gear ratio for the differential. Show your calculation. (4)

- Assemble the differential. (5)

- Explain the power flow on the assembled differential going around an imaginary corner. (Record and explain to teacher on the differential) (6)

- Learner to record dismantling and assembling steps and all relevant information.

Total = (50)

Hydraulic brakes:

PRACTICAL LEARNER ASSESSMENT WORKSHEET: Choice 2 – Hydraulic brakes.

Name:_____________________ Class:___________

Requirements:

Vacuum servo units and brake master cylinders

Hand tools

Measuring equipment

Consumables

Vacuum servo unit and master cylinder:

Teacher:

11. Teacher to make vacuum servo units and master cylinders available to learners.

12. Teacher to facilitate dismantling of master cylinders and vacuum servo units.

13. Teacher to number any 10 components on the stripped vacuum servo units and master cylinders with example masking tape and Koki pen.

14. After practical task has been completed teacher facilitate assembling of all components.

15. Teacher to mark this task while each learner is busy completing it.

Learner:

16. Dismantle vacuum servo unit and master cylinder under teacher’s supervision. (5)

17. Clean all components.

18. Lay out all components in an exploded view on work bench.

19. Identify the 12 numbered components and give the function of each. (24)

20. Examine each component for wear and tear.

21. Compile a condition report on the 12 numbered components. (12)

22. Assemble the vacuum servo unit and master cylinder. (5)

23. Answer the questions in the table below. (4)

24. Learner to record dismantling and assembling steps and all all relevant information.

| 1. | Which component would connect directly to the brake pedal? | 1 |

| 2. | Why is the filler cap on the master cylinder ventilated? | 1 |

| 3. | Why should the reservoir on the master cylinder not be filled higher than the level indicated on the reservoir? Explain | 2 |

Total = (50)

Research task:

ABS braking, traction control and stability programs.

Term: 3 (Phase 3)

Start date: July 2021 (Give early to learners)

Completion date: September 2021

Mark allocation: 50 Term:

Duration of assessment: 12 hours

Name:_____________________ Class:___________

Teacher:

- Teacher to make available any resource material to learners regarding research task topics.

- Research task can be typed or hand written. No learner may be penalised for a hand written task.

Learner: - Research to be done on topics and recorded according to framework given below.

- Obtain research material from media for example – electronic media, magazines, books etc.

- Resources used must be acknowledged at end of task.

- Copies or printouts from electronic media may not be used as is. but relevant information must be extracted from research material to be used.

- Research task can be typed or hand written.

- Work that is plagiarised will not be marked and will need to be resubmitted.

- Use framework below for the task.

| SCHOOL LOGO | ASSESSMENT TASK | LEARNER: ______________ GRADE: ____________ |

| Type of task: | Research |

| Due date: | 31 August 2021 |

| Marks | 50 |

| Topics | ABS brakes, traction control and stability control. |

| Guideline | ||

| Collect data: | Gather all relevant data to complete the task. Keep data you gathered as evidence to be submitted with the task in a folder. Record resources used. | 6 |

| Introduction: | Write introduction on what you want to achieve with the task | 6 |

| Main topics of task: | Operation of ABS and traction control/stability control. Could be systems from light or heavy duty vehicles? | |

| Sub headings: |

| 6 20 6 |

| Conclusion: |

| 4 4 |

| Bibliography | 4 |

Term: 1 - 3

Start date: February 2021

Completion date: September 2021

Mark allocation: 100

Duration of assessment: 16 hours

PRACTICAL LEARNER ASSESSMENT WORKSHEET: (Systems and Control)

- Electricity – conventional ignition system and starting circuit. (50)

- Maintenance (25)

- Forces (25)

Name:_____________________ Class:___________

Teacher:

- Teacher to make all necessary tools and equipment available to learners to complete task.

- Only hand the work sheet to the learner the day you will be testing him/her on the section completed. This must then take place under exam conditions the same as every PAT as prescribed by the CAPS curriculum. PAT must be completed in the workshop on the equipment you supply.

- Take note: this is not a theory task, after learner have been taught and been exposed to all practise he/ she must complete the work sheets.

- An evidence folder in the form of a file could be used to keep each learner work sheets as they complete the sections of the task. Ensure each work sheet it is clearly marked with learners name and surname. This will be submitted as part of evidence during moderation.

- The evidence must be kept in a safe place at school by the teacher.

- Each learner to complete his/her task on their own. No group work allowed

- Teacher to facilitate all facets of task.

- Learners marked as facets are completed.

- Mark sheets and all evidence to be kept by teacher.

- Learners could be called to simulate certain tasks during moderation.

Requirements:

- Complete running engine

- Conventional ignition system / components

- Engine lubrication components (Maintenance)

- Multimeter

- Hand tools

- Work sheets

- Calculator

- Burette or large injection without needle

Learners:

- Learner to complete his/her own task. No group work.

- Investigate the conventional ignition system.

- Use work sheets below to complete tasks

PHASE 4 Conventional ignition system

Work Sheet:

Investigate all the components of the ignition system and answer the questions that follow:

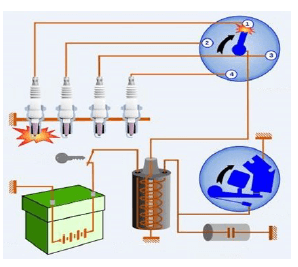

FIGURE 1: Example of conventional Ignition System with contact points

Type of engine: E.g. Ford 1600cc or Toyota 1600cc

Teacher to identify and mark 8 components of the ignition system.

Component

E.g. Spark plugFunction Condition 1.1 (3) 1.2 (3) 1.3 (3) 1.4 (3) 1.5 (3) 1.6 (3) 1.7 (3) 1.8 (3) Use a multi-cylinder engine in the workshop and determine the firing order in a practical manner. E.g. remove tappet cover and position piston no one TDC firing.

Describe in point form process you followed to determine the firing order. (14)Setting of ignition timing. (4)

Testing of components.

Result Rotor (2) Distributor Cap (2) Battery (2) HT leads (2)

Maintenance: Learner to investigate the following: 1 Gear, vane and rotor type oil pumps. Investigate any ONE Dismantle any one of the oil pumps mentioned above and write a condition report on each component of that pump E.g. Rotor pump: Component Condition report 1.1 Inner rotor Scratch marks (2) 1.2 Housing Worn, measured according to specifications (2) 1.3 (2) 1.4 (2) 1.5 (2) [10] Use one of the engines in the workshop.

Investigate and determine the type of oil filtration system (2)

Describe and name SIX components of the filtration system on the engine (6)Find the oil pressure relief valve on the engine. (2)

Describe the type of oil pressure relieve valve that is used by the engine in your workshop. (2)

Explain how the oil pressure relief valve controls the oil pressure. (3)

[25]Forces:

Teacher: Supply necessary tools and equipment to learners to complete the task.

Learner: Each learner does his/her own measurements and record all findings.

No group work.

Measure cylinder bore of engine in workshop with an inside micrometreand record bore size. Engine type must be clearly stated. (3)

Measure length of stroke of same engine and record. (2)

Measure combustion chamber volume using a burette or large injection.

Needle not to be used, but only plastic part with plunger of injection. (5)

Use the measurements you obtained from the engine and calculate the following:

4.1 Swept volume of the engine. (4)

4.2 Total engine capacity in cubic centimetres. (2)

4.3 Compression ratio of the engine. (3)

Define the following:

4.4 Torque (2)

4.5 Free volume (2)

4.6 Mean effective pressure (2)

[25]

TOTAL PHASE 4 = 100 MARKS